Super-Low Reflective Coating

NSG's unique inorganic–organic hybrid technology has created this Super-Low Reflective Coating that contributes to the improvement of the image quality of photos and videos, and the noise reduction of sensing devices.

Product summary

The Super-Low Reflective Coatings from NSG exhibit superior low reflective performance/high transmittance compared to conventional technologies such as vapor deposition. Our proprietary coating materials provide stable low reflection performance at large angles of incidence. Coating is available in a wide variety of optical components including those with flat and curved surfaces, glass and resin.

For camera module, the light reflection on lens or filter surfaces can generate noises (ghost and flare), but this can be significantly reduced through NSG's Super-Low Reflective Coating and helps to improve image quality and sensing accuracy.

Features of Super-Low Reflective Coating

NSG's Super-Low Reflective Coating is a coating with high anti-reflection performance that can be applied to curved surfaces such as lenses and cover glass, as well as flat glass surfaces.

Superiority of Super-Low Reflective Coating

Achieves both Super-Low Reflective performance and Low Incident Angle Dependency.

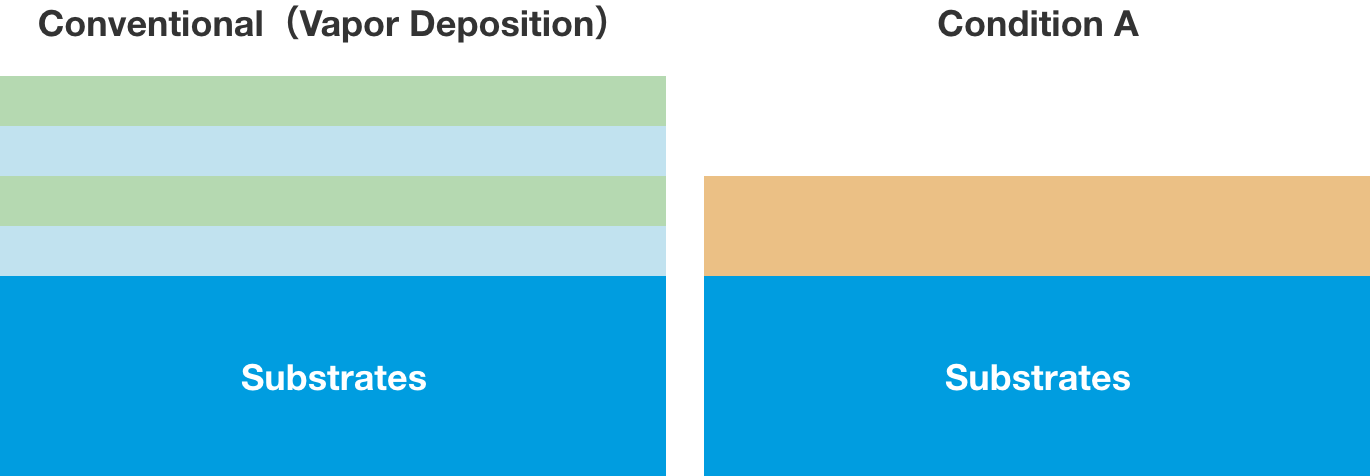

It achieves superior low reflectivity and high transmittance compared to conventional technologies such as vapor deposition coating. Further, NSG's original materials can realize low reflection over a wide wavelength bandwidth with a smaller number of layers. This significantly decreases the incident angle dependency which is a challenge in vapor deposition coating.

Optical Design Flexibility

Super-Low Reflective Coatings are materials that can be adjusted in a wide range of refractive index. Our line-up includes products with low and medium refractive index appropriate for targeting applications. Peak wavelength and bandwidth can be adjusted as well.

Coating to a variety of Optical Components

Taking advantage of liquid materials, coatings can be applied to curved surfaces as well as flat surfaces. This can be used for resin and other materials surfaces as well as glass (*1).

High Reliability

The use of inorganic materials as the main raw material gives the product excellent reliability (temperature, humidity, etc. *2).

*1 Please consult us for the available resin materials.

*2 Reliability test conditions for general optical components

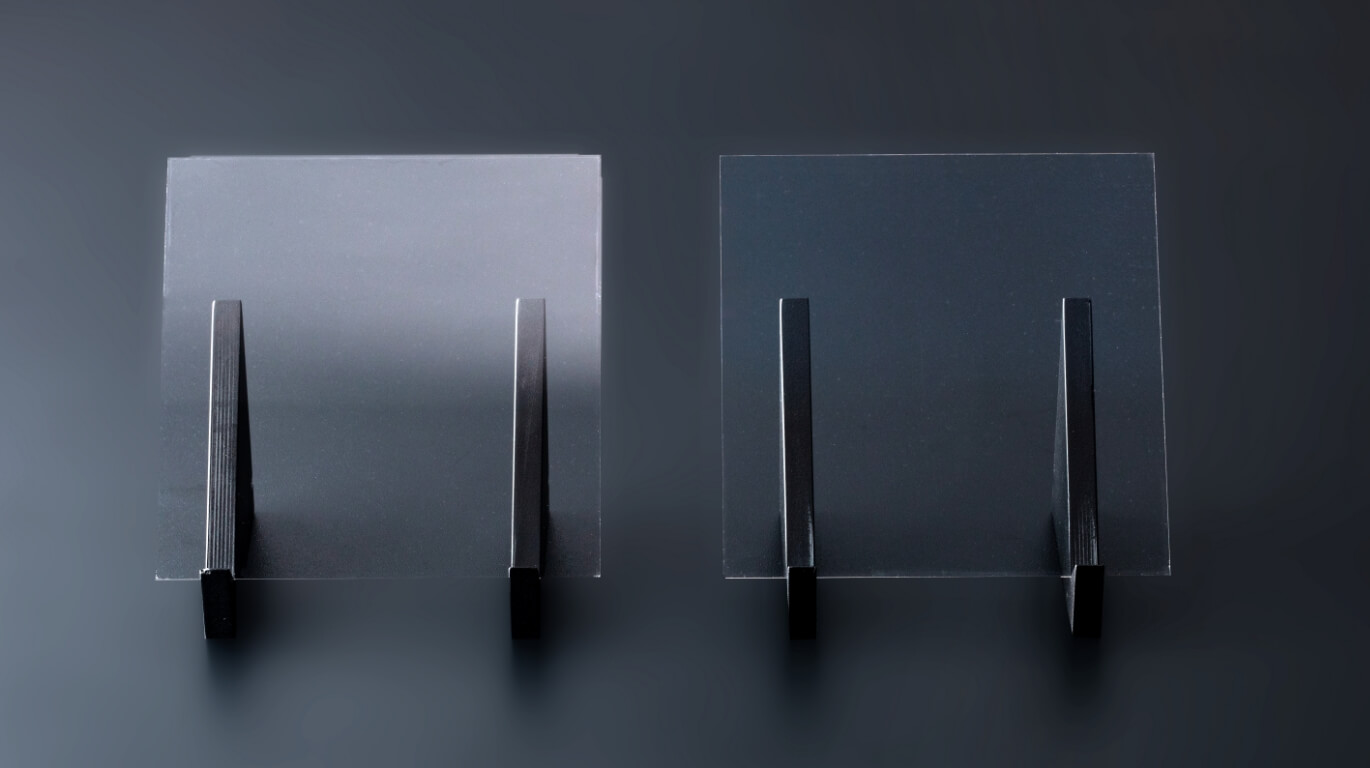

Left: Without Super-Low Reflective Coating / Right: With Super-Low Reflective Coating

Effect of Super-Low Reflective Coating

Improvements in Camera Image Quality and Sensing Accuracy

Light reflection on the surface of camera lenses and filters can cause ghost and flare, and this negatively affect photo and video image quality. The NSG's Super-Low Reflective Coating significantly reduces ghost and flare (noise), and helps improving image quality and sensing accuracy.

Application to Wide range of Environments

As it uses inorganic materials, it has excellent reliability and can be applied to optical components such as lenses for equipment installed outdoor use.

Example of Ghost Image

Example of Ghost-free Image

Super-Low Reflective Coating

Reflectance and Transmittance (e.g., glass)

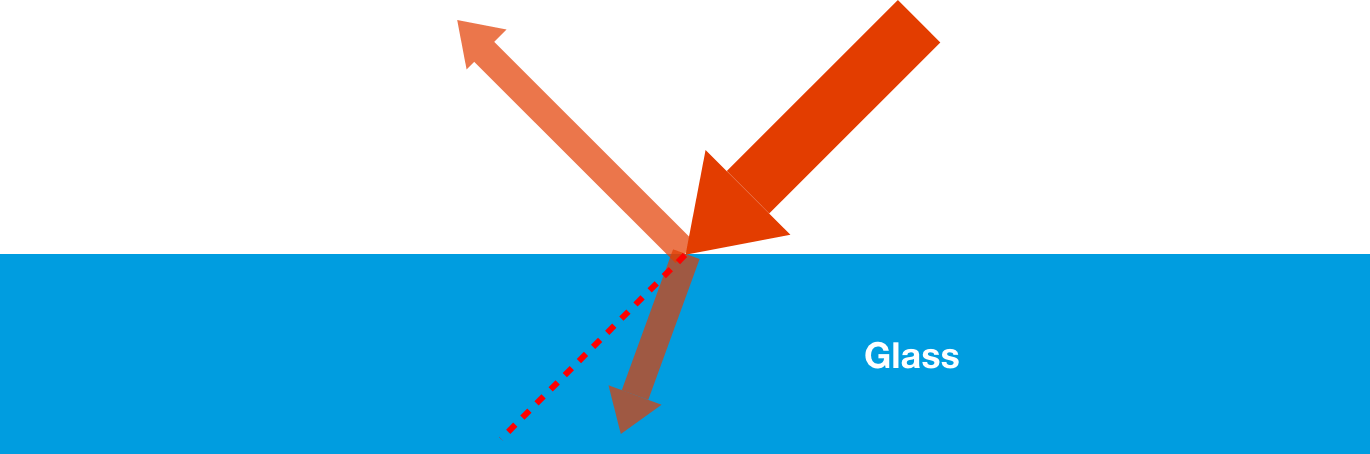

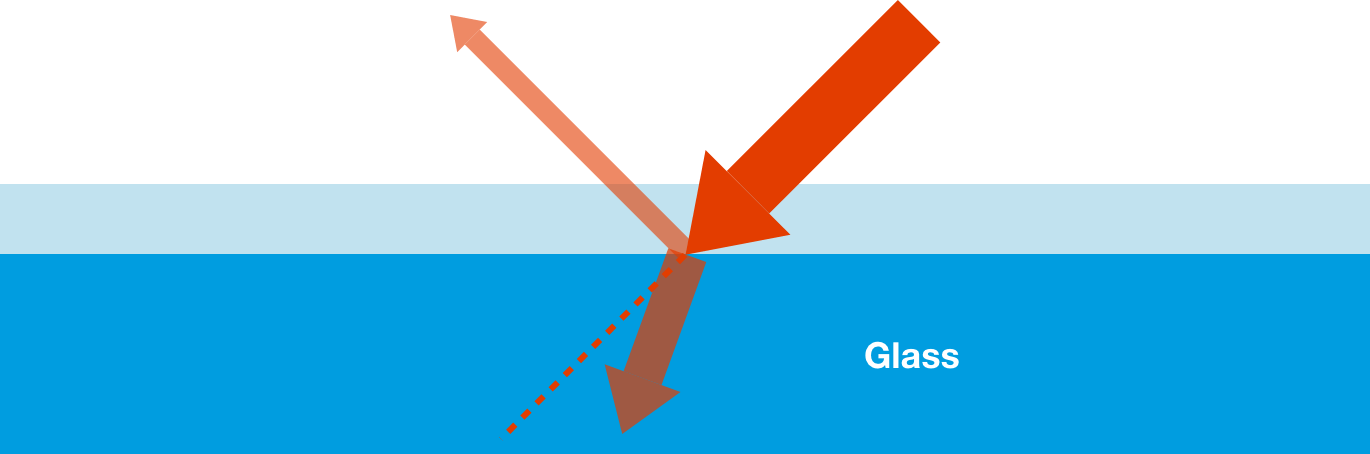

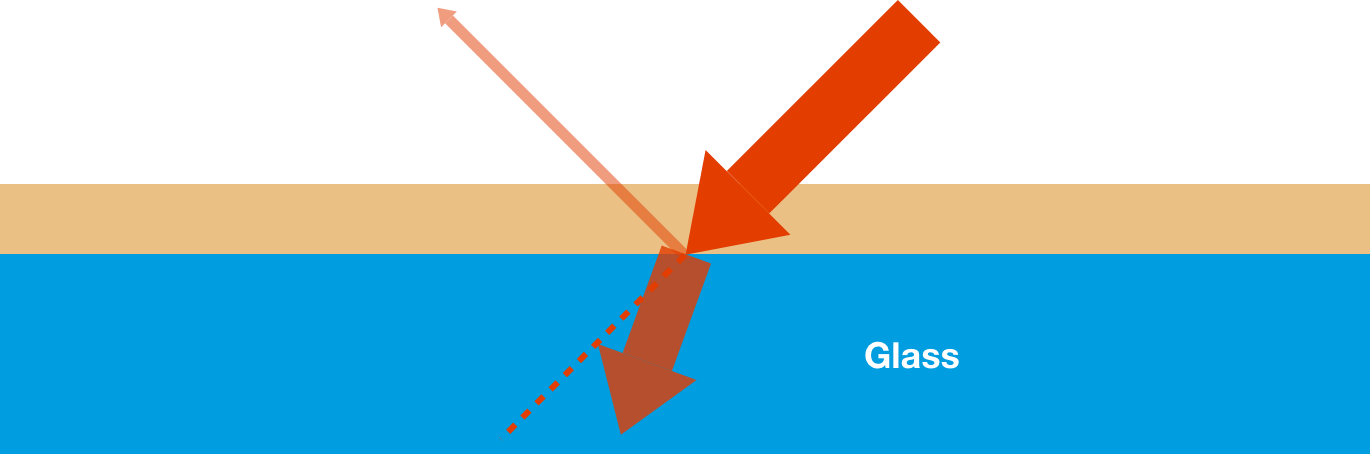

Although light travels straight with a fixed speed through a uniform medium such as glass, its speed and the direction of travel change when light enters a different material at an angle. This is called refraction, and the degree of change is expressed using the refractive index. This is a numerical value unique to each medium. Light can be reflected on different interfaces at a certain rate, which can be addressed by the refractive index unique to particular medium.

Anti-reflection coatings consist of single or multilayered thin films with different refractive indices. If the layers have different refractive indices, they cancel each other out to reduce the reflected light (Figure 1). The glass appears to become invisible as the surface reflection is reduced.

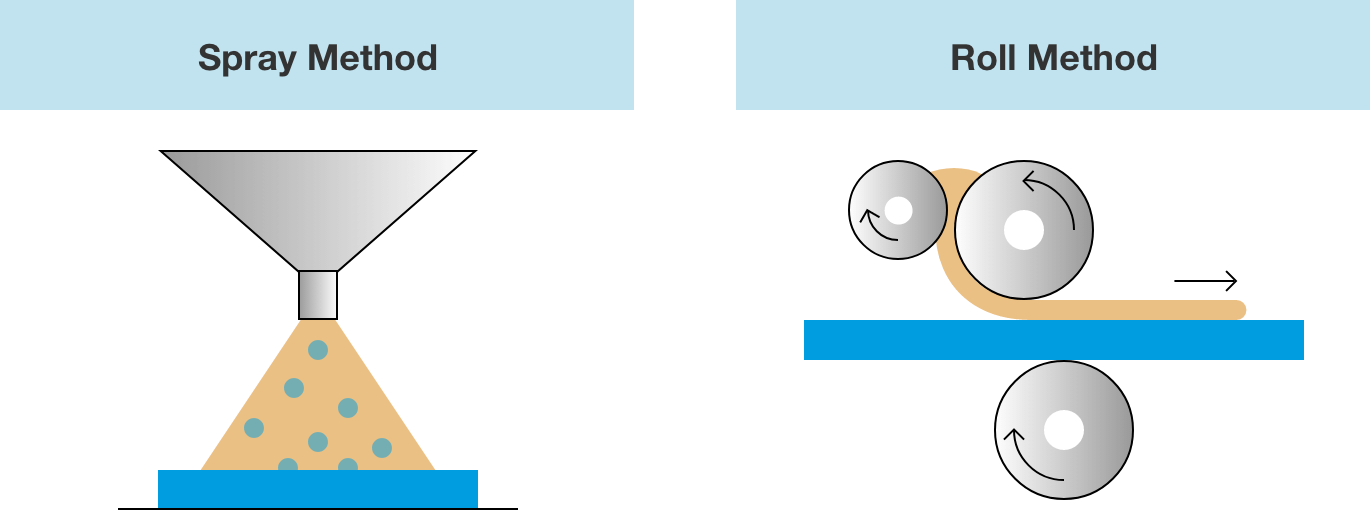

NSG's Super-Low Reflective Coating

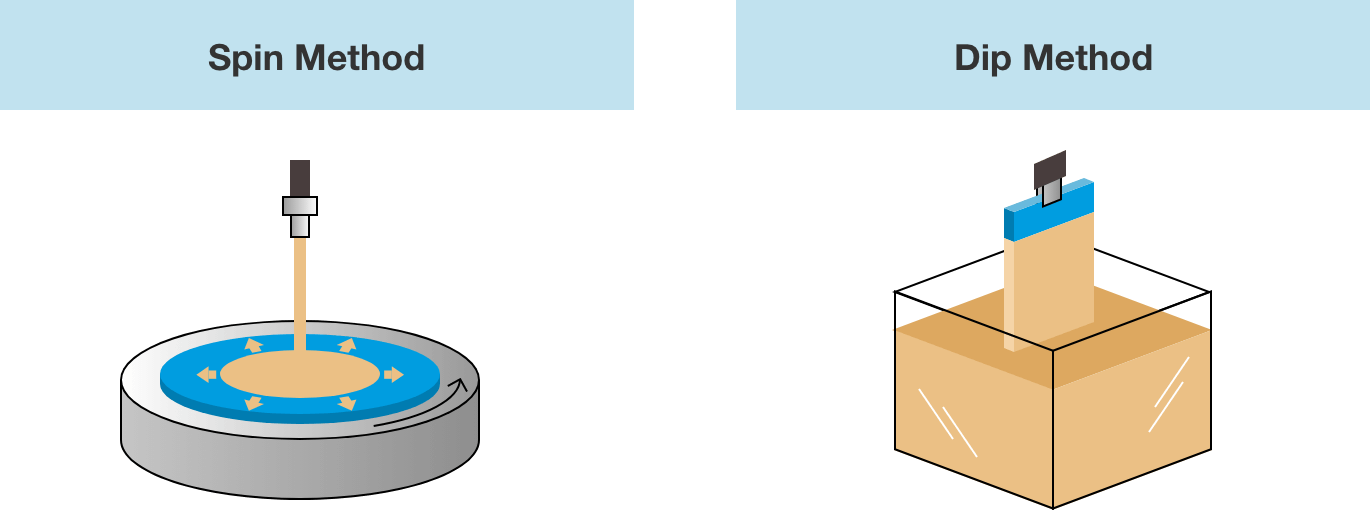

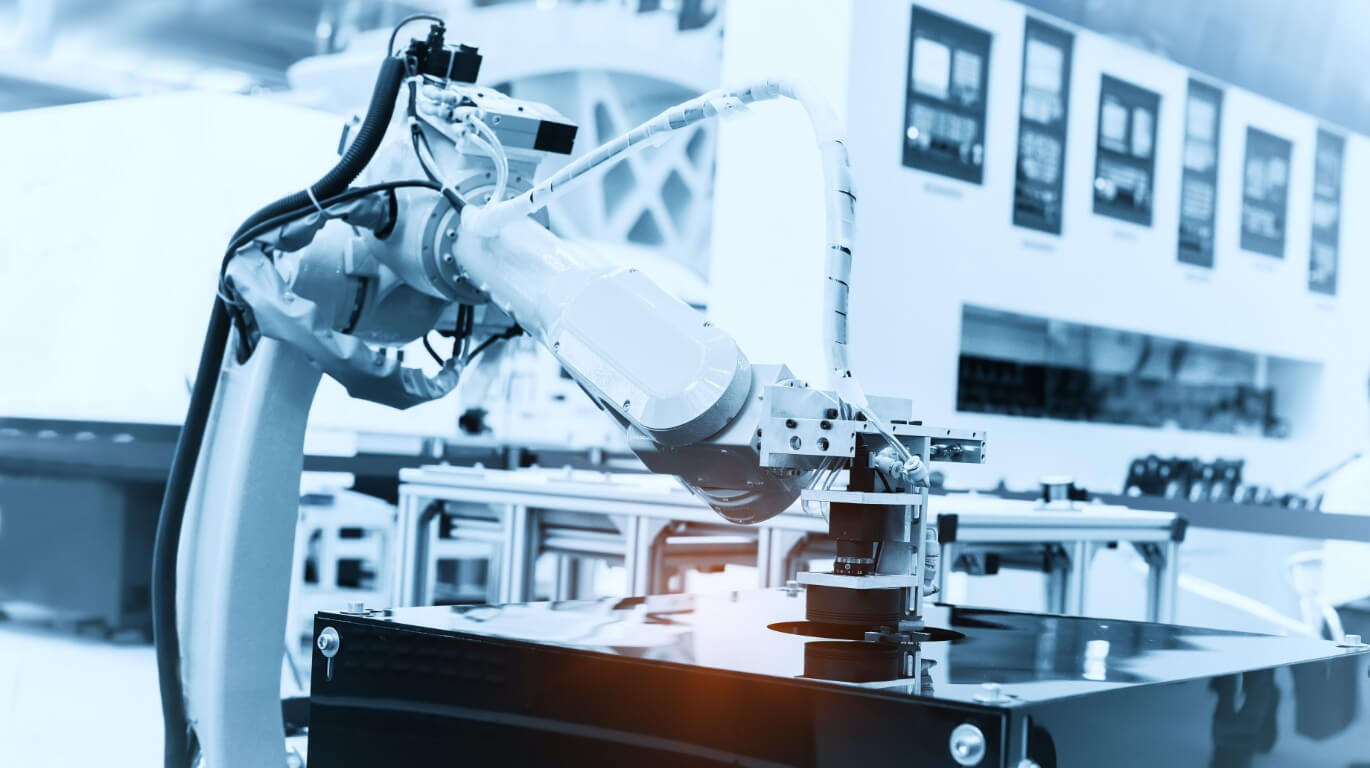

NSG's proprietary coating materials and optical design know-how, by adjusting the refractive index to suit the material, such as glass or resin, enable a significant reduction in reflectivity. The coating has been devised in a way that general-purpose methods such as spin and spray coating (Figure 2) can be used.

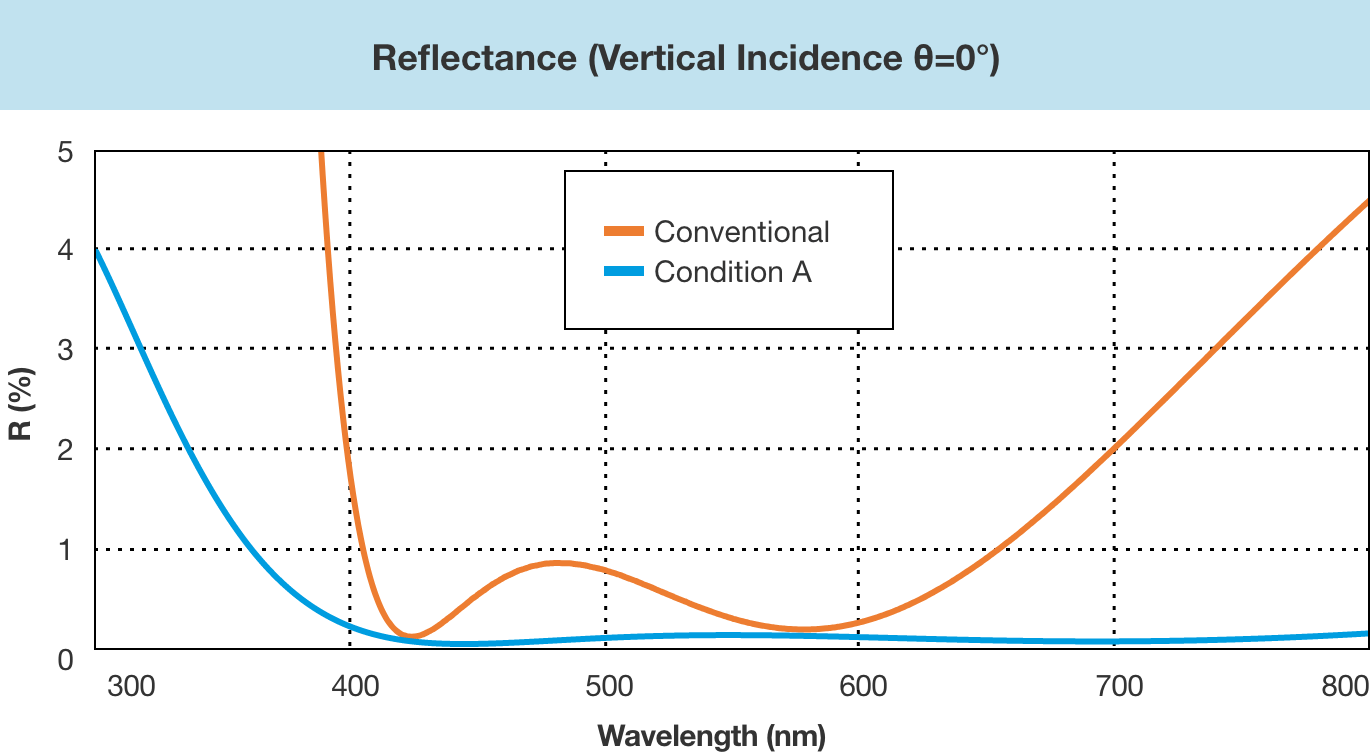

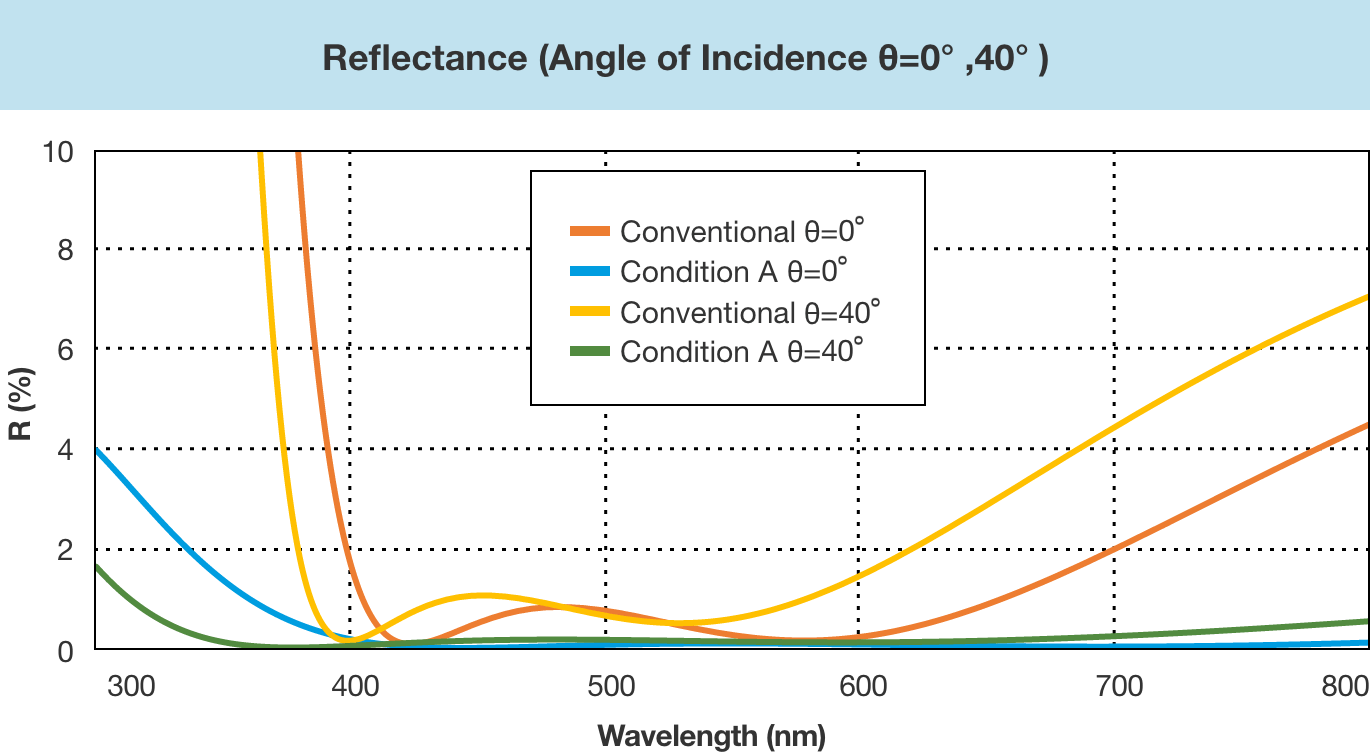

The way the anti-reflective (AR) coatings generally work is to reduce reflectivity only on specific wavelengths. However, NSG's Super-Low Reflective Coatings enable low reflection over a wide wavelength bandwidth and can achieve this using fewer layers. This feature is highly effective when there is a change in the angle of incidence (Figure 3).

In this example, we can see the data obtained when applying Super-Low Reflective Coating to just one side of the substrate.

For Glass only

Figure 1: Comparison of Reflection and Transmission

Conventional Vapor Deposition Coating

NSG's Super-Low Reflective Coating

Figure 2: Examples of Coating Methods

Figure 3: Reflectance and Incident Angle Dependency

Expansion to New Application

NSG's Super-Low Reflective Coatings are being used and considered for use in camera modules and other optical products. And expected to be used in new ways such as in wearable devices and optical devices with lasers and LEDs in the future.

Example of Wearable Devices

Example of Laser Devices

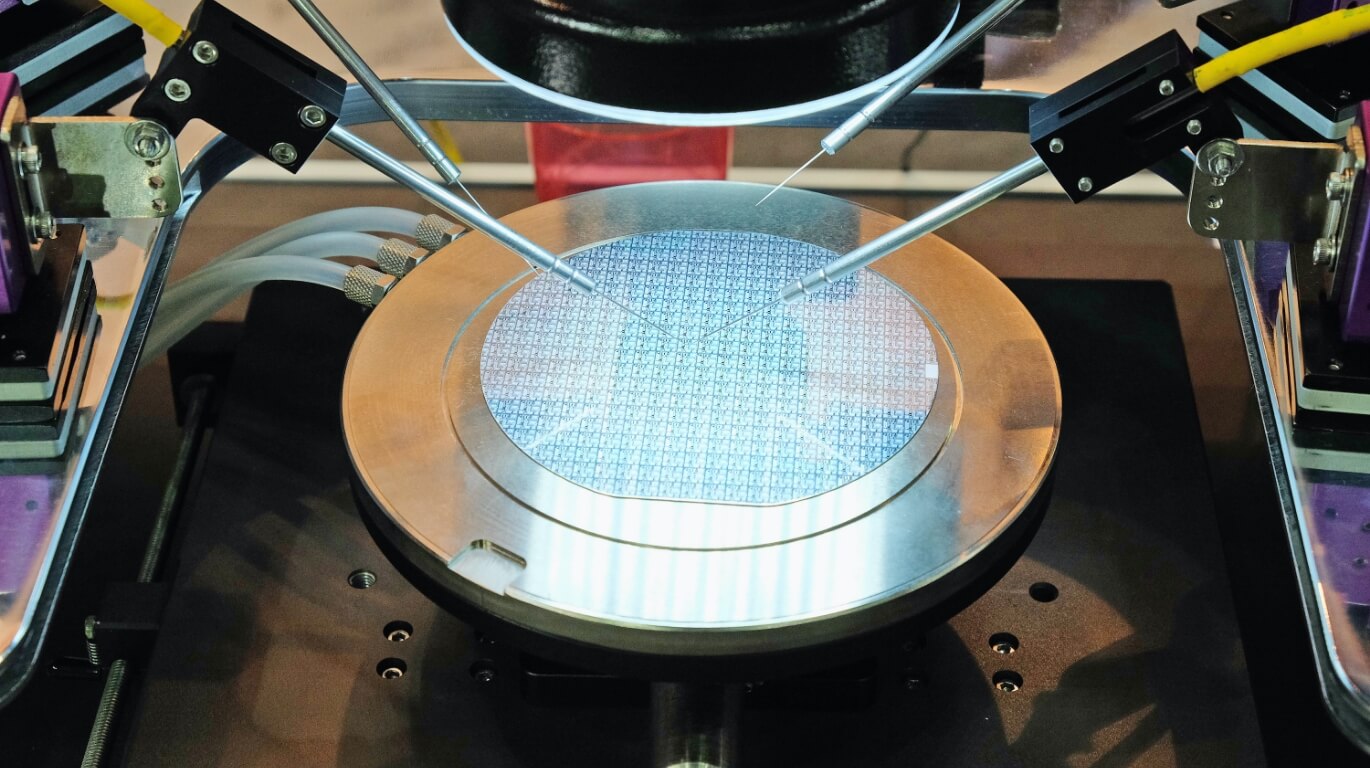

Example of Semiconductor Manufacturing

Expansion in Scene of Use

NSG’s Super-Low Reflective Coating is an ideal solution for anti-reflection. Especially applicable to items for which anti-reflection coatings have been achieved by vapor deposition method, including camera lenses and infrared (IR) cut filters. Conventional vapor deposition method has difficulty to coat on curved surfaces, but NSG's Super-Low Reflective Coating can be applied to such surfaces. And expected to be applied for many scenes in a near future.

Glossary

Anti-reflection Coating (AR coating)

This is a thin film that is attached to the surface of a material, such as glass, to decrease the light reflection. Typically, multiple films with different refractive indices are laminated to suppress surface reflection and improve transmittance.

(AR: Anti-reflection)

Dependence on Angle of Incidence

This is the relationship between the light angle of incidence and its reflectance on a material such as glass. Generally, the larger the angle of incidence, the greater the reflectance.

Ghost, Flare

This is a nonexistent image that results from strong light entering the lens during photography. Ghosting is like a ball of light, when capturing with backlighting, that forms away from the strong light while flare is an general whitish phenomenon that occurs when capturing with backlighting.

Infrared (IR) Cut Filter

Filter for suppressing infrared (IR) light transmission. Digital imaging device can capture both visible and invisible wavelength when IR cut filter is not utilized. This causes the differences of color reproducibility from what human sees. By placing an IR-cut filter in front of the image sensor, it is possible to output a close color reproducibility as seen by the human eyes. (IR: Infrared).

Vapor Deposition Coating Method

This is a method of forming a thin film by evaporating metals and oxides in a chamber, thus causing them to adhere to the surface of a material. TiO2 or SiO2 is used for optical thin films.

FAQ

Can you provide a sample?

We are able to provide samples coated on glass substrates, etc.

Is it possible to adjust the refractive index?

Although custom adjustments can be available depending on conditions, technical discussions and prototyping will be required.

Is it possible to coat on the specified material or product?

Technical meetings and trials will be used for its feasibility.

Is it possible to get coated lenses or substrates?

We basically do not supply coated lenses or substrates except sample preparation.

What is the difference when using the anti-reflection film produced by the vapor deposition coating method?

In General, Anti-reflection coating is a multi-layered metal thin film formed by vacuum evaporation. This uses the effect of interference where light cancels each other out to reduce the reflected light. NSG's Super-Low Reflective Coating reduces the amount of reflection at the interface itself through the low refractive index layer.

Can you tell us about the price, delivery period, and how to obtain it?

This varies according to the coating method and the amount of annual or monthly quantity. We would be happy to consult with you on this issue.

Is it possible to use my own spin coating equipment or spray coating equipment?

Whether coating is possible or not depends on the capacity of the device. We are able to offer reference information and support.

Is it possible to be mixed with other materials?

In principle, this cannot be mixed with other materials.

Can you provide a sample of the coating materials?

Although we do not provide samples of materials in principle, we would be happy to discuss with you how we can meet your needs with the provision of samples.

Are you compatible with RoHS, REACH, and the Chinese version of RoHS?

We have confirmed these regulations.

Can you tell me which sizes can be coated?

It is currently possible to coat compact optical products, such as camera lenses, etc. Although theoretically, it may be possible to coat large areas such as window glass, this will tend to be expensive for the performance you are looking for.