Hierarchy Nanoporous Layer Glass (HNL GLASS)

Chemically strengthened glass that combines low reflectivity and high transparency, with a nano-porous layer on the glass surface.

Product summary

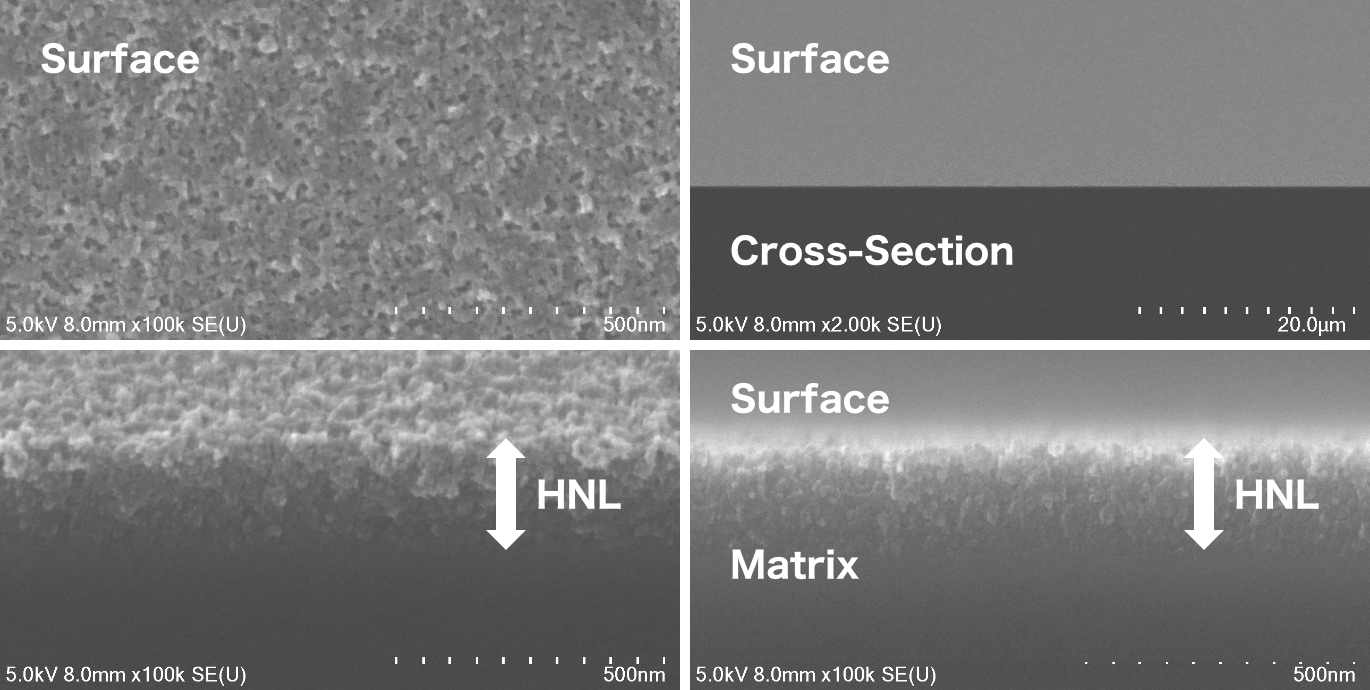

NSG's hierarchical nano-porous layer glass (HNL glass) is a surface-modified porous glass composed of alumina and silica-rich components with a thickness of several hundred nanometers. It features a gradient structure where mesh-like pores, sized at several tens of nanometers on the surface of chemically strengthened glass, gradually decrease in size toward the interior. The gradual change in refractive index due to this nano-sized graded structure provides low reflection and high transmittance of visible light, and has higher mechanical strength than conventional chemically strengthened glass. Additionally, by utilizing its superhydrophilic surface and loading functional nanoparticles into the pores, it holds potential for development into new functional materials (e.g., exhibiting high water-repellent performance when a water-repellent agent is applied).

Features of HNL glass

NSG's HNL glass, which can be processed using environmentally friendly weak alkaline etching, has the following characteristics:

・Low reflectivity and high transparency in visible light

・Greater mechanical strength than conventional chemically strengthened glass

・Hydrophilic glass surface due to nano-level gradient structure

・Enhancement of functional films utilizing the pores

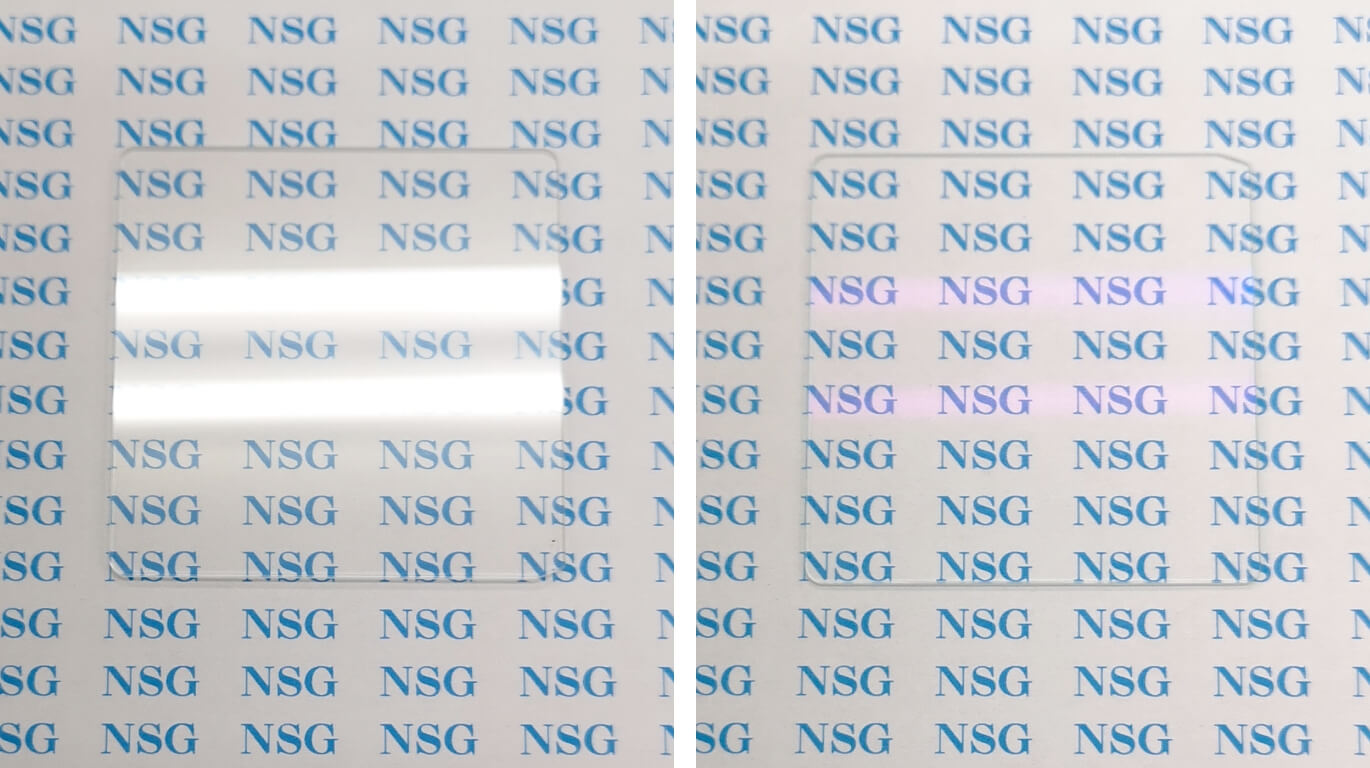

High Light Transmittance

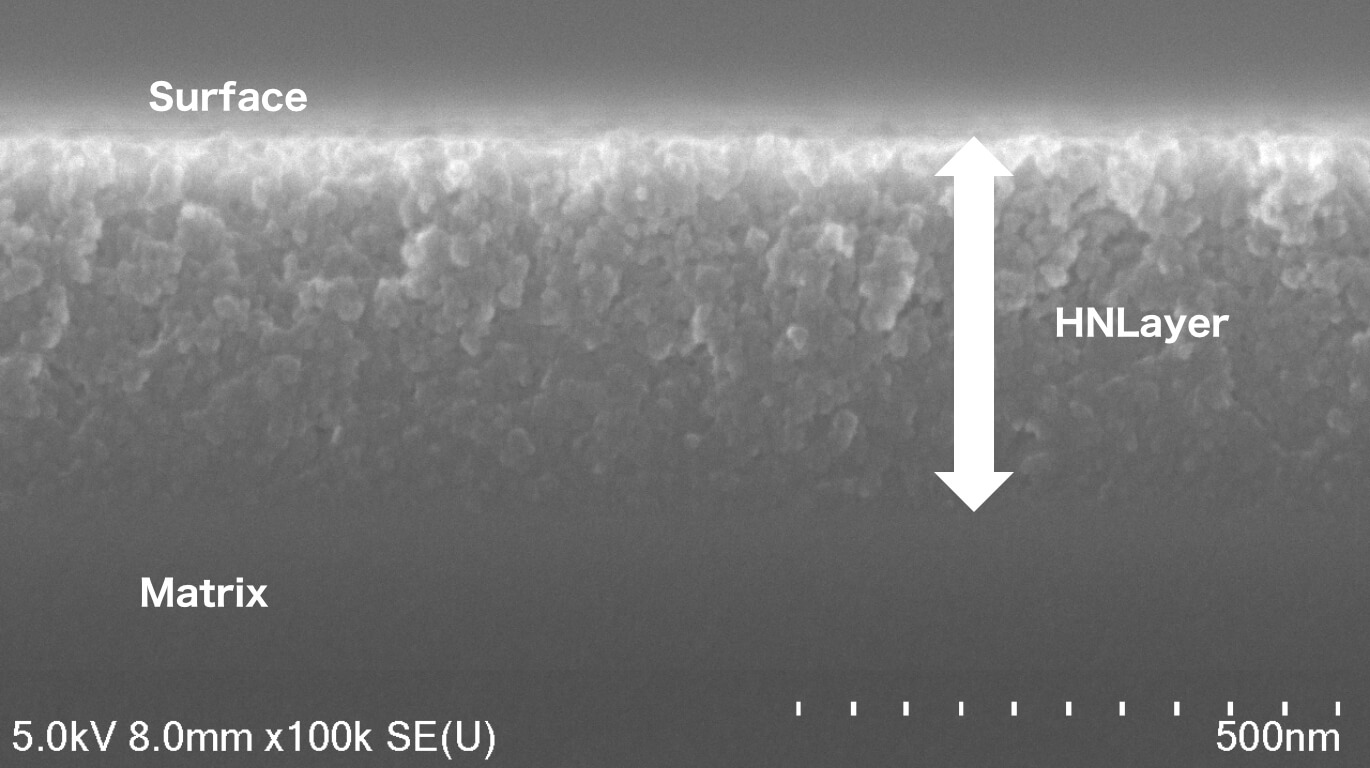

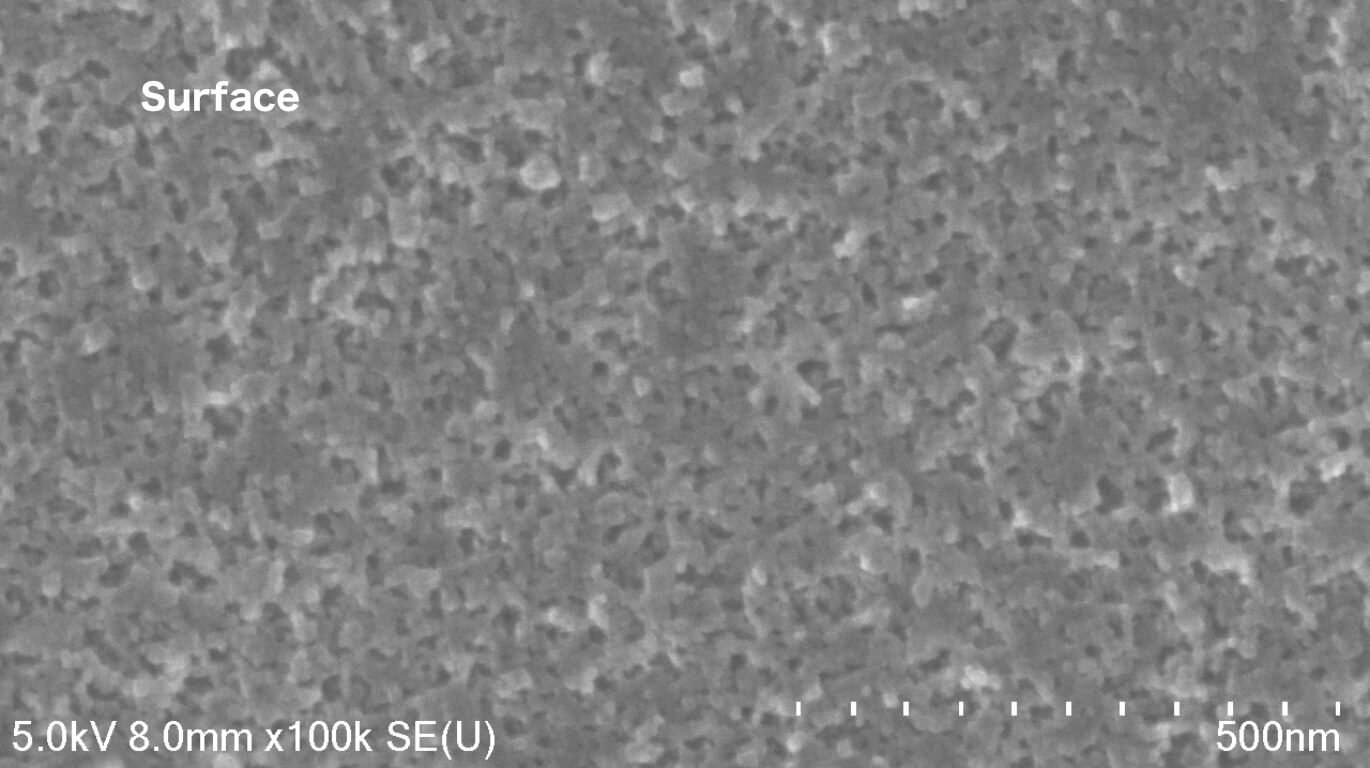

The hierarchically nanoporous structure formed directly on the glass surface does not have a clear boundary between the porous layer and the base material. Therefore, it brings about a gradual change in the refractive index due to the gradient structure of the pores, exhibiting low reflectivity and high transmittance in the visible light region.

Reflection of fluorescent lamps (reflection performance) and transmittance (Left: untreated glass, Right: HNL glass)

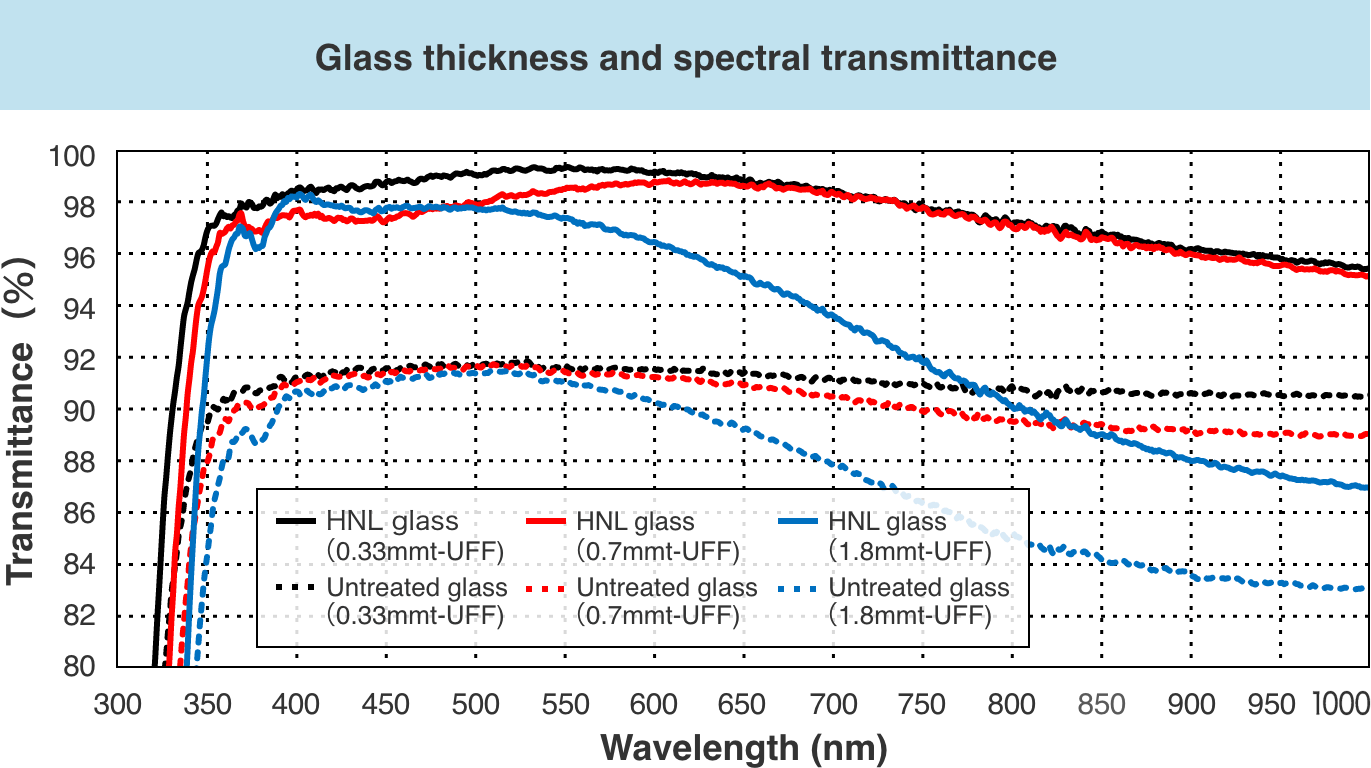

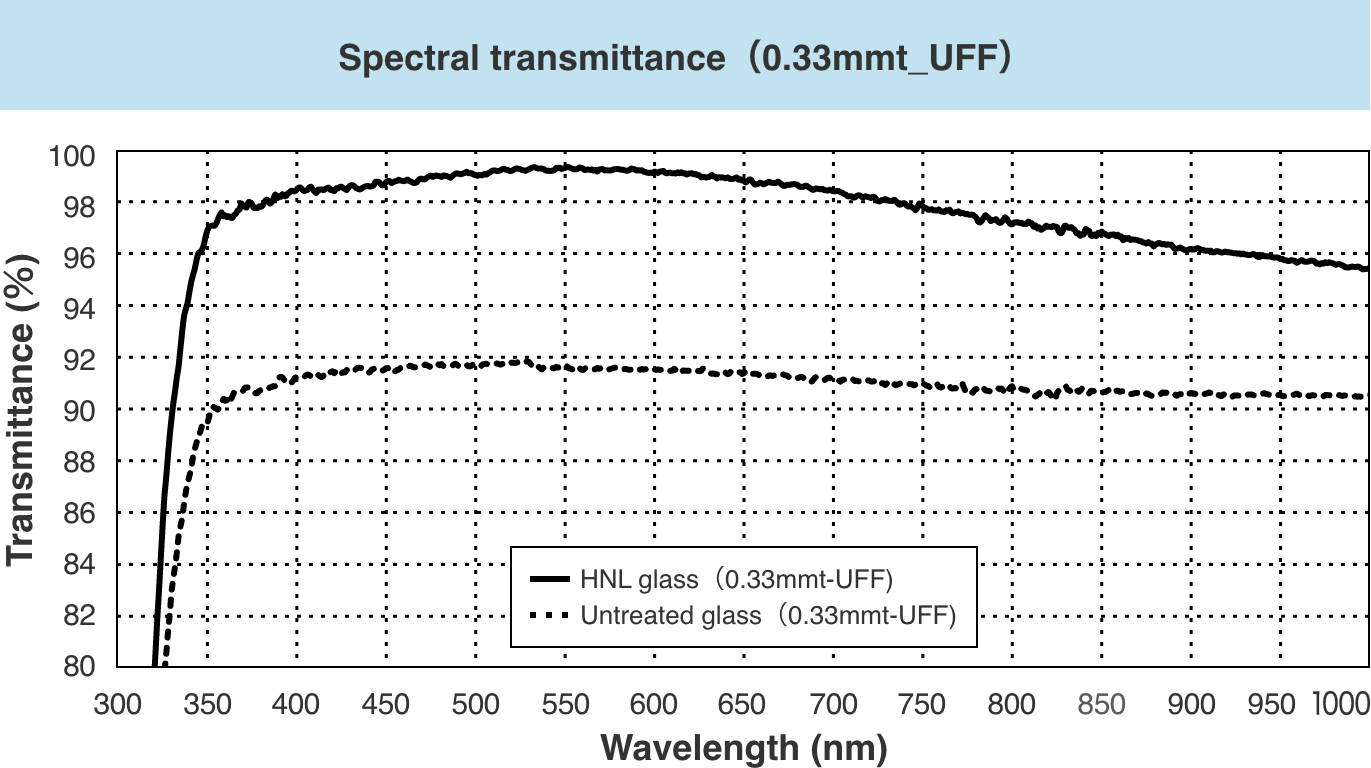

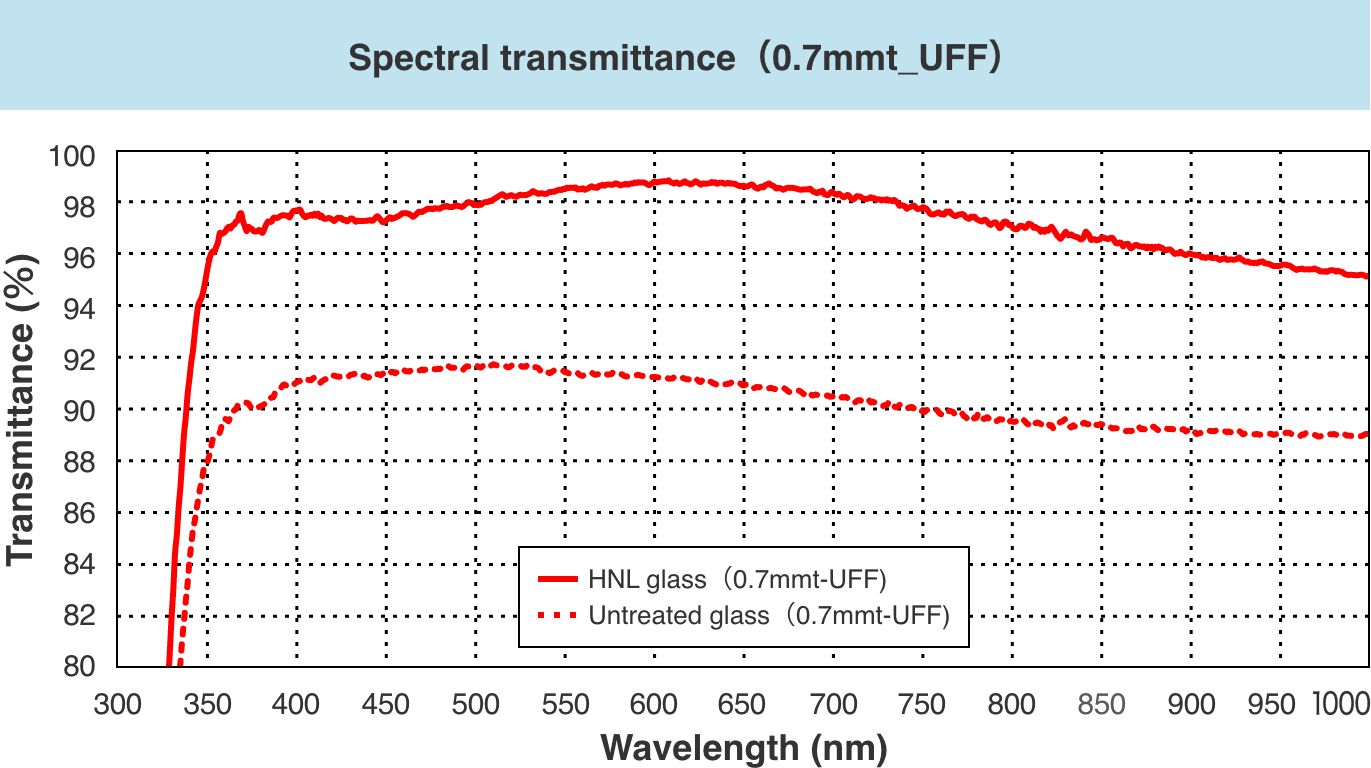

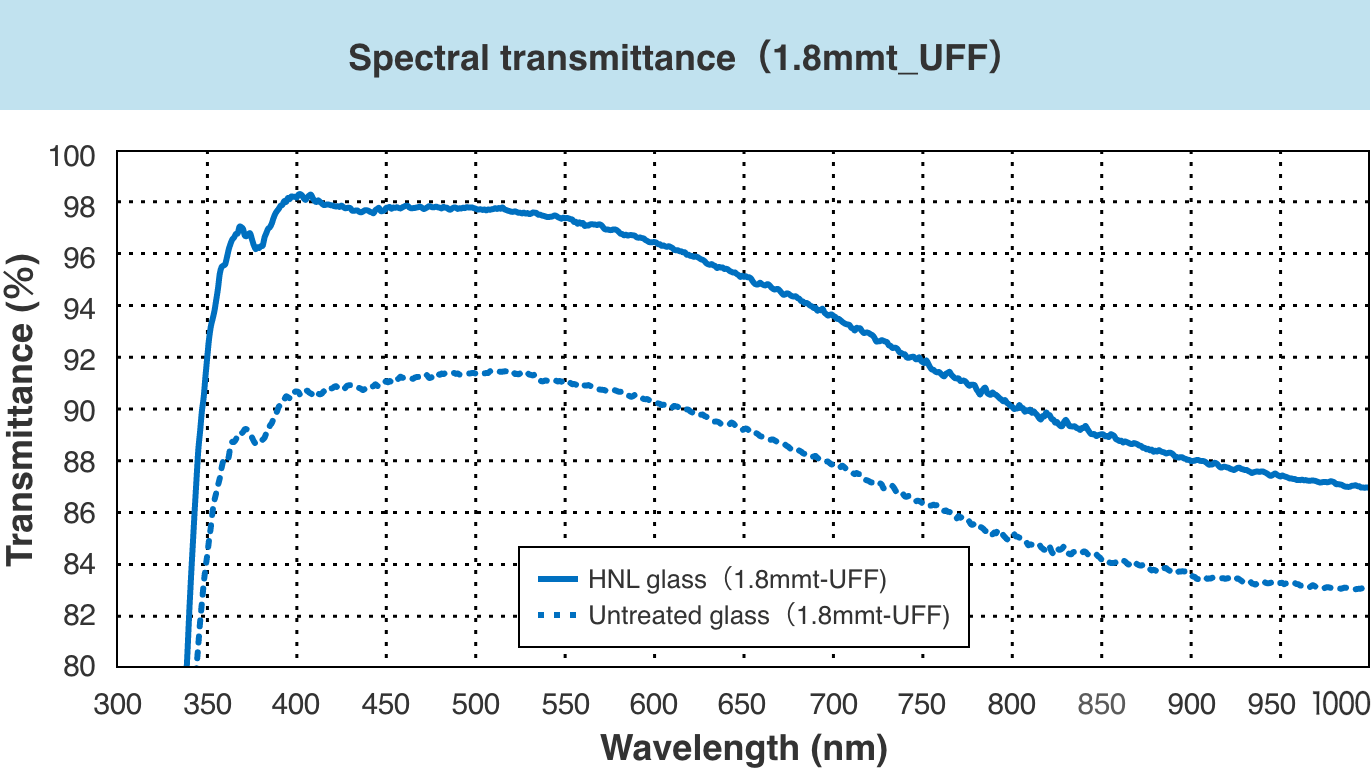

Spectral transmittance before and after HNL formation and glass thickness

SEM images (cross-sectional image)

SEM images (surface image)

Luminometer experiment (no glass)

Luminometer experiment(untreated glass)

Luminometer experiment (HNL glass)

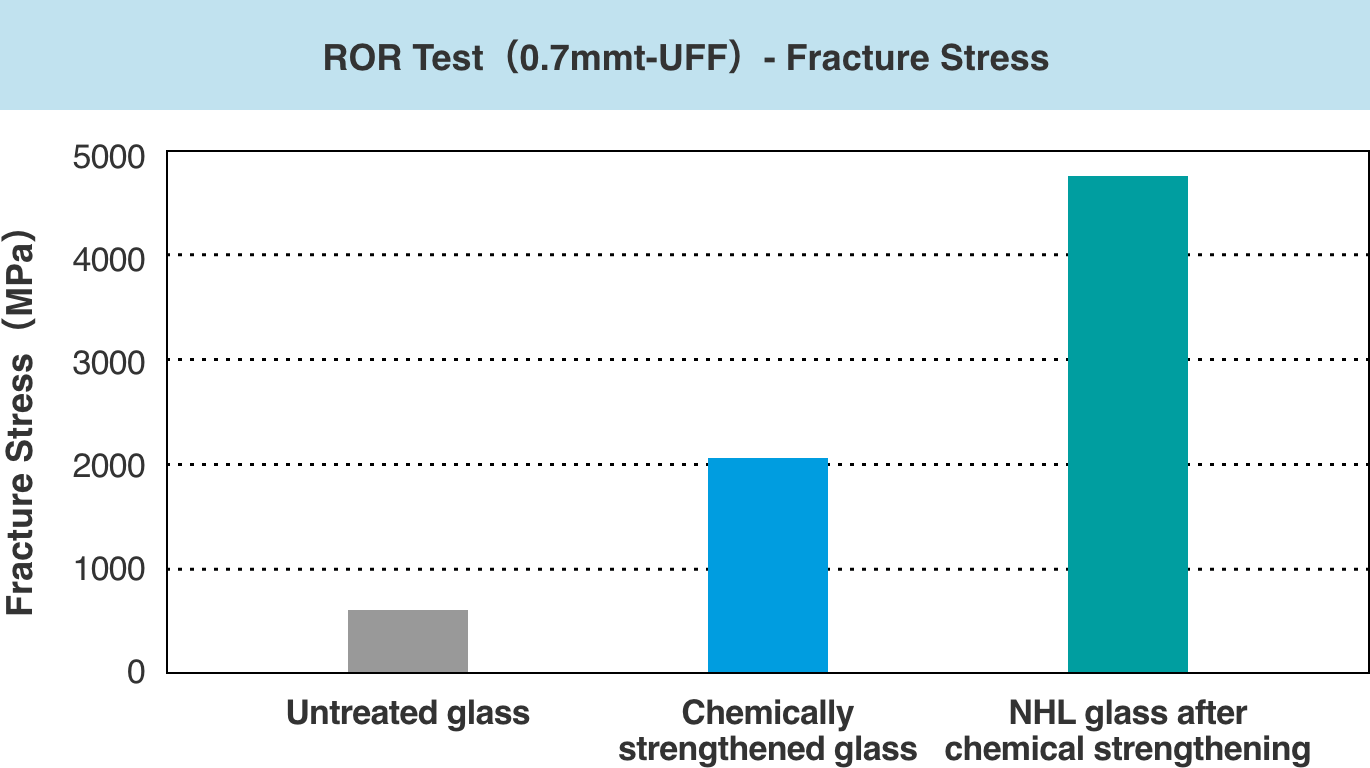

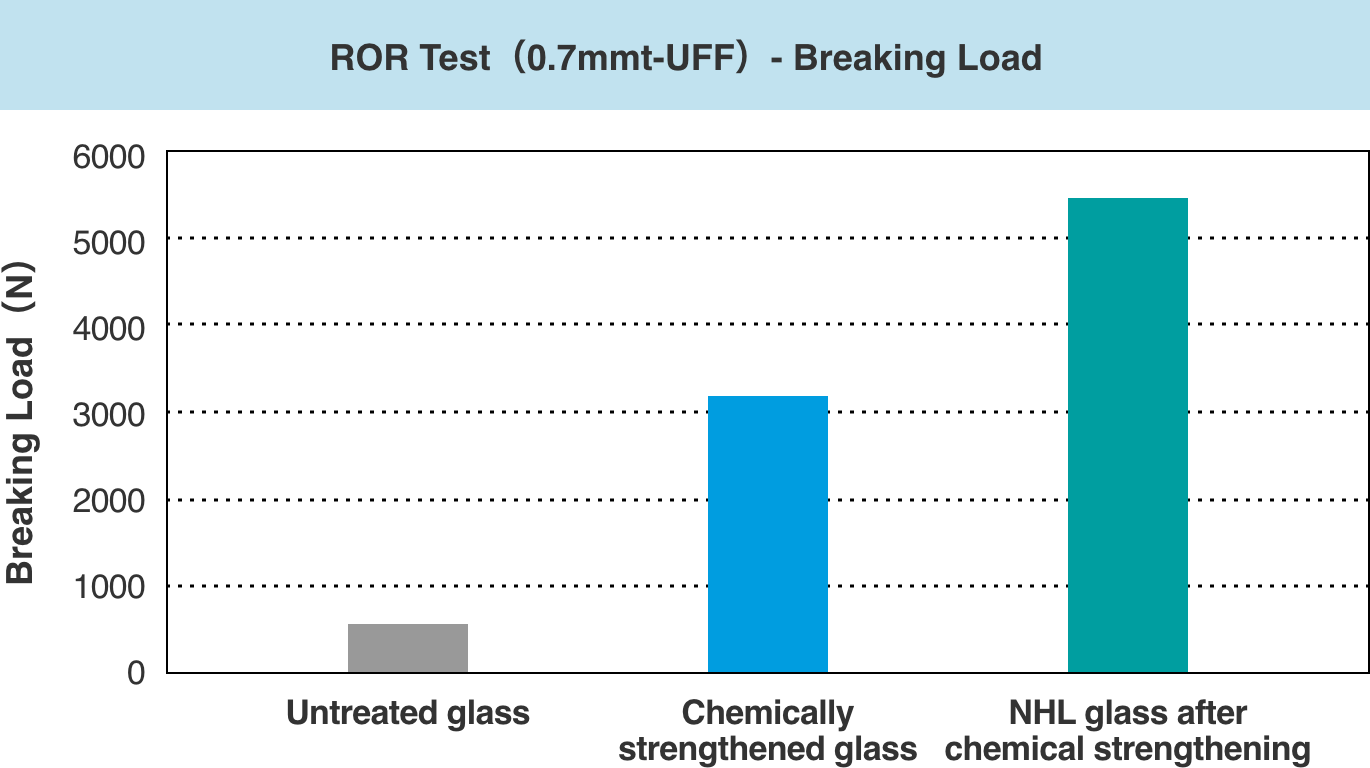

Fracture Strength

By forming a nanoporous layer directly on the surface of chemically strengthened glass, the fracture strength can be increased compared to conventional chemically strengthened glass.

Comparison of ROR strength between untreated chemically strengthened glass and chemically strengthened glass with a hierarchical nanoporous structure.

ROR Strength Test_Chemically strengthened glass

ROR Strength Test_HNL glass after chemical strengthening

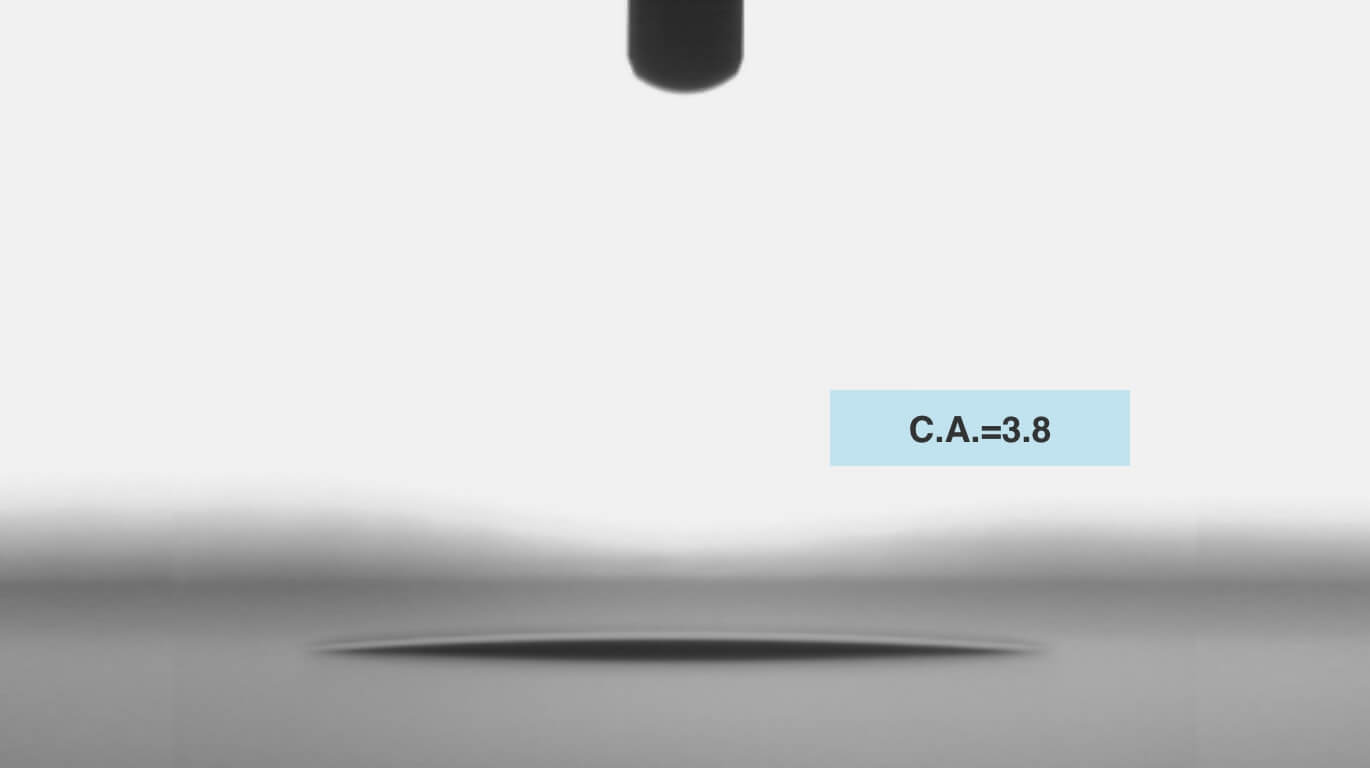

Superhydrophilicity

Due to the nanolevel gradient structure, the glass surface exhibits a low contact angle of less than 10 degrees (superhydrophilicity).

Contact angle demonstrating superhydrophilicity

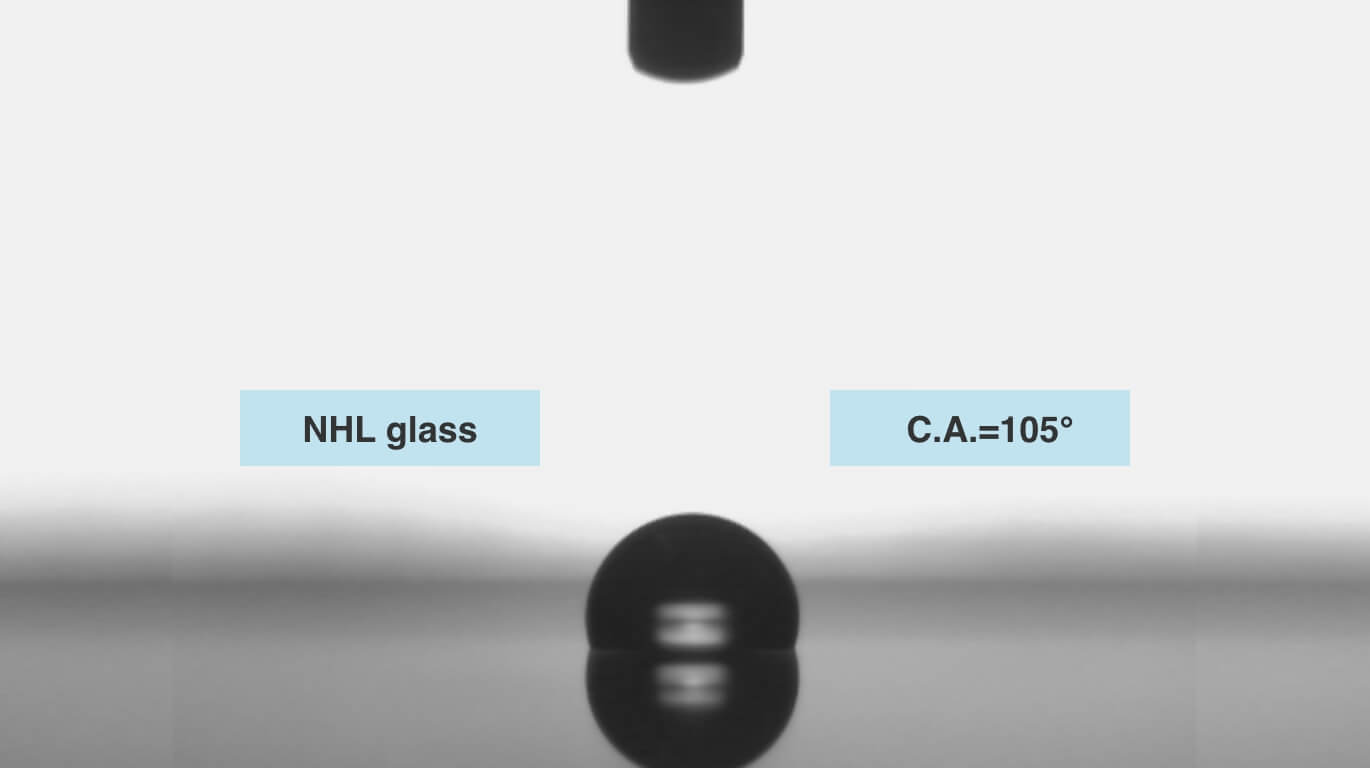

Example of combination with functional film utilizing pores (when carrying water repellent agent)

By loading functional films (nanoparticles) into the pores of HNL glass, development into new functional materials is expected.

For example, when a water-repellent agent is loaded, the transmittance of untreated glass decreases. However, the transmittance of HNL glass is higher than that of untreated glass because the water-repellent agent does not fill the deep pore spaces of HNL glass, and the water repellency is also higher.

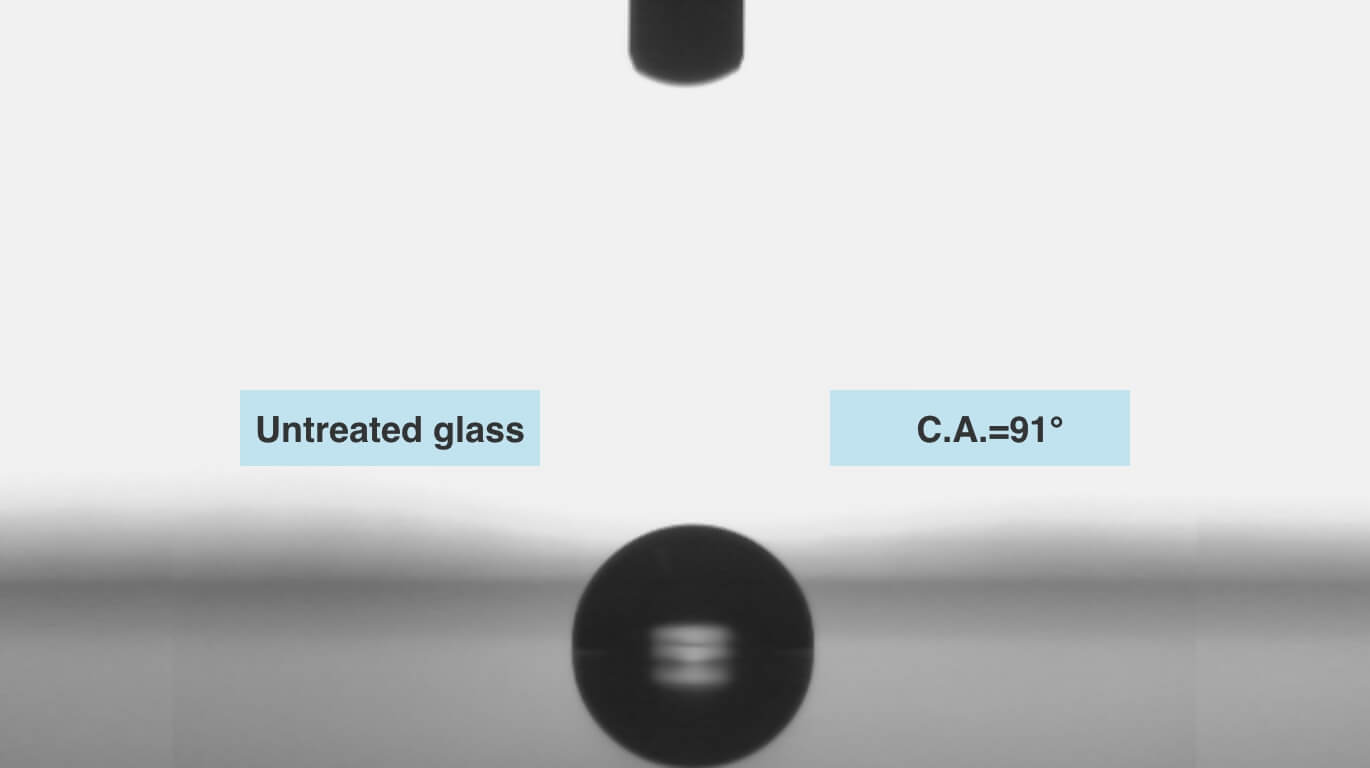

Contact angle after spray application of a commercial water repellent (Glaco) on untreated glass

Contact angle after spray application of a commercial water repellent (Glaco) on HNL glass

Improvement of Transmittance

NSG's HNL glass can be processed with an environmentally friendly weak alkaline etching. Transmittance can be significantly improved by forming hierarchical nanoporous layers (HNL) in a short period of time on inexpensive soda-lime glass that can be mass-produced.

Spectral Transmittance (0.33mmt UFF)

Spectral Transmittance (0.7mmt UFF)

Spectral Transmittance (1.8mmt UFF)

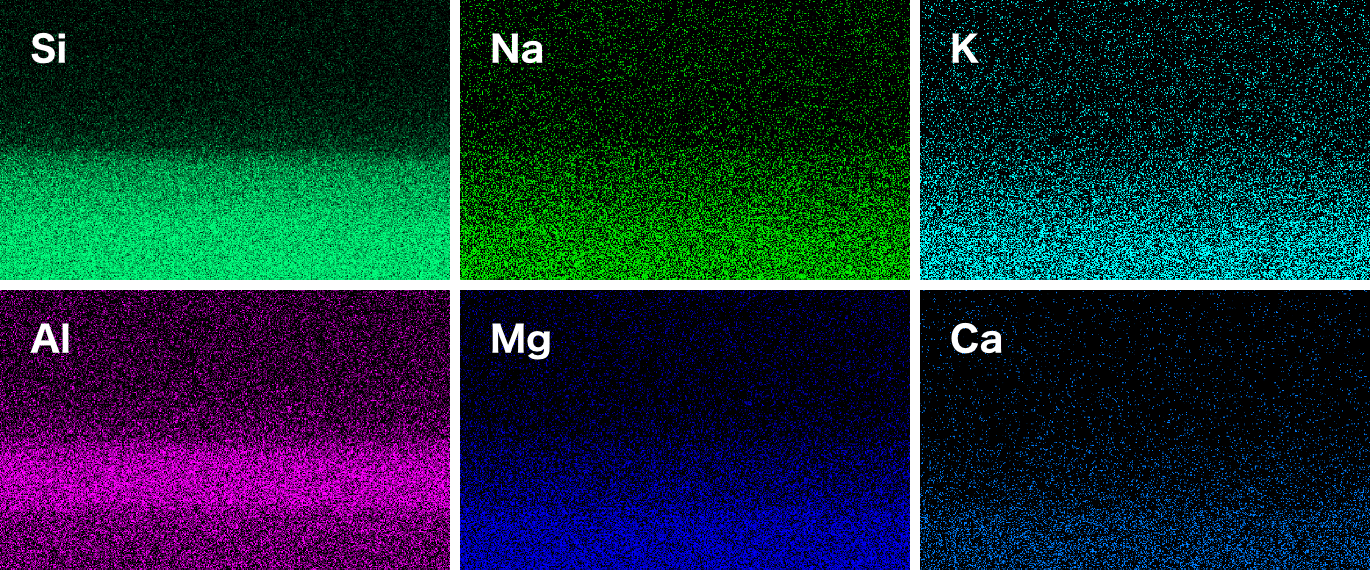

Boundary Interface of the Porous Layer

The hierarchically nanoporous structure formed directly on the glass surface does not have a clear boundary interface between the porous layer and the base material. Therefore, it brings about a gradual change in the refractive index due to the gradient structure of the pores, exhibiting low reflectivity and high transmittance in the visible light region.

SEM Images (Porous Layer)

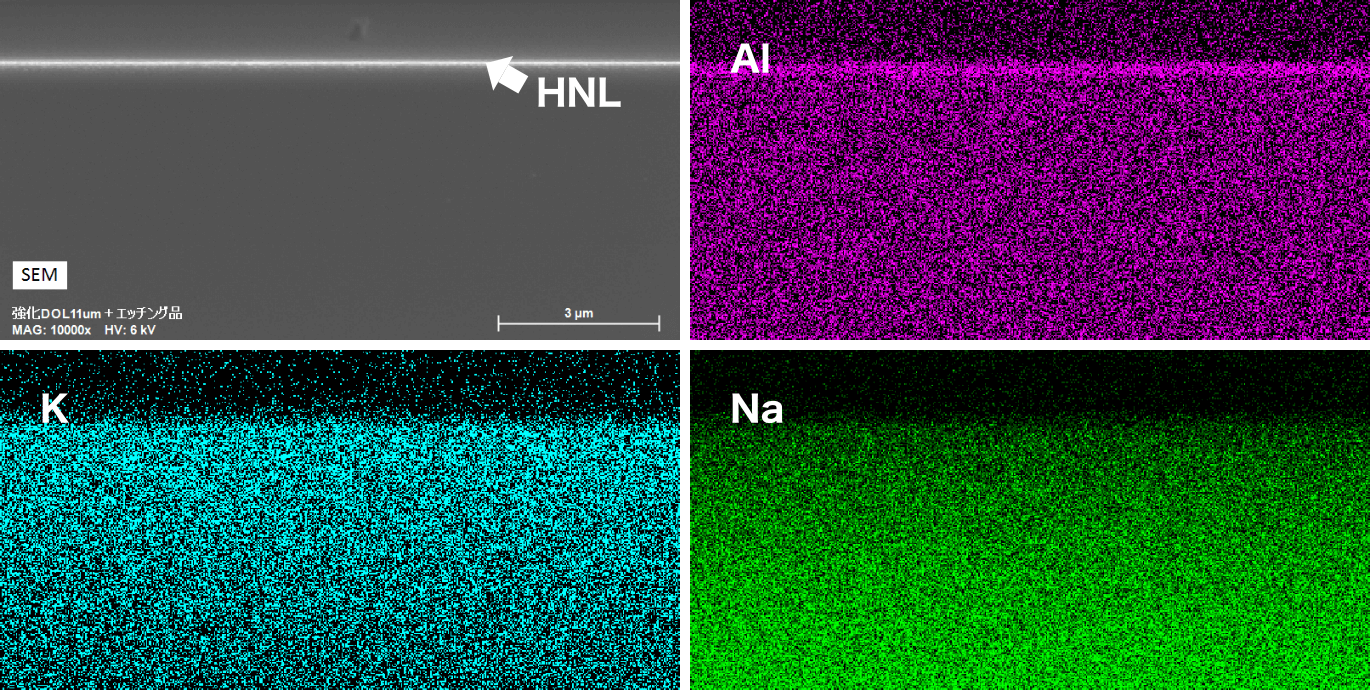

Cross-sectional SEM Image of HNL Glass and EDAX Analysis Results of the Layer Below HNL

EDX Images (Porous Layer)

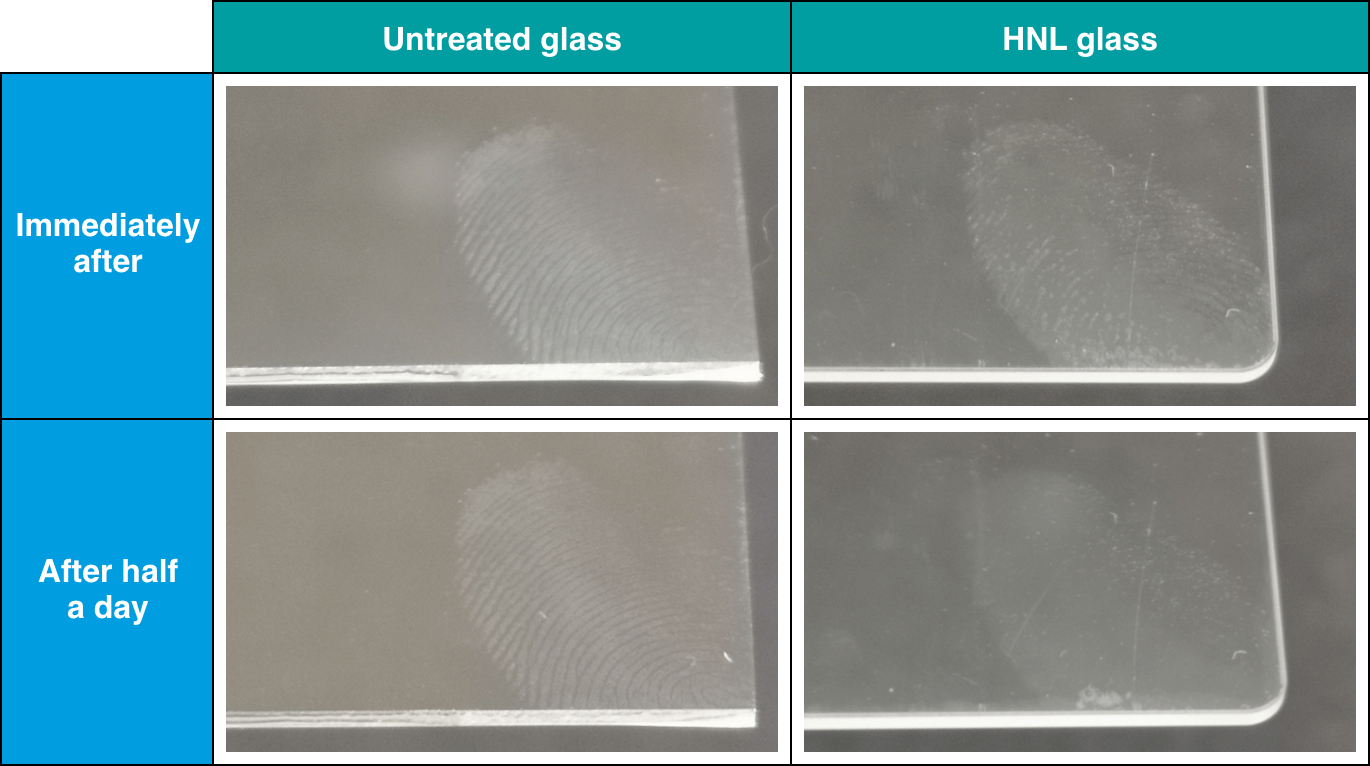

Anti-soiling Effect

A phenomenon was observed where adhered fingerprint marks blurred over time.

Changes After Half a Day Following Fingerprint Deposition on Untreated Glass and HNL Glass

Application example

The basic functionalities of this technology are as follows:

・High broadband transmittance / low reflectivity of visible light

・Hydrophilicity

・Anti-fouling function

Utilizing these functionalities, applications in fields such as displays, signage, solar panels, and light extraction components are being considered.

Additionally, applications and developments in fields utilizing the porous layer, such as sensors, are also under consideration.

Touch panel

Solar panel

Digital signage

Glossary

Hierarchical and Gradient Structures

These terms refer to structures where the state (structure) changes gradually. The hierarchical nanoporous layer (HNL) is a nanoporous structure formed with pores at the tens of nanometer level that gradually decrease in size from the glass surface side toward the interior of the glass.

HNL Glass

It is Hierarchy Nanoporous Layer Glass.

GNL Glass

It is Graded Nanoporous Layer Glass.

Porous Material

Materials consisting of innumerable pores are called porous materials. Materials where individual pores are isolated are called closed-cell porous materials (independent foam bodies), while those where the pores are connected are called open-cell porous materials (continuous foam bodies), etc. HNL glass is glass in which a layer consisting of open-cell porous material is formed on the glass surface, and moreover, the sizes of these individual pores are formed to gradually decrease from the glass surface layer toward the interior of the glass, possessing a continuous pore layer.

Chemical Strengthening

A strengthening method where the glass is immersed in high-temperature molten salt (KNO₃), and by ion exchange between the small ionic radius sodium ions in the glass and the large ionic radius potassium ions in the molten salt, a compressive stress layer is formed on the glass surface layer.

Glass for Chemical Strengthening

Glass that contains a high amount of sodium ions, etc., in its composition. A known method of chemical strengthening is to exchange the potassium ions in potassium nitrate salt with the sodium ions in the glass to form a compressive stress layer (CS) on the glass surface layer. Types of glass such as soda-lime glass and aluminosilicate glass are used as glass for chemical strengthening.

Ion Exchange

Refers to the exchange (movement) of ions in the glass with ions in the molten salt.

CS : Compressive stress (surface compressive stress)

A numerical value that indicates the magnitude of compressive stress that appears on the glass surface. The larger the number, the more it prevents the development of microcracks on the glass surface that cause breakage.

DOL : Depth of Layer

A value that indicates the depth of ion exchange from the glass surface due to chemical strengthening.

Central Tensile Stress (CT)

In chemically strengthened glass, a compressive stress layer is formed on the glass surface, and inside the glass, tensile stress (Center Tension) occurs to balance this compressive stress.

Weak Basicity, Weak Alkalinity

Refers to the properties of an aqueous solution. Weakly basic (alkaline) solutions are liquids with a pH greater than 8 and up to 11. The stronger the alkalinity (or acidity), the higher the glass's ability to corrode.

Etching Method

A technique that utilizes the corrosiveness of acids, alkalis, ions, etc., to process the surfaces of metals, glass, semiconductors, and other materials.

ROR (Ring On Ring) Test

One method for evaluating the surface strength of tempered glass. It is a failure evaluation method where glass is clamped between a large-diameter ring and a small-diameter ring and pressure is applied.

Hydrophilicity

On surfaces where the contact angle of water droplets is within 10° or less, water droplets spread out on the glass surface.

Water Repellency

On surfaces where the contact angle of water droplets is 90° or more, water droplets roll easily on the glass surface.

Polishing

A process of polishing the glass surface using cerium particles with urethane or suede pads.

Loading

Refers to retaining nanoparticles and the like in the pores of the nanoporous layer, whereby new functions are manifested depending on the particles loaded.

Visible Light Transmittance

A numerical value indicating the percentage of visible light (light visible to humans: 380nm to 780nm) that passes through the glass relative to the incident light.

HAZE

An index representing the degree of cloudiness or light scattering of a transparent material, expressed as the ratio of the diffuse transmittance (DIF) excluding the parallel component to the total light transmittance (T.T) which includes the parallel component P.T and all diffuse components.

FAQ

Is it possible to send a sample?

It's possible. Please contact us for specifications such as dimensions and thickness.

Contact usCan you form it with our own glass?

The ease of formation varies depending on the composition of the glass, but we can consider it if you provide it to us.

Contact usWhat is the product size?

Currently, the maximum size is 300mm x 300mm.

It is technically possible to handle even larger sizes.

To what extent can you handle the thickness of the glass?

There are no particular restrictions in terms of formation technology, but we handle up to a thickness of 2mm.

How is the thickness measured?

Since it is a gradient film without interfaces, it's difficult to measure with optical measuring instruments, so we currently observe it using SEM images.

We are also considering estimating the thickness from transmittance data.

What is the refractive index?

Due to the gradient nature of the film, the refractive index gradually changes with depth.

An approximate value can be obtained from the average refractive index of the glass substrate and air.

Can you do various coatings?

It is also possible to support coating on HNP glass. Please contact us for details.

Contact usWhat is the price and delivery time?

Please contact us for details.

Contact us