Automatic optical inspection

Original optical part contribute to improve efficiency and visual precision in advanced fields.

On manufacturing production lines, optical inspection machines confirm surface defects, such as foreign objects or dirt, scratches, burrs, chips, and deformations. These inspection systems determine whether products are acceptable or not. Their importance is increasing for products and parts where cost reduction via improved productivity (less labor and manpower) and high-precision inspection are in demand.

Specifically, demand for it is expanding in inspection of advanced products, such as semiconductors, electronic/electrical parts, food, drugs, cosmetics, and lithium-ion batteries for environmentally-friendly vehicles (EV). There are more needs for higher quality and higher resolution sensor cameras. NSG is developing optical parts that contribute to improved performance of automatic optical inspection machines with their own glass composition technology and optical design technology.

Achieving simpler, smaller, and more space-saving automatic optical inspector

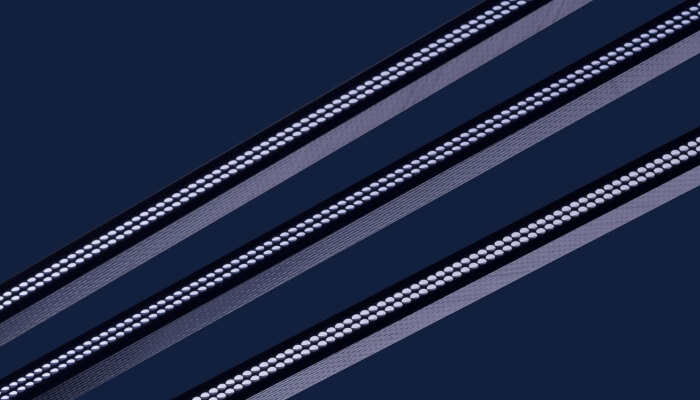

By applying SELFOC® Lens Array to the part for image reading in automatic optical inspection machine, optical path can be designed short while maintaining images with high quality and brightness. With simple CIS module optical design combined with a line-shaped lighting and sensors, inspection machines are being miniaturized.

With rapid expansion of demand in industrial inspection machines, SELFOC® Lens Array "SLA5DG" is newly developed. This allows for a compact optical design while improving long-depth feature of machine vision.