Low-dielectric glass flakes

Low-dielectric glass flakes are scaly amorphous glass fillers that reduce transmission loss in high-frequency molded products using NSG's proprietary glass composition and processing technology.

Product summary

Low-dielectric glass flakes are high-performance glass fillers (amorphous) with significantly lower dielectric constant/dielectric tangent than conventional glass fillers.

It is effective in reducing transmission loss, improving coefficient of thermal expansion (CTE), and suppressing warpage and waviness, which are required for next-generation semiconductor materials and high-frequency compatible materials. It is expected to improve performance by reducing energy consumption in semiconductor components, increasing the number of layers in package substrates, increasing their size, and suppressing disconnections and cracks in copper wiring.

Low-dielectric glass flakes

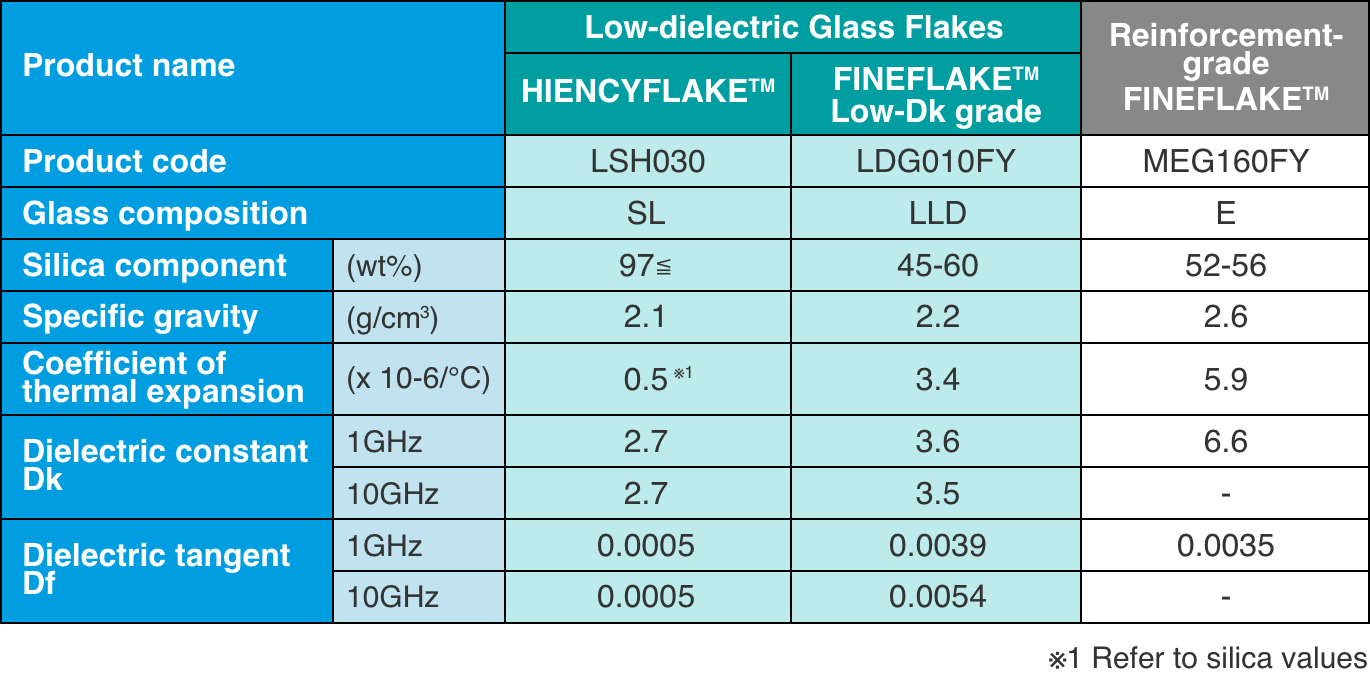

There are two types of low-dielectric glass flakes: FINEFLAKE (LLD glass) and HIENCYFLAKE (SL glass).

FINEFLAKE utilizes a specially formulated LLD glass composition to achieve an excellent low dielectric constant.

HIENCYFLAKE, on the other hand, is an amorphous glass flake containing more than 97% silica and is manufactured using NSG’s proprietary processing technology.

Among platelet-shaped glass fillers, it offers exceptionally low dielectric constant and dielectric loss, delivering one of the highest levels of dielectric performance available.

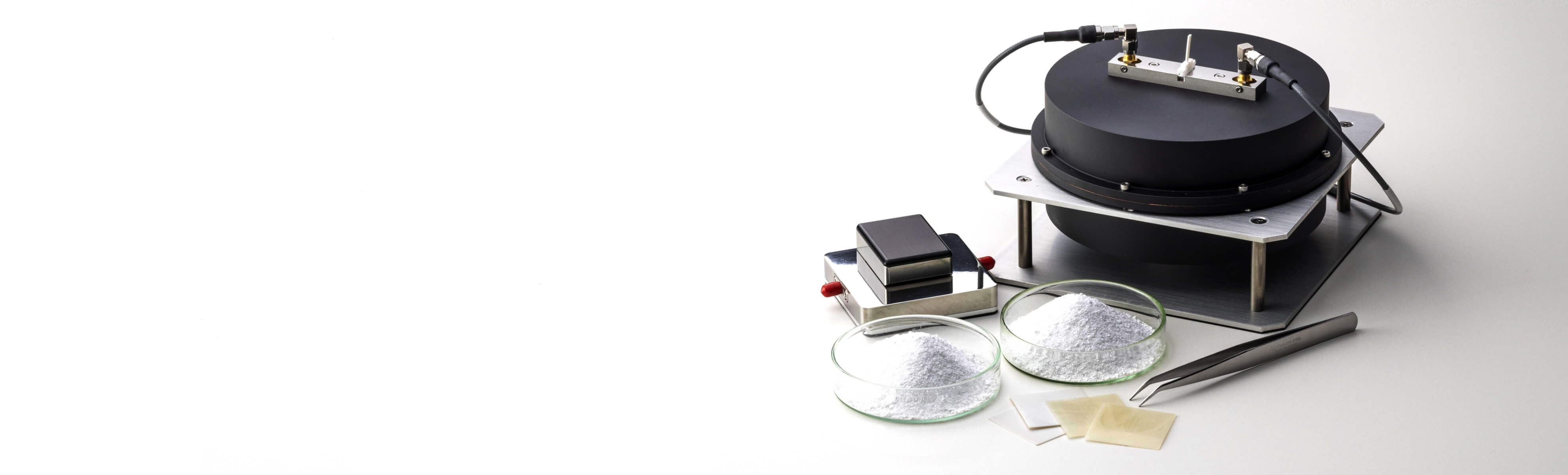

Characteristics of low-dielectric glass flakes

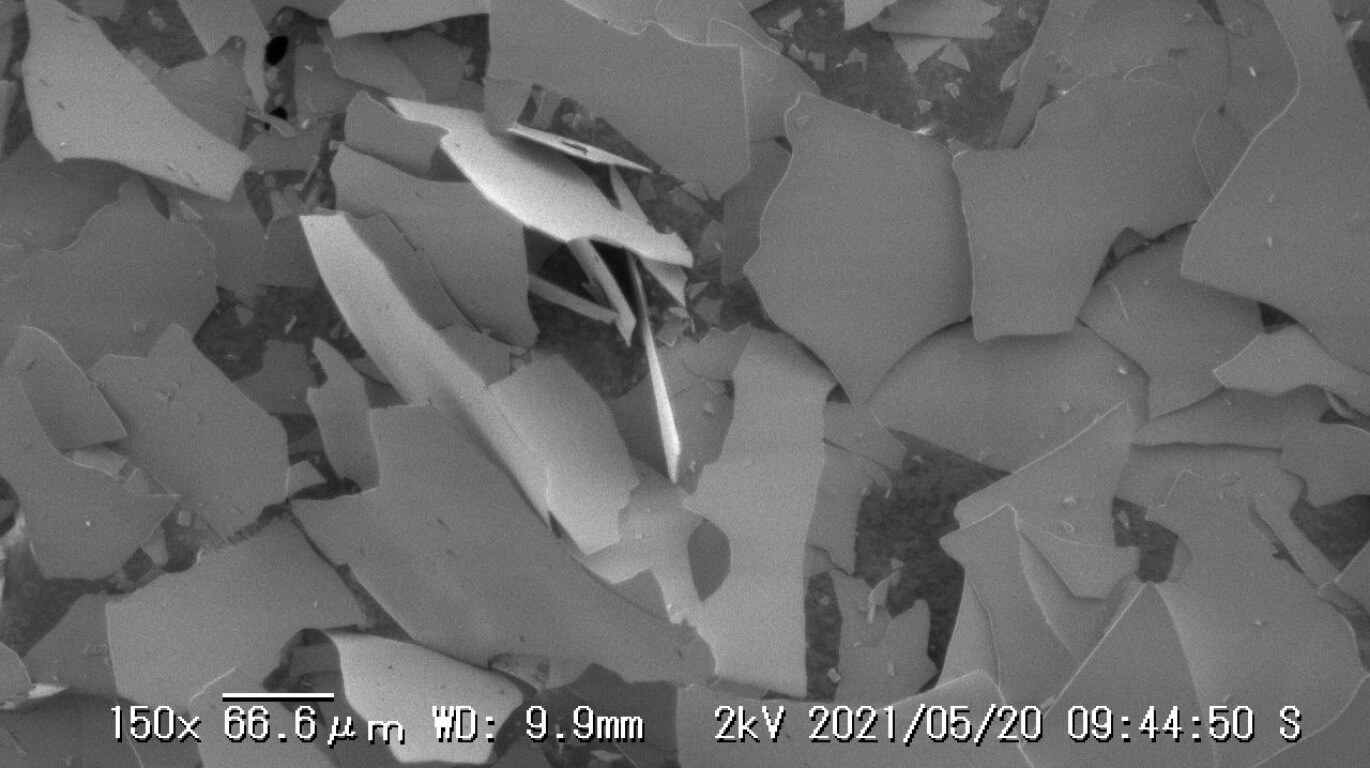

LLD glass flake (mean thickness :0.7 µm, mean particle size :160 µm) SEM image

LLD glass flake (mean thickness :0.7 µm, mean particle size :160 µm)

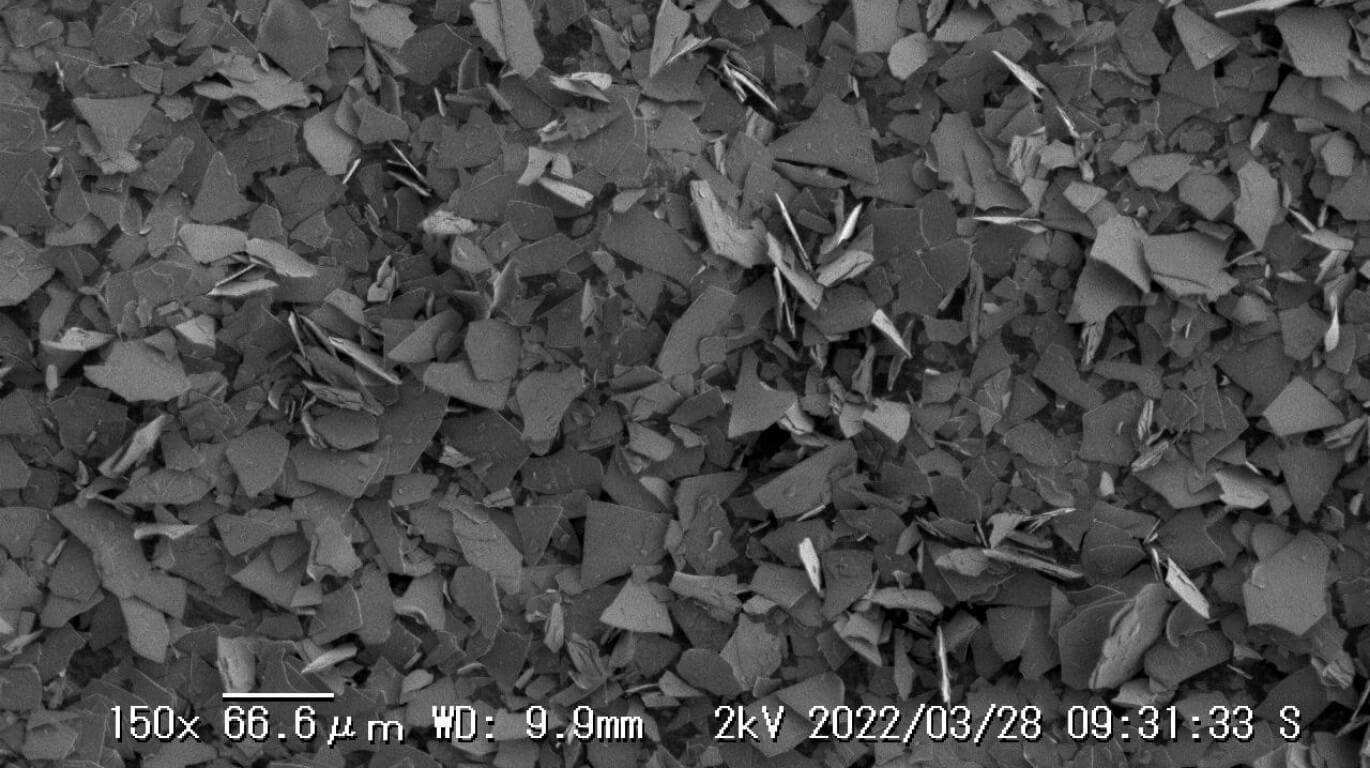

SL glass flake (mean thickness :0.8 µm, mean particle size :30 µm) SEM image

SL glass flake (mean thickness :0.8 µm, mean particle size :30 µm)

Features of low-dielectric glass flakes

-Dielectric Properties

A glass composition containing more than 97% SiO₂ has been developed to deliver excellent low-dielectric performance.

-Dimensional Stability and Warpage Improvement

Uniform dispersion of glass flakes within the resin enhances dimensional stability and reduces warpage in resin components.

-Improved Modulus, Fracture Strength, and Toughness

By optimizing the aspect ratio of the glass flakes (particle diameter ÷ thickness) and their adhesion to the resin, the elastic modulus, fracture strength, and toughness of the composite material can be significantly improved.

-Adjustment of Coefficient of Thermal Expansion (CTE)

The CTE in the X-, Y-, and Z-directions can be precisely controlled by adjusting the loading level of the glass flakes.

-Ionic Impurities

A glass composition with low ionic impurity levels has been developed to ensure high material reliability.

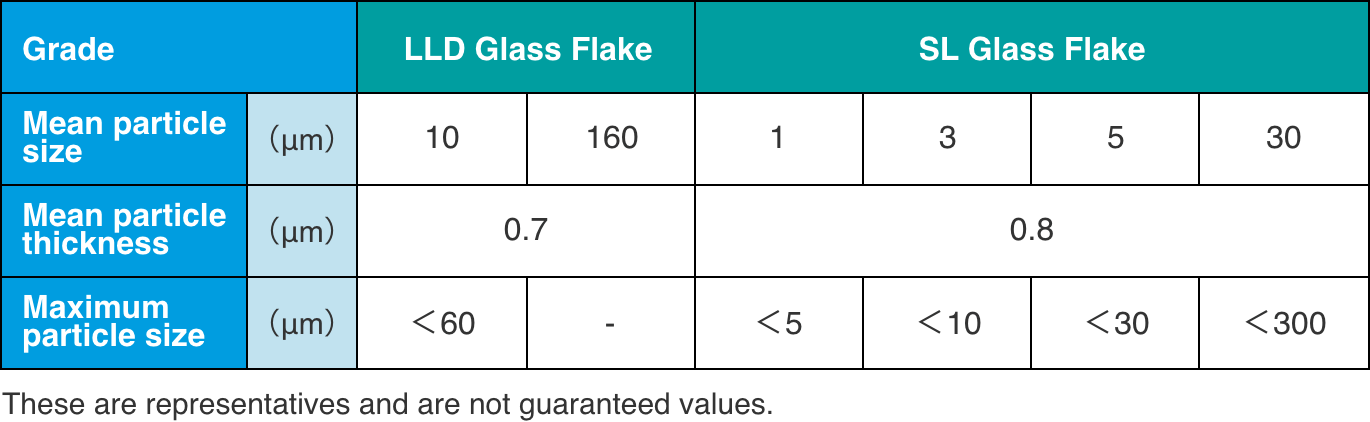

Low-dielectric glass flake lineup

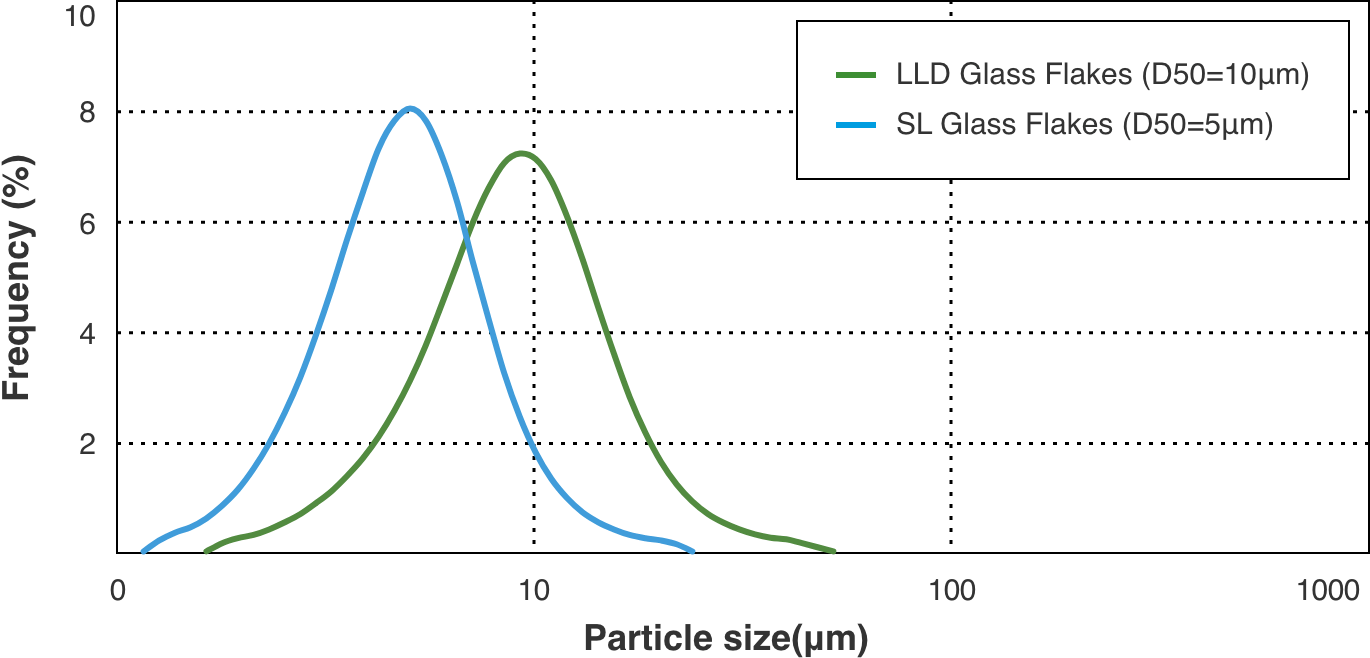

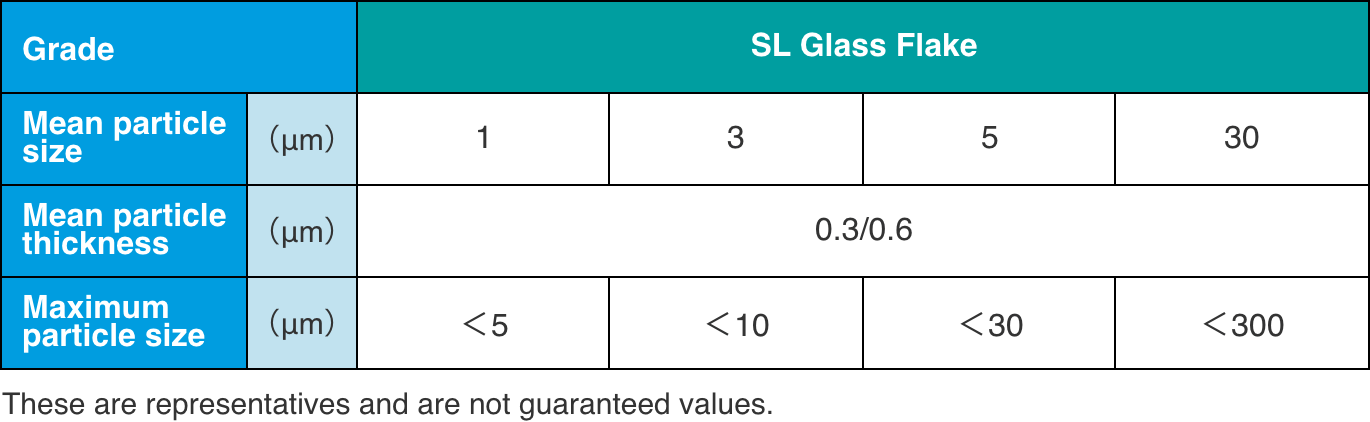

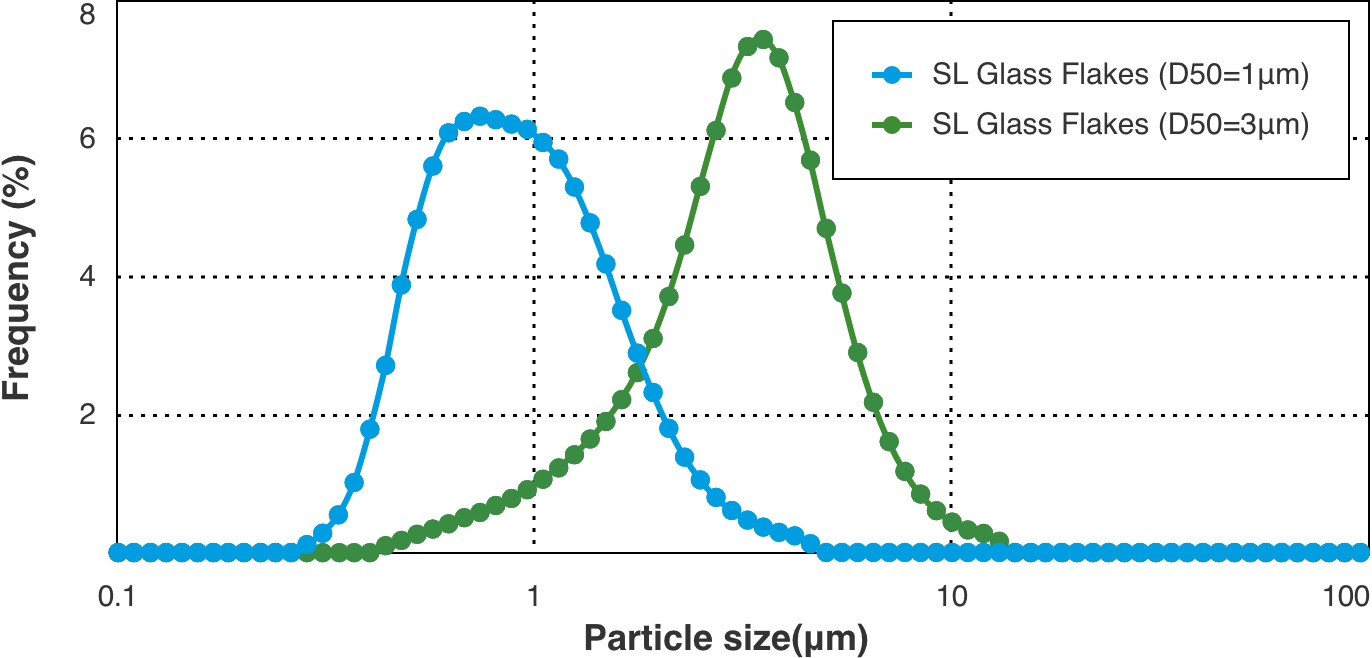

Particle size: Samples with mean particle sizes of 10 and 160 µm for LLD glass flakes and 5 and 30 µm for SL glass flakes are available as standard material. Using NSG's proprietary milling technology, the samples are adjusted to have sharp particle size distribution that suppresses maximum particle diameter.

Surface treatment: Suitable surface treatments are available for resins and applications.

Low-dielectric glass flake particle size

Low-dielectric glass flake particle size distribution

Lowering dielectric constant and lower dissipation factor in molded resin products

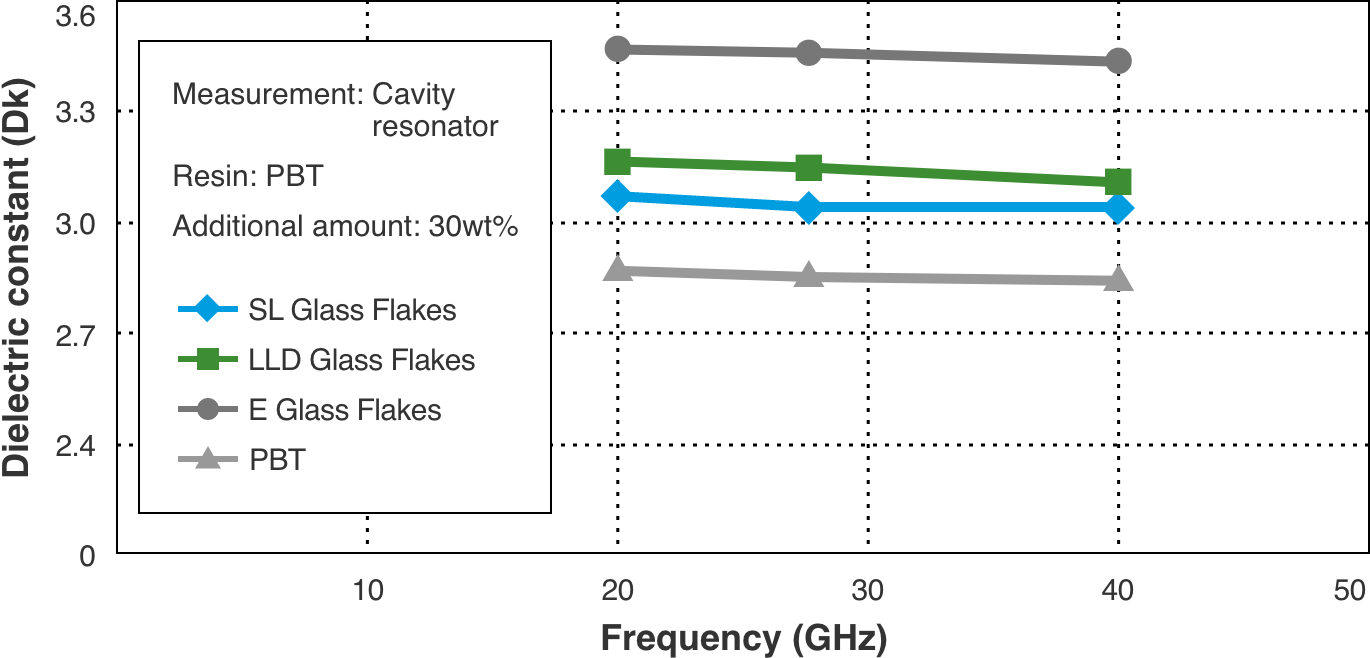

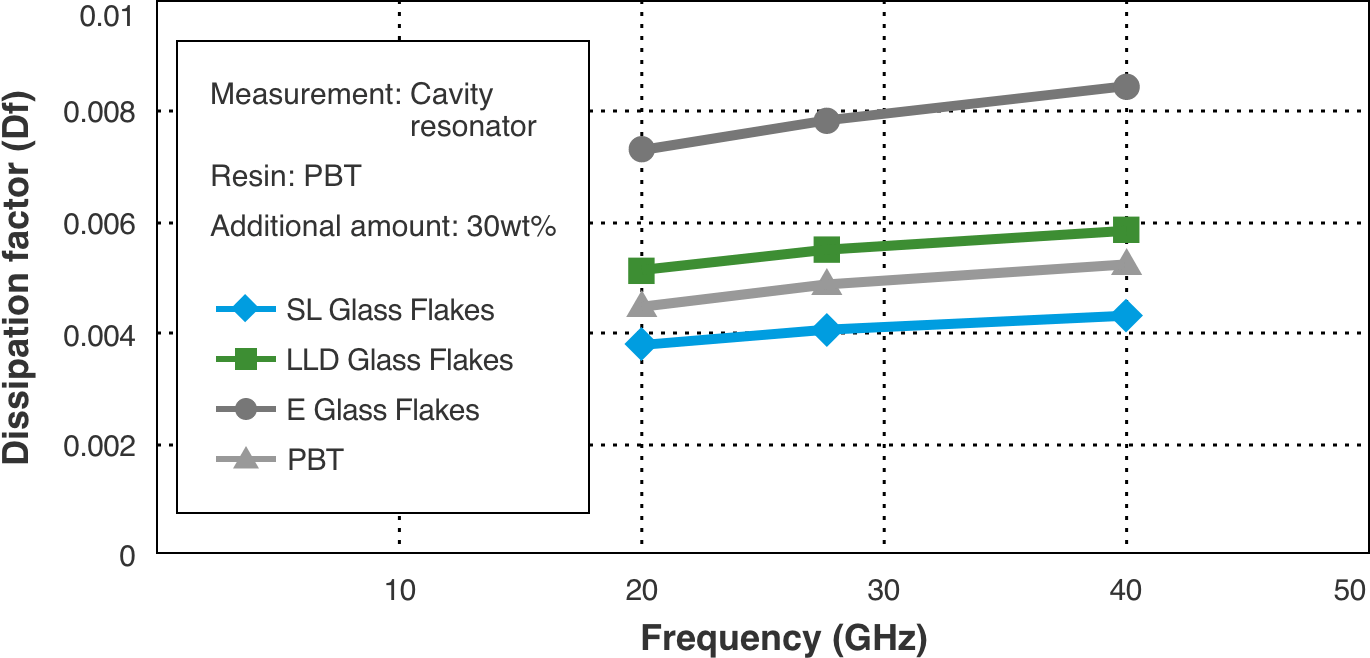

When low-dielectric glass flakes are mixed with PBT resin, the dielectric constant and dissipation factor of molded resin products can be lowered at the high frequency range of 20–40 GHz.

Dielectric constant of molded resin products with low-dielectric glass flake

Dissipation factor of molded resin products with low-dielectric glass flake

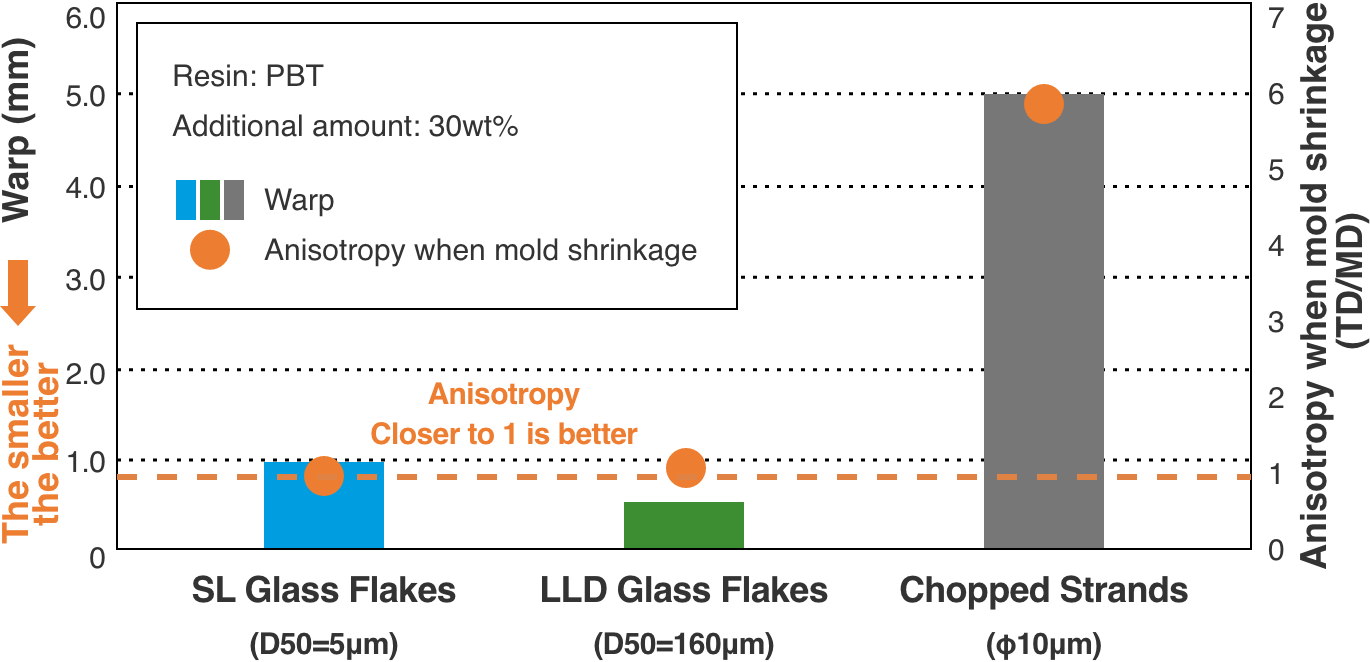

Dimensional stability and low coefficient of thermal expansion

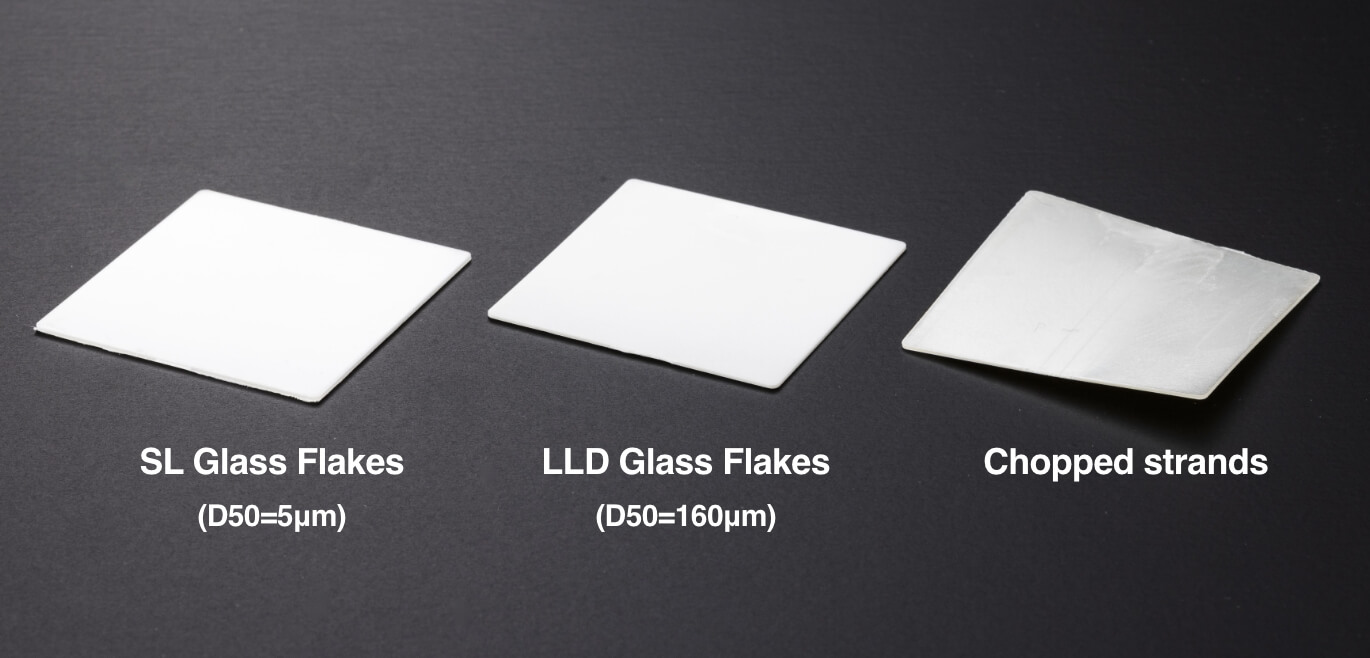

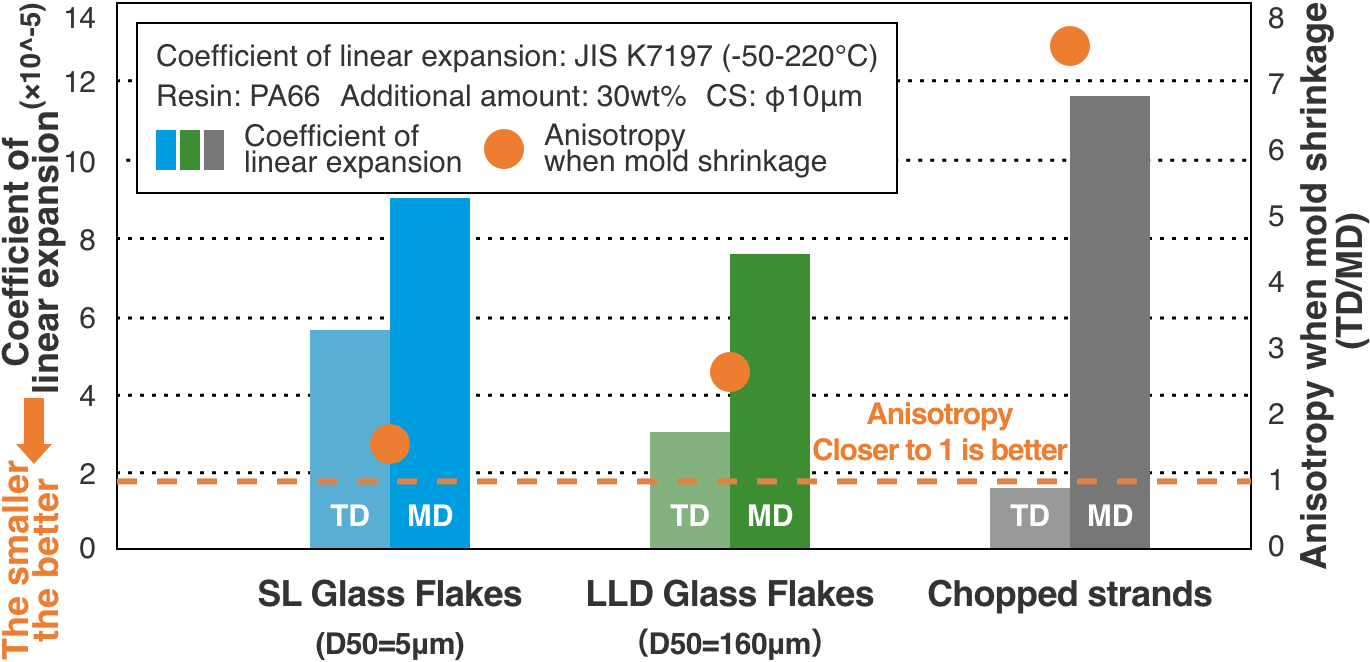

LLD glass flakes and SL glass flakes are scale-shaped glass additives having a high aspect ratio (thickness-to-particle average diameter ratio) and submicron thickness. When compared to the chopped strands of fibrous anisotropic additives, thin glass flakes are especially and naturally effective in isotropic additive alignment used in the plastic compounds resulting in significantly reduced or eliminated warpage (differential shrinkage) of molded resin finished products. Additionally, NSG glass flakes are able to suppress the overall plastic part shrinkage rate. Because low-dielectric glass flakes have a very low coefficient of thermal expansion, glass flakes themselves can realize high dimensional stability in relation to temperature changes at the time of plastic component processing.

Warpage of molded products containing low-dielectric flakes and anisotropy at the time of mold shrinkage (TD/MD)

Comparison of warpage in molded resin products (0.5 mm thickness)

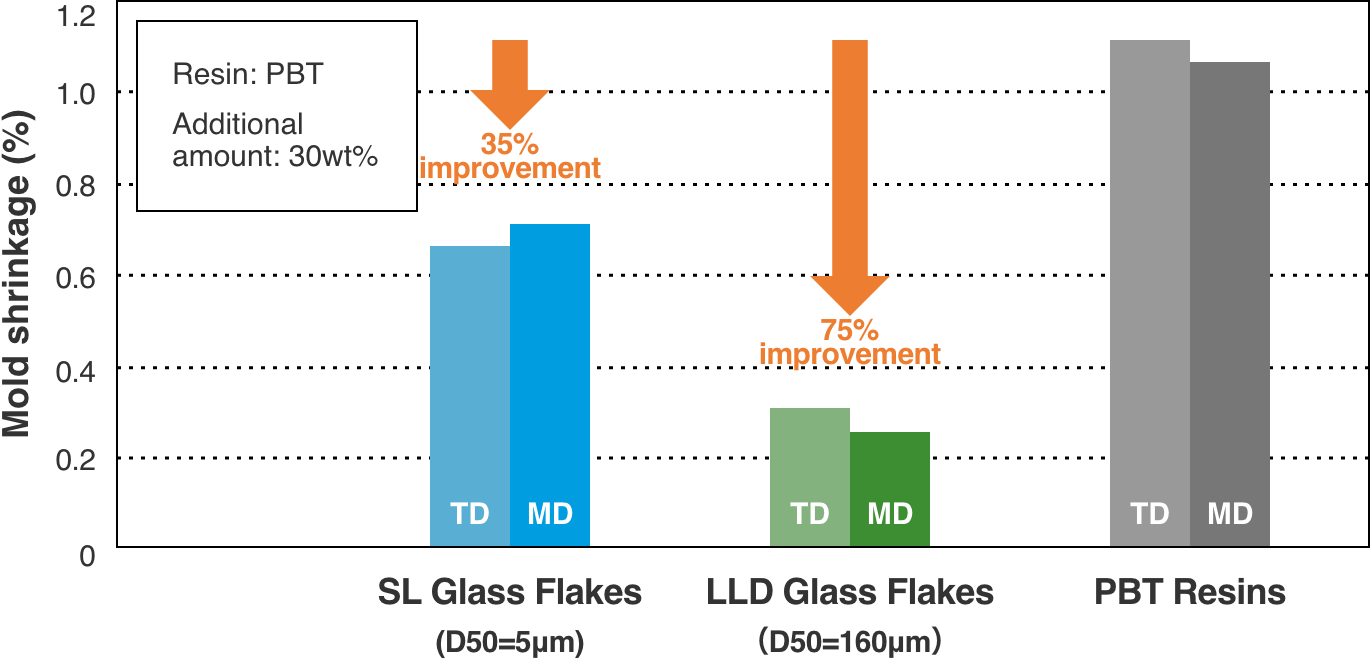

Rate of mold shrinkage of molded resin products containing low-dielectric glass flakes

Thermal expansion coefficient of molded resin products containing low-dielectric glass flakes

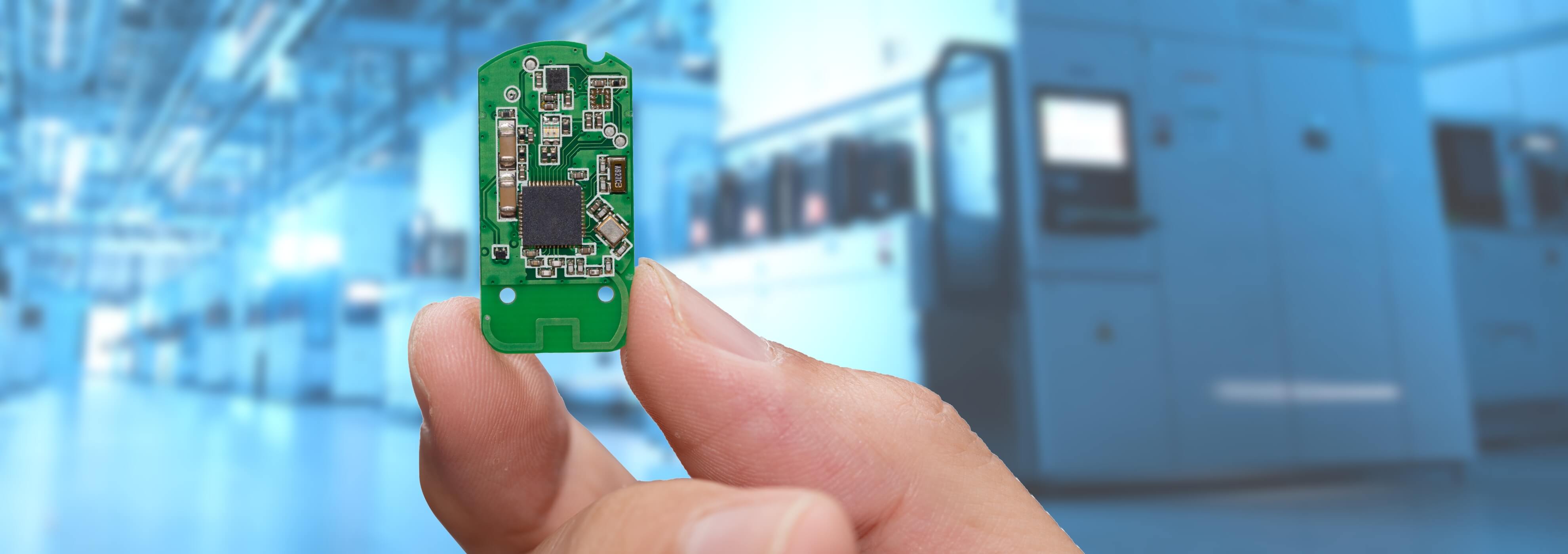

Applications of low-dielectric glass flakes

Widely applicable to molded resin products for high-frequency telecommunications

・Housings, radomes, connectors, antennas, etc., for products and components with high-frequency communications technology

・Rigid and flexible print circuit boards used for high-frequency components in base stations, smartphones, PCs and the like

Base station antenna (PCBs, antenna, radomes)

Smartphones (PCBs, connectors, housings)

Millimeter wave radar (PCBs, connectors, radomes)

Print circuit boards (copper clad laminates, solder resists, interlayer insulation)

Development product lineup

At NSG, we are developing even thinner glass fillers by leveraging the glass molding technology we have cultivated over the years.

Development product particle size

Development product particle size distribution

Glossary

Dielectric constant(Dk)

Rate of polarization of a dielectric in an electric field.

Dissipation factor(Df)

Numerical value expressing the degree of electrical energy loss within the dielectric.

Coefficient of thermal expansion (CTE)

Expansion rate of material against increasing temperature (expressed as ppm).

Glass Composition

-E-glass:A glass composition with excellent electrical insulation properties that contains virtually no alkali components.

-LLD glass:An original NSG glass composition engineered to achieve a reduced dielectric constant.

-SL glass:An amorphous silica-based glass composition with a high silica content, designed to lower both the dielectric constant and dielectric loss tangent.

Aspect ratio

Number obtained from dividing particle size by thickness of glass flake, indicating rate of particle size/thickness.

FAQ

Is it possible to receive sample?

Yes. Please inquire for details.

Contact usIs surface treatment available?

Yes. Suitable treatment can be selected in accordance with the resin and use.

Is it possible to change the particle size?

Yes. Please inquire for details.

Contact usIs it possible to change the thickness?

Firstly, please consider standard thickness products (1 µm or less) that realize excellent dimensional stability and strength characteristics.

What is the price and delivery time?

Please inquire for details.

Contact usFlake shape glass filler products list

NSG offers a variety of flake shape (scale-shaped) glass fillers to suit different granular sizes and applications.

For details on each product, please see the links in the table below.

| Products | Mean particle thickness [um] | Mean particle size [um] | Product use |

| GLASFLAKE® | 2~5 | 15~600 | Anticorrosion / corrosion resistant paint |

| FLEKA® | 5 | 160~600 | High-performance resins |

| FINEFLAKE™ | 0.7 | 160 | High-performance resins |

| DURAFLAKE® | 0.35 | 140 | High-performance resins |

| Low-dielectric glass flakes | 0.3~0.8 | 1~160 | Printed circuit boards / Interlayer insulation |