Rubber

Rubber products with NSG material for high-efficiency transmission systems have changed the way automotive engines are designed.

With miniaturization of mobility and automation of industrial machines, lighter, more efficient transmission systems are desired. To achieve high-precision movements under high-load conditions, a transmission system that uses rubber products is being developed.

NSG is utilizing production technology for rubber materials, first used in the automotive industry, and continues to develop and provide key materials for improved performance and reliability of transmission systems, contributing to the wider use of rubber materials.

Adoption to drive system for industrial robots

Recent innovations have increased the demand for industrial robots. A new technological trend, "Industry 4.0", has led to automation in various industries, and increasing investment in robots is anticipated.

To achieve automation of manufacturing processes and higher productivity, faster and more precise movements are needed for robots. However, with the existing drive systems that use rubber timing belts, movements accompanied with rapid acceleration and deceleration and positioning accuracy could not be achieved.

NSG developed a new Glass Cord that combines highly-elastic carbon fiber and their own textile processing technology, allowing for improved performance of timing belt for robots. Furthermore, this development allowed for faster and more precise movements. As a solution for automation and higher speed in industry, increased demand for Glass Cord is anticipated.

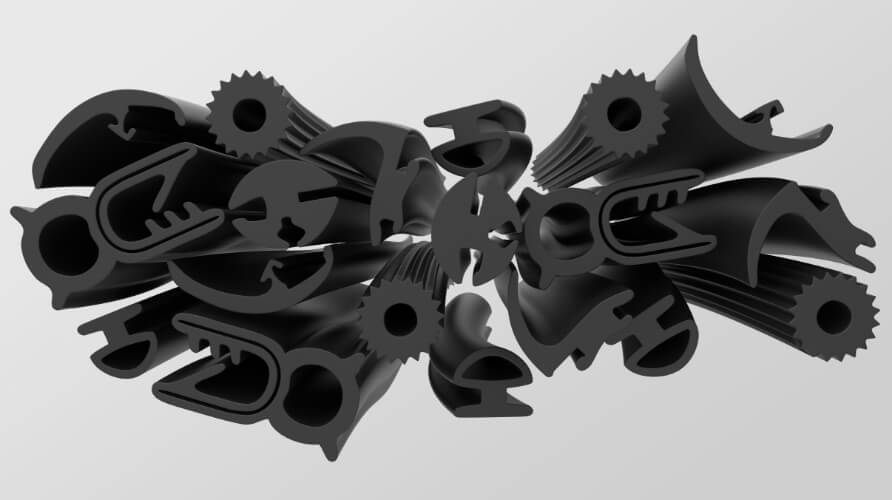

Improved durability/productivity of extruded rubber molded products for automotive applications

Sealing materials and weather strips made of extruded rubber moldings are used to fill gaps between automobile doors and car bodies. These components have the problem of bending and deformation due to pressure contact with the door over a long period of time, as well as the issue of low productivity during installation on the car due to differences in the dimensions of the rubber molded part.

To overcome this problem, Glass Cords with high tensile strength and dimensional stability are used in molded rubber products to prevent viscous deformation and shrinkage during long-term use of the components and improve installation and productivity.

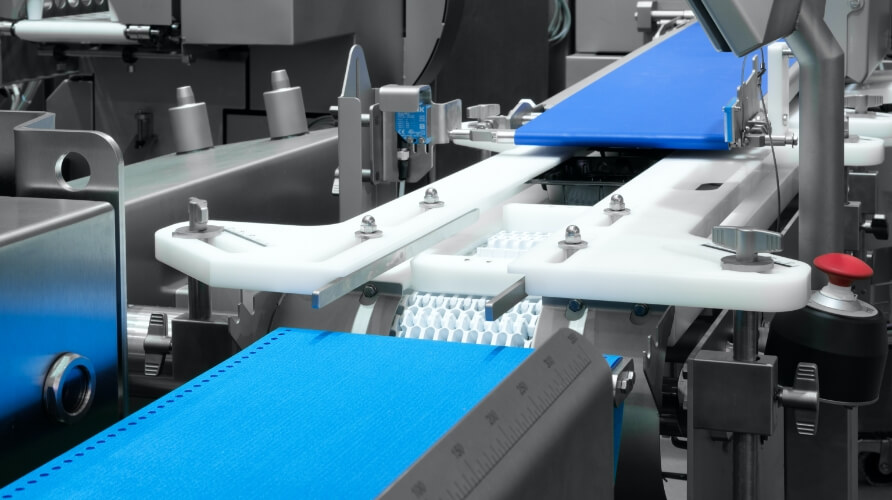

Examination to drive system for transport facilities

Capital investment in smart factories is increasing. To achieve optimum production, machines and facilities that are connected via a network must be highly efficient and trouble free. On the transfer line of electronic devices, medical industry, and food, there were concerns for defects caused by static electricity.

To solve this issue, timing belts made of rubber or resin without metallic material are actively being examined and employed to drive transfer lines. As the ideal reinforcing material, light, and without magneticity and corrosion risk, Glass Cord designed by NSG, supports stable and efficient production in factories.

Efforts to increase the functionality of rubber hose

In the field of lightweight, flexible, high-performance rubber hoses, the conditions of use are becoming harsher, while demand for longer service life is also increasing. Similarly, high environment resistance and durability are required for the components added to rubber hoses.

Glass Cord has excellent dimensional stability, high elasticity, high flexibility, weather resistance, and adhesiveness to rubber. In particular, the high adhesive strength of the Glass Cords is expected to improve the strength, and reduce delamination of laminated sections of the rubber hoses and damage during use.

Application to rear-wheel drive for motorcycles

Driven by emission regulations, SDGs and an increase in demand during the COVID-19 Pandemic, the market for electric bikes and scooters has rapidly increased. The market wants electric bikes and scooters with even higher performance. Specifically, for rear-wheel drive motorcycles, a power transmission system that is lighter, quieter, with higher torque and efficiency is desired. Instead of a gear and resin belt, maintenance-free rubber timing belts are being examined.

The new Glass Cord developed by NSG is light and uses highly elastic carbon fiber. It is expected to be well received in the market as a reinforcing material that is well suited for rear-drive motorcycles.

Efforts to lengthen tire life

Tires are installed in not only automobiles but also motorcycles, bicycles, kickboards, and various other vehicles.

Using reinforcements in tires improves their durability, reduces deterioration and wear, and extends their service life.

The use of Glass Cord extends tread life by improving heat dispersion and increasing tensile strength.

Furthermore, using RICS also prevents cracking and chipping of the tread surface.

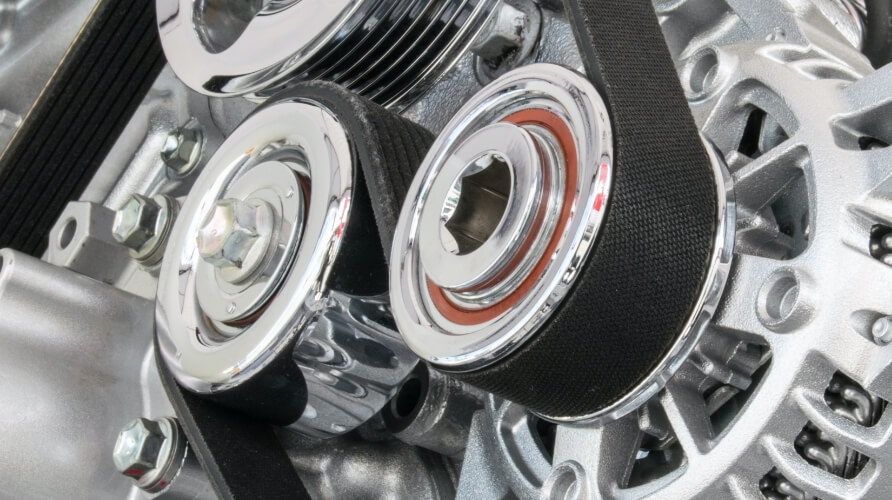

Expansion to rubber V-belt for accessory drive of mild hybrid vehicles

Mild hybrids that use auxiliary starter/generators as drive motors are being adopted by automobile companies worldwide as a simple and compact electric device capable of improving fuel efficiency by 10 to 20%. Starter/generators in mild hybrid vehicles experience higher loads than usual so the rubber V-belts must have high power transmission performance and durability.

To answer this need, NSG developed a new Glass Cord as a reinforcing material for rubber V-belt by combining aramid fiber and their own adhesion technology. The newly developed Glass Cord is a further example of rubber products improving the fuel efficiency of automobiles.

To improve the durability of woven cloth/mats

In our daily life, we use several rubber and resin product in the form of cloths and mats that comprise fibers.

Durability is crucial for these products because they are difficult to replace due to spatiotemporal constraints.

Glass Cord offers excellent dimensional stability, high elasticity, flexibility, weather resistance, and adhesiveness to rubber and resin.

Glass Cord can contribute to the improvement of the durability of products made with woven cloth and mats by taking advantage of these properties.

In particular, high adhesive strength is expected to reduce delamination in laminated areas and damage during use.

Other Applications

Sporting equipment such as gloves, shoes, and fins; cushioning materials for vibration control and soundproofing; filament materials for 3D printers; rubber products for outdoor use (rubber mats, rubber tiles, rubber boots, etc.); rubber rollers; rubber crawlers; rubber pipes and piping; rubber packing; rubber sealing; and nichrome wire. Our products contribute to various industrial fields as reinforcing materials.