High-performance resin

NSG add new value to the world with materials that miniaturize, strengthen, and stabilize resin parts.

Use of engineered plastics is rapidly expanding: housings for electrical components in automobiles, connectors for small electronic devices such as smartphones, FRP as diverse exterior material, and so on.

NSG is developing functional materials that improve the performance of resin products beyond their current levels.

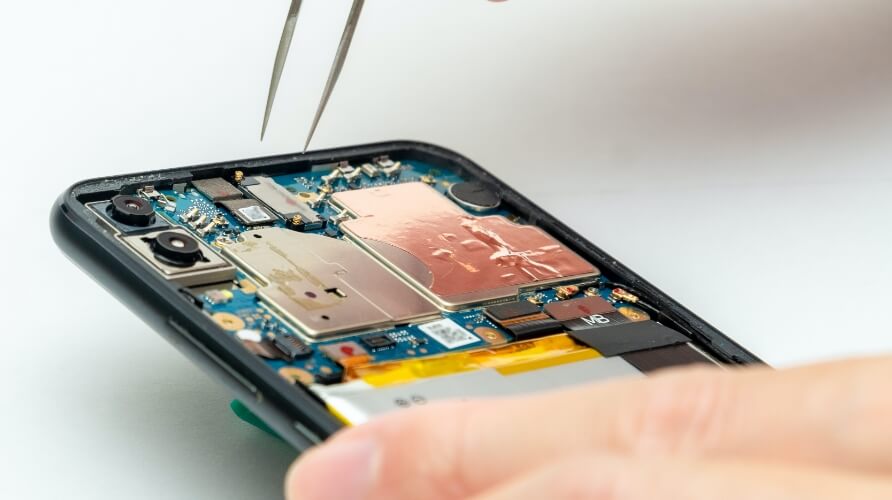

Improved dimensional stability for ultra-small devices

With thinner and smaller mobile devices, electronic connectors also need to be thinner (1 mm or less). It was difficult to prevent such small resin parts from warping, but NSG's ultra-thin glass product, FINEFLAKE™/DURAFLAKE™, can be used as an additive in engineered plastic parts, achieving superior dimensional stability.

NSG continues the materials development programs in order to support the expansion of wireless communications with novel innovations.

-

![Thin engineered plastics connector]()

Thin engineered plastics connector

Improved thermal resistance of thermoplasticpolymers for automobiles

Because of its light weight and ease of forming, engineered thermoplastic molded products are widely used for automobiles. Especially in recent years, there are increasing applications for reduced weight of automobiles in order to improve fuel efficiency and reduce CO2 emissions.

For the engine compartment and for parts near the power module where heat-resistance is desired, high-performance thermoplastic molded products are being employed.

As a reinforcing additive with good balance between precision, strength, and heat resistance, more customers are using FLEKA® to achieve the industry's new requirements.

-

![Resin parts for automobiles]()

Resin parts for automobiles

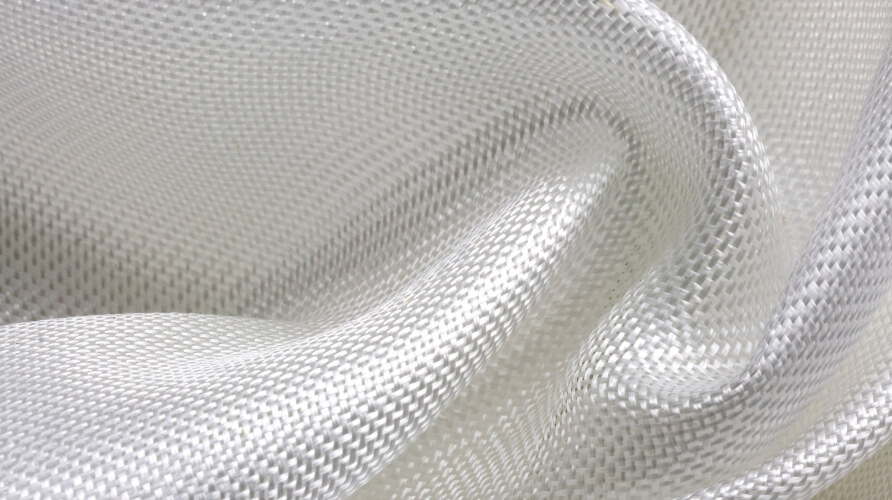

Expanding potential for FRP/FRTP applications

FRP/FRTP is garnering attention in the market as a substitue for metal in order to reduce weight.

As a potential reinforcement material, carbon fiber and aramid fiber are being considered, but neither material satisfies all requirements : cost, appearance, electrical insulation, radio transmission, durability and mechanical strength.

NSG has developed a new reinforcing fiber, MAGNAVI™ . It is a high-performance engineerd material having superior strength, elastic modulus, appearance, electrical insulation, and radio transmission characteristics, now commercialized for the marketplace. NSG is working to expanding its sales to support application of FRP/FRTP into the 5G wireless communications infrastructure.

-

![Reinforcing fiber]()

Reinforcing fiber

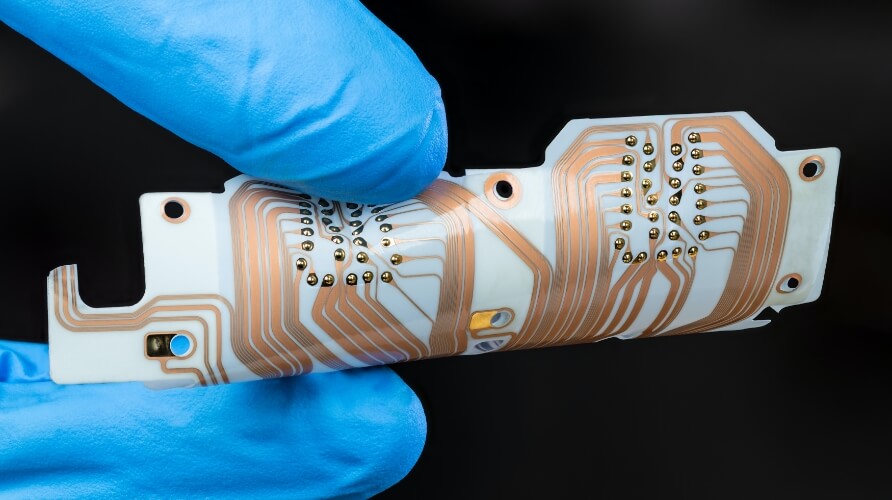

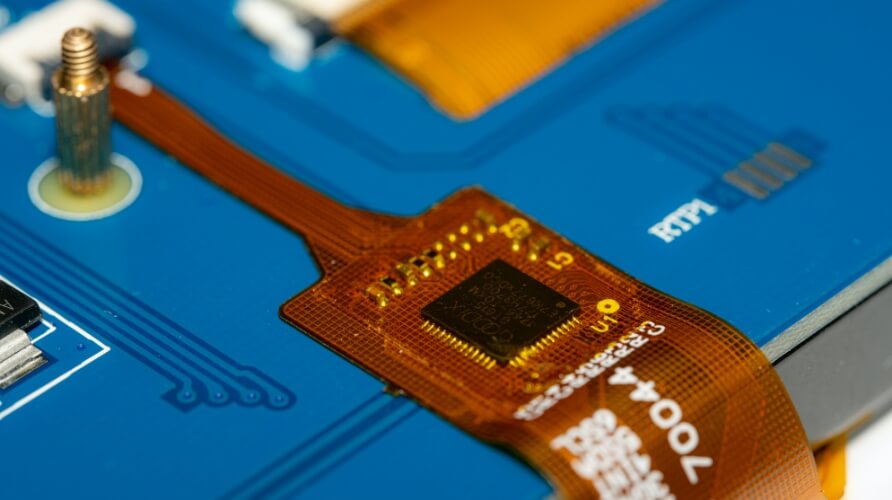

Achieving a reduction in transmission loss and compactness in printed circuit boards for high-frequency wireless communications

With the increase in data communication volume, the use of wireless communication in the high-frequency field that can enable high-speed and high-capacity communications is growing. Transmission loss increases with higher frequencies. Materials with excellent dielectric properties and low transmission loss are required for electrical and electronic components that process these high frequencies. High-frequency printed circuit boards need resin materials having a combined low dielectric constant + low dissipation factor glass additive in order to suppress transmission loss. Additionally, it is a requirement that the resin materials have low heat expansion and dimensional precision to support the needs for smaller and thinner printed boards. The low-dielectric glass flakes developed by NSG are new glass additives that simultaneously achieve low dielectric constant, low dissipation factor, low thermal expansion and exceptional dimensional stability. These glass-based additives are expected to contribute to printed circuit board formulations used for high-frequency wireless communications.

-

![Flexible Printed Circuits]()

Flexible Printed Circuits

-

![Flexible Printed Circuits]()

Flexible Printed Circuits