Glass Nano Imprint (NIP)

By molding hyperfine structures on glass substrate using an inorganic material (sol–gel glass), we can provide optical elements with high thermal resistance, low thermal expansion, and high chemical resistance.

Product summary

By combining the unique sol–gel glass and nanoimprint technology NGS developed, it became possible to provide optical elements with hyperfine structures made of glass material. We are capable of molding diverse nanostructures such as V‐groove, blazed, rectangle, or moth-eye. By using the nanoimprint technology, we are capable of manufacturing optical elements with lower cost than conventional technologies. The processed glass material possesses high thermal resistance, low thermal expansion, and high chemical resistance, enabling the optical elements to provide superior performance.

Optical design: We are also capable of simulation, providing customized design, prototype production and manufacturing service that match the demands of our customers.

Features of glass nanoimprinting

① As it is made of sol–gel glass, the formation of optical elements with high thermal resistance, low thermal expansion, and high chemical resistance is possible.

② As imprinting from hyperfine molds are used, we can provide elements with good morphological stability.

③ As we are capable of molding structures close to the wavelength of light, it is possible to mold elements that can freely control light, such as diffractive optical element.

④ With formation using sol–gel glass, we are capable of producing structures higher than a few µm.

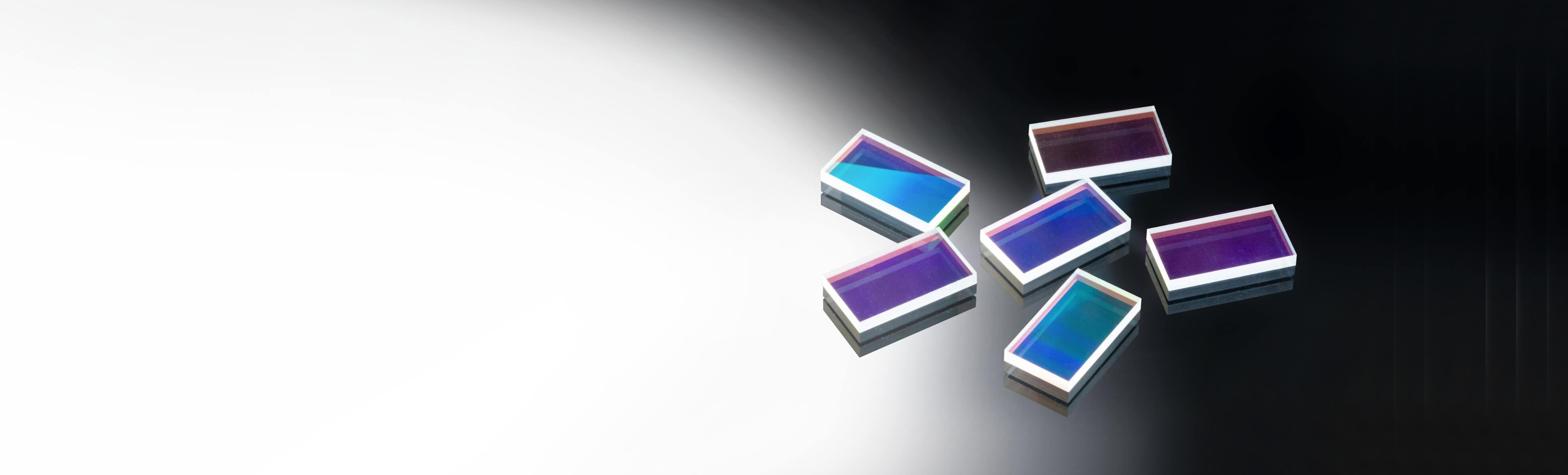

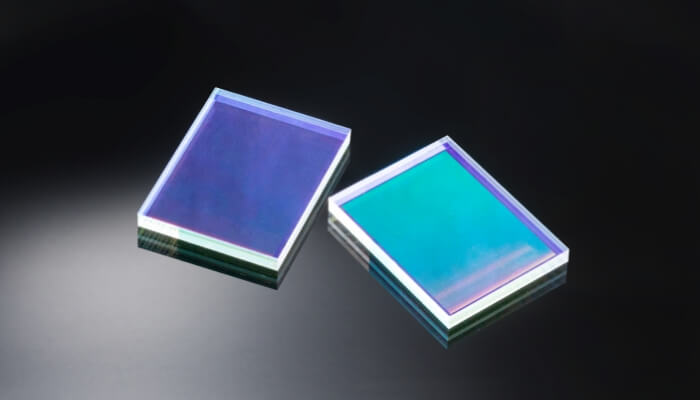

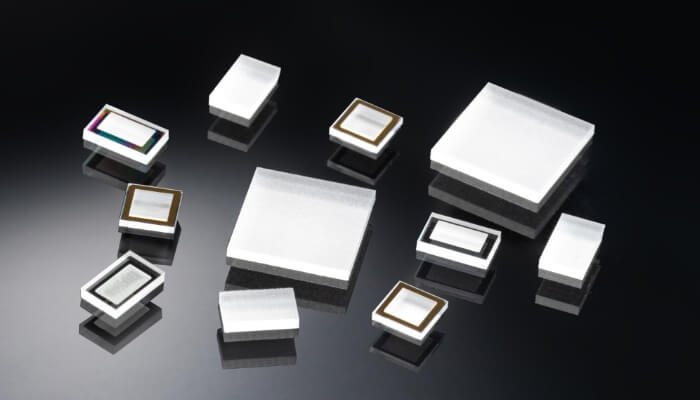

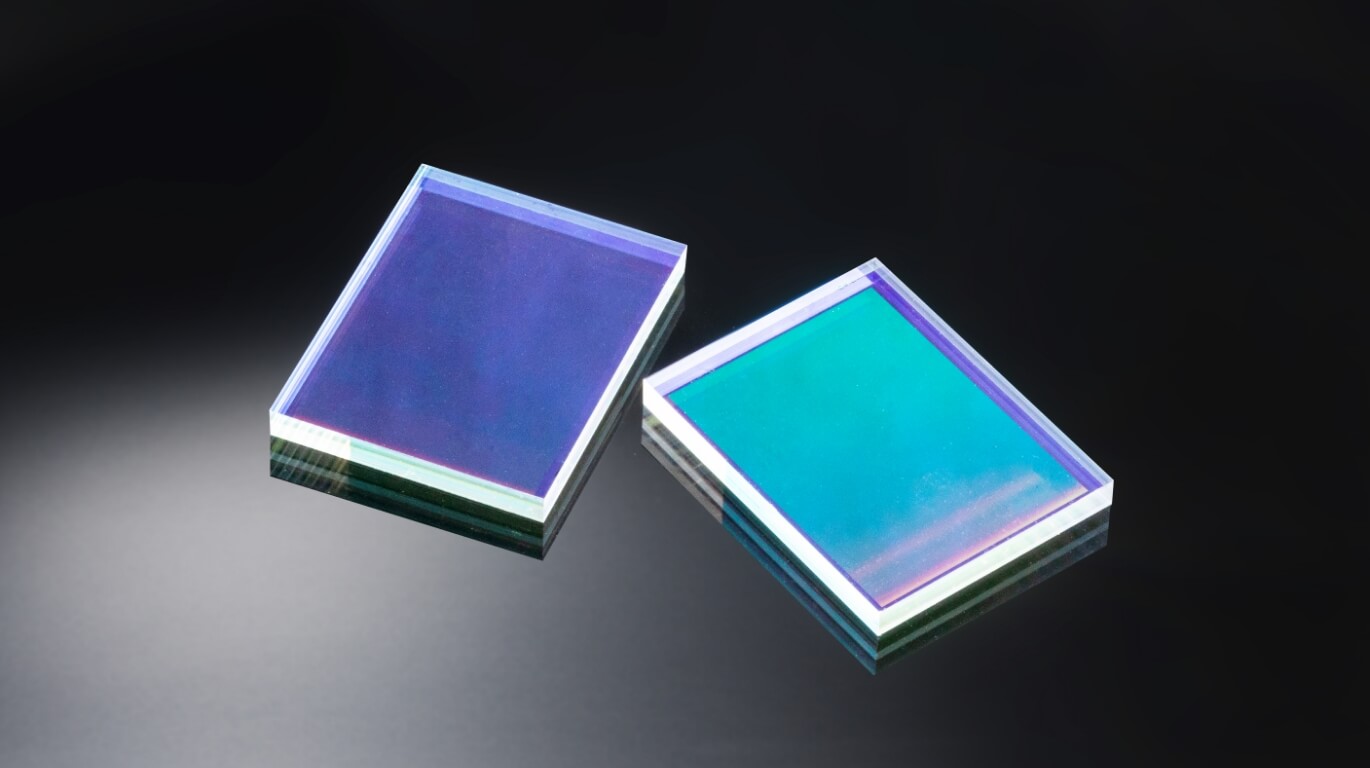

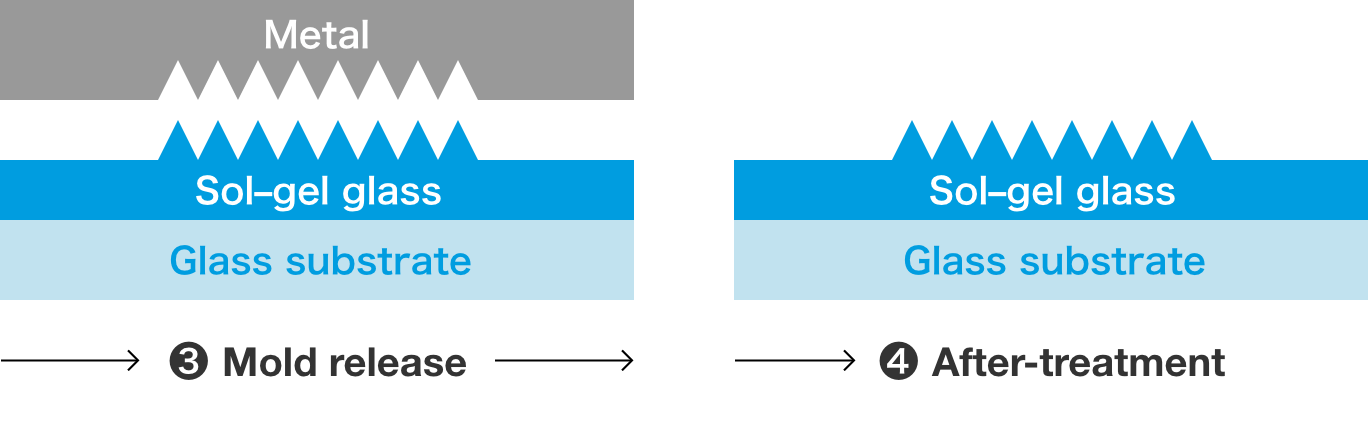

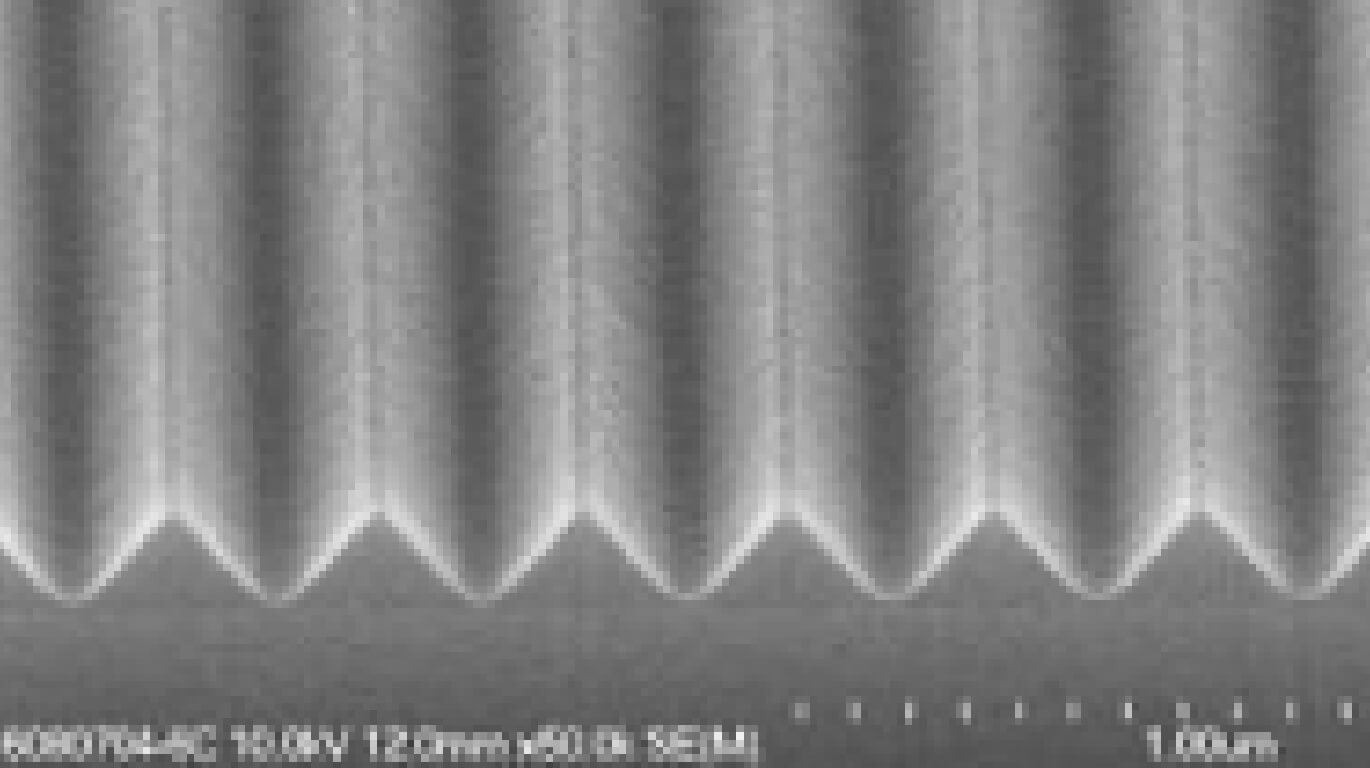

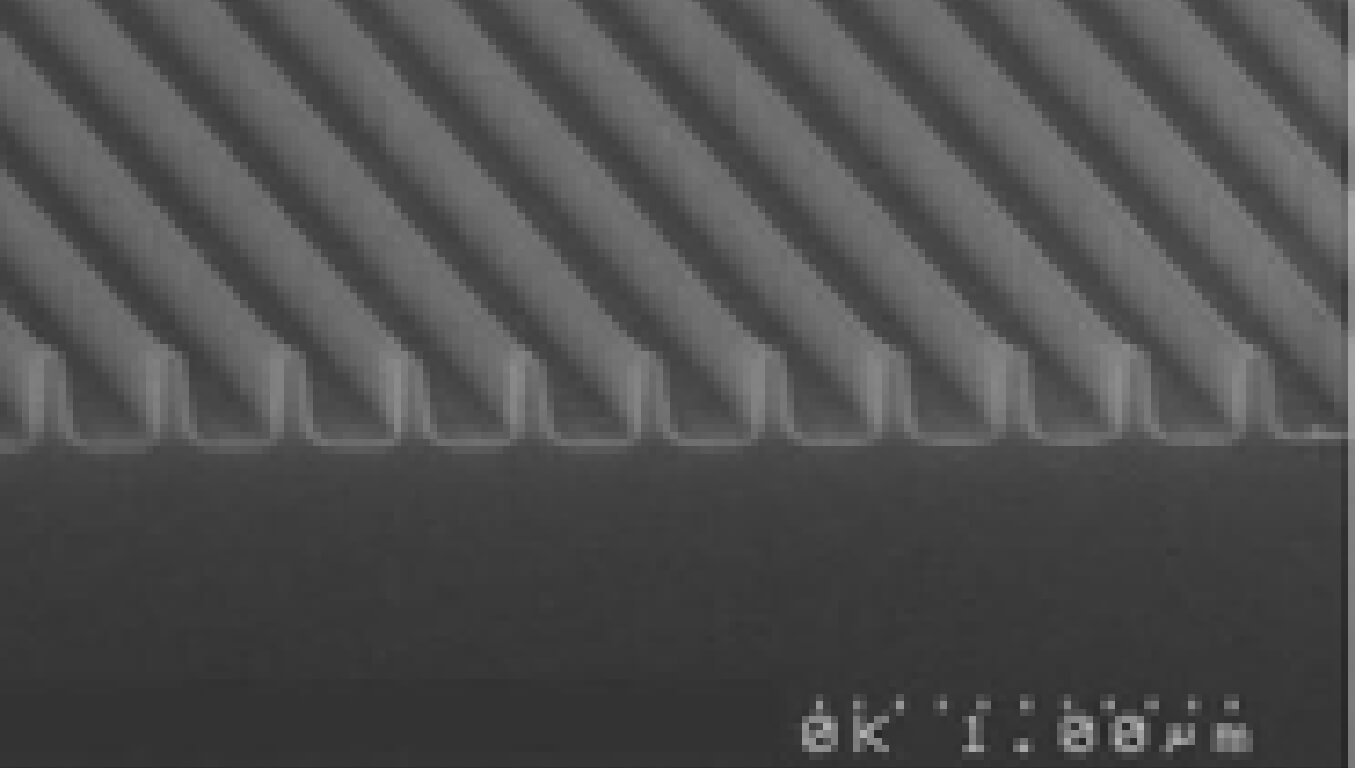

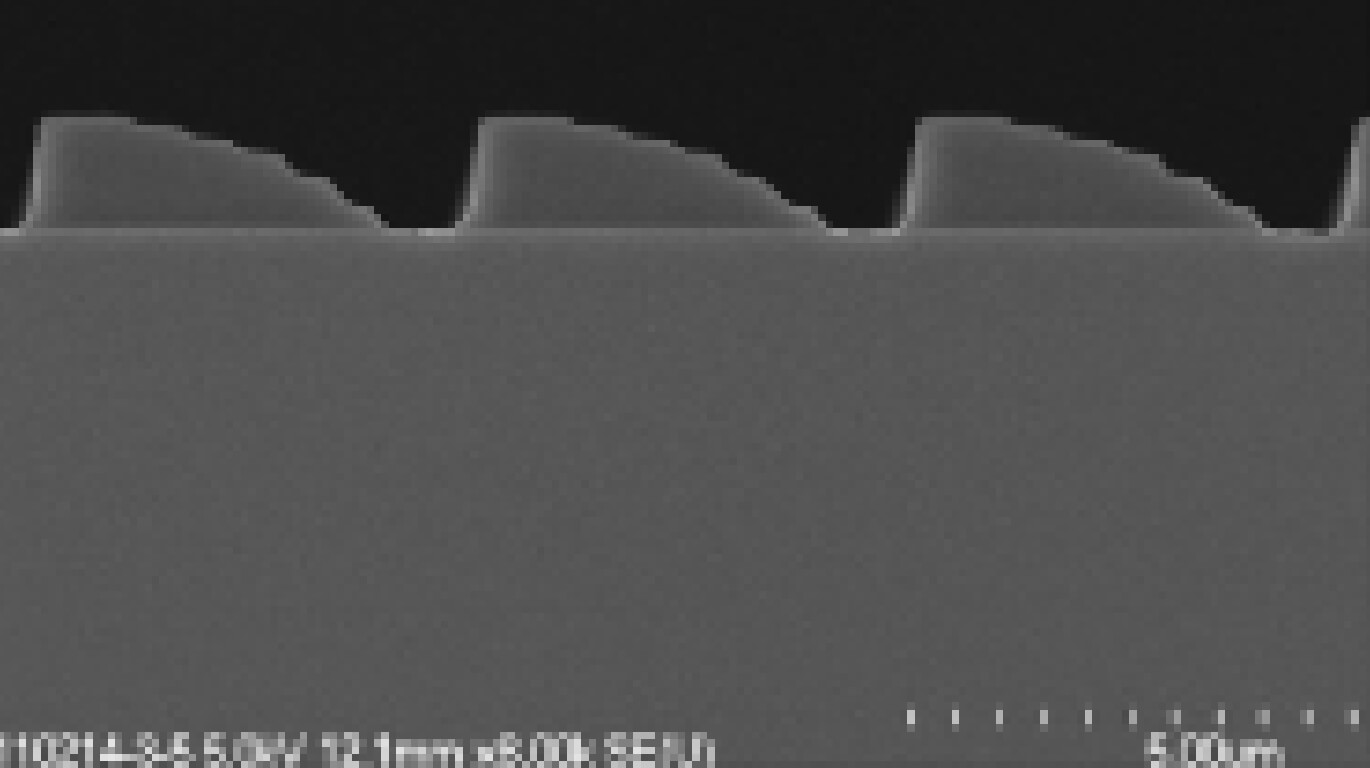

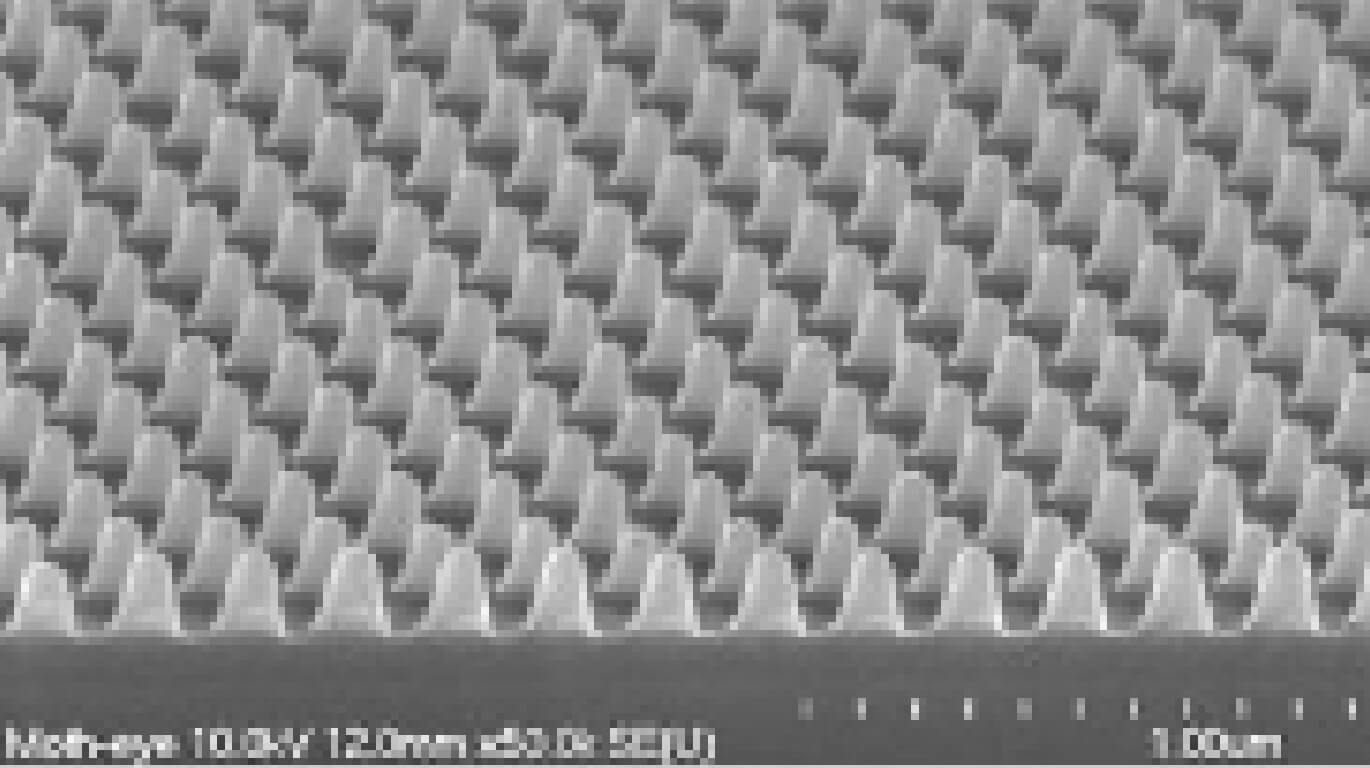

Appearance of diffraction grating molded through glass nanoimprinting

Optical elements made of sol–gel glass with high thermal resistance, good light resistance, low thermal expansion, and high chemical resistance.

As we use the unique sol–gel glass NSG developed, we are capable of providing optical elements with high thermal resistance, low thermal expansion, and high chemical resistance. Moreover, by performing high temperature sintering during the after-treatment, we can turn them into a fused silica structure.

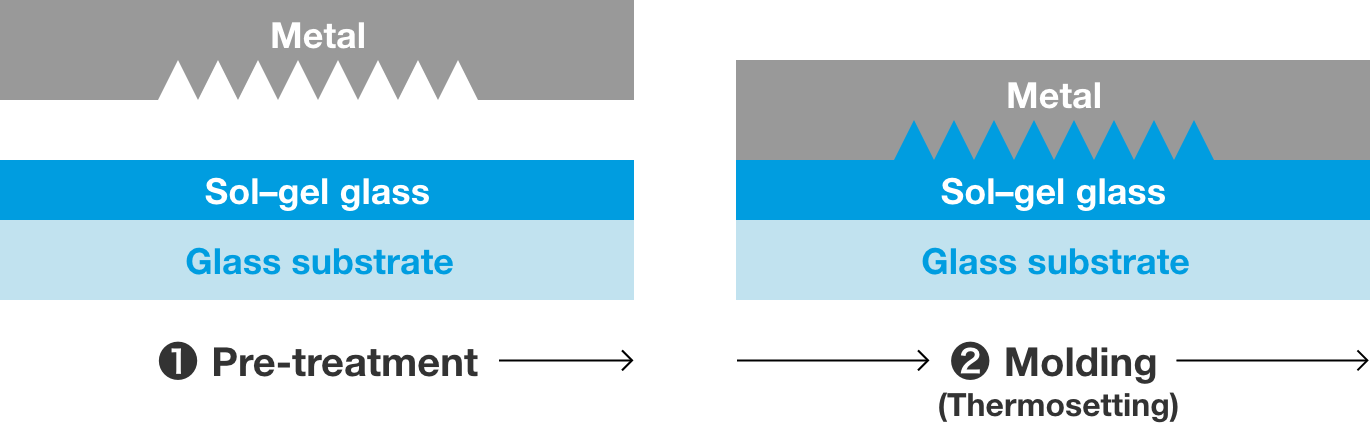

Process of glass nanoimprinting

Glass nanoimprinting uses the unique sol–gel glass NSG developed as the molding material. As the molds are produced through methods such as EB or laser drawings, extremely fine structure can be created, and as it transfers on glass surface through is an imprinting technology, this glass processing method has good form reproducibility.

The molding method involves the coating of a glass substrate with the sol–gel glass, pressing the mold on it and thermosetting, resulting in a relief structure on the surface. Moreover, it is possible to perform vacuum deposition, such as AR coating, during the after-treatment.

Various shapes

We are capable of producing hyperfine structures in various nano-orders.

Examples: ① V‐groove

Examples: ② Rectangle

Examples: ③ Rectangle

Examples: ④ Blazed

Examples: ⑤ Moth-eye

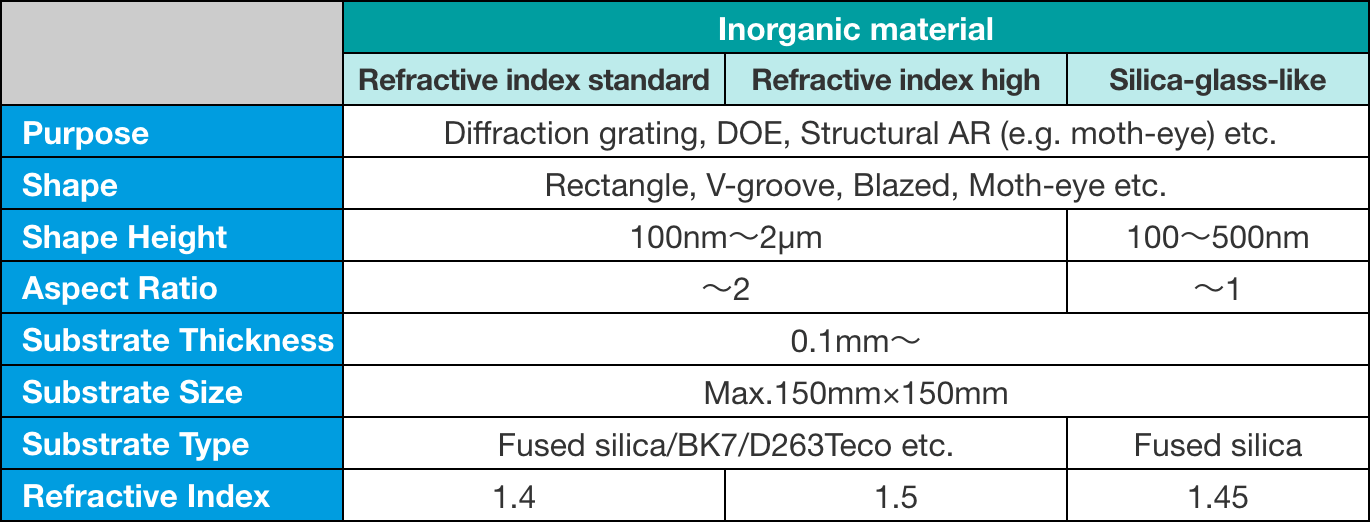

Reference specification

The reference specifications table lists the structures we can produce as prototypes. There are cases where structures that are not listed in the table can be produced. Please make an inquiry for details.

Reference specification

Glossary

Sol–gel glass

Glass produced through the sol–gel method.

Sol–gel method is a glass molding method whose starting material is a solution where glass can be formed with a relatively low temperature.

Nanoimprinting, Imprinting

The method to reproduce nano-order structures through transfer technology.

Diffractive optical element

Diffractive optical element (DOE) is a type of optical element that controls the interference from light through hyperfine relief. By controlling the interference from light, it can control divergence, spectral diffraction and deflection of light. As it allows effective irradiation onto specified areas, it is expected to be used as lighting elements or optical sensors.

Diffractive grating

A diffraction grating is an optical component with a periodic structure that diffracts light into several beams travelling in different directions. The directions or diffraction angles of these beams depend on the wave (light) incident angle to the diffraction grating, the spacing or distance between adjacent grooves on the grating, and the wavelength of the incident light.

Moth-eye

The moth-eye pattern is a pattern of subwavelength “bumps”; reduces reflection by creating an effective refractive index gradient between the air and the medium.

V-groove

Triangular cross section structure.

Blazed

sawtooth wave-like cross section structure

EB drawing

Electron beam drawing. A drawing method using electron beam. It is capable of forming extremely fine patterns in a few nm to a few dozen nm resolution. However, its throughput is low as it uses extremely small spots for the drawing.

Laser drawing

A drawing method using laser beam. While its resolution is not as good as that of EB drawing, it is capable of forming fine patterns with sub-μm resolution. Compared to EB drawing, it has better throughput and at working on large area.

AR coating

Coating of antireflection film. It coats a film that reduces the reflection from the substrate by using interference from light.

Fused silica

Fused silica. Glass made of silica (SiO2) with high SiO2 purity.

BK7

A product of Schott. Borosilicate glass crown glass. It is well-known for its versatility as a optical glass, and it is used as a material for lenses and prisms.

D263

A product of Schott. Borosilicate glass. It is a product with high chemical resistance.

FAQ

Do you have glass nanoimprinting samples?

It is currently under consideration.

Can you produce prototype if a metal mold is provided?

Yes, however, depending on the type of the mold, it may not be possible. We will discuss it prior to the production.

Contact usAre there shapes you cannot mold?

We have experience in producing structures up to aspect ratio 2. Please make an inquiry for the structures beyond this.

Contact usCan you mold curved surfaces such as lens?

Generally, it is difficult. If the curvature is low, it may be possible. Please make an inquiry.

Contact usCan you design optical elements such as diffraction grating?

Yes, we can.

How long does it take to complete a prototype?

It depends on the type of element you request. We will discuss it case by case.

・If you are supplying the metal molds: Two to three weeks.

・If it involves designing of optical elements and metal mold production through EB drawing: Three to five months.

Can you produce prototype if substrates are provided?

It is possible. We will discuss it prior to the production.

Contact usDo you have a list of the physical properties of the sol–gel glass?

It is being prepared.