Glass Cord/RICS - Rubber/Resin Reinforcement

Long fiber products made of a glass, carbon, and aramid for rubber and resin reinforcement are created using NSG's unique technology.

Product summary

MICROGLAS® Glass Cord and RICS are long fiber products made of glass, carbon, and aramid fibers treated with a special adhesive to enhance its adhesion to rubber and resin.

They have high strength, durability, and heat resistance, which makes them suitable for reinforcing rubber and resin products.

MICROGLAS® Glass Cord is a continuous fiber in the form of yarn or cord. MICROGLAS® RICS is a fiber product in a chopped strand form where the fiber is cut to a specific length.

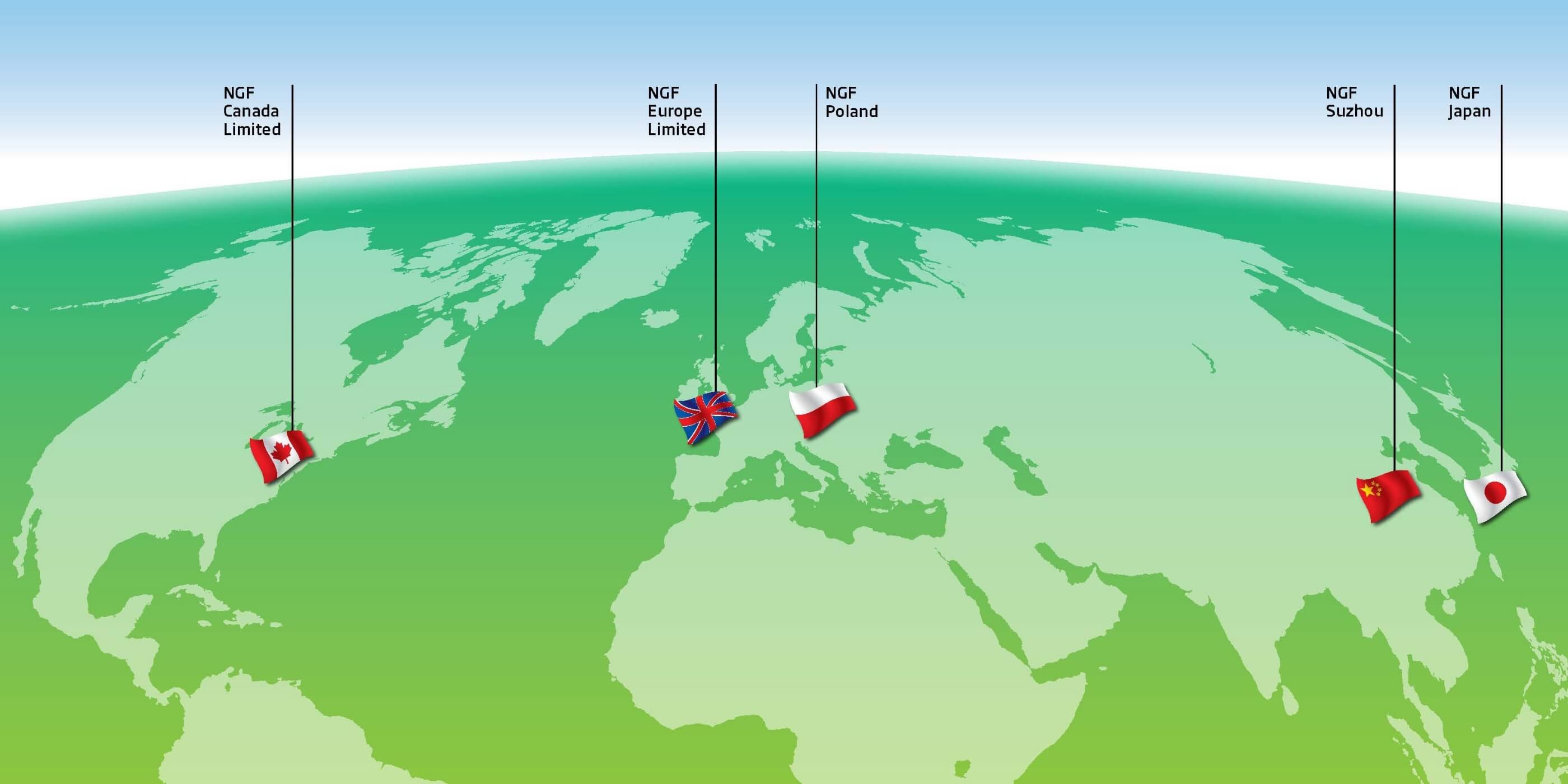

NGF is a global company with manufacturing locations in Europe, North America and Asia,and is part of the NSG group of companies.

About NGF

NGF is a global business with manufacturing units in Japan, China, UK, Poland and Canada and is a member of the NSG Group of companies.

The group is a world-leader in the manufacture of glass products for building, automotive and information electronics applications.

NGF is the only glass cord manufacturer that can produce high tensile strength glass cord from fibre forming to finished product.

This can be done in both the Japanese and UK facilities.

Product features and strengths

Strength and Durability:

The superior strength and durability of glass, carbon, and aramid fibers enable the reinforcement of the rubber and resin products. Furthermore, they have the capability to improve abrasion and tensile resistance.

Heat resistance:

Glass and carbon fibers have high heat resistance and can be used in high temperature environments. Composites with these rubber and resin products improve heat resistance and ensure stability under high temperature.

Lightweight:

Glass, carbon, and aramid fibers are lightweight yet strong, thereby contributing to weight reduction and performance improvement of rubber and resin products."

Extrusion profiles

The Glass Cord is used as a reinforcing material for extruded rubber molded products such as automotive sealing materials and weather strips.

The low elongation and high tensile strength of the Glass Cord improves the strength and dimensional stability of the extruded rubber molded products, preventing viscous deformation and shrinkage even during long-term use.

Additionally, the high dimensional stability of the Glass Cord will improve production output leading to more accurate cut lengths during the assembly process of weather strips and other products.

Tires

Glass Cord and RICS are used as reinforcement materials in automotive and bicycle tires.

Reinforcing high-performance tires with Glass Cord extends tread life and ensures smooth running performance by improving heat dispersion and increasing tensile strength.

The RICS also reinforces rubber tires and prevents cracking and chipping of the tread surface when driving on uneven surfaces.

RICS is a glass or carbon fiber product with the fiber lengths of 1, 3, or 6 mm that has been treated with an adhesive for rubber products (RFL treatment).

Woven cloth/mat shape

Woven fabrics using Glass Cord improves the molding stability of the rubber molded products with complex structures, such as escalator handrails.

The excellent adhesion of glass cloth treated with adhesives and woven with glass cord improves strength, reduces delamination and damage in the laminated areas of rubber molded products during use. Similar fabrics are used for dryer felts and conveyor belts

Rubber hose

The dimensional stability, low elongation, high elastic modulus, high flexibility, and excellent weather resistance of Glass Cord contribute to the improved performance of rubber hoses.

The excellent adhesion to rubber is due to the adhesive treatment improving the strength and reducing the delamination of laminated parts in rubber hoses as well as its wear and tear during use.

Other applications

MICROGLAS® Glass Cord and RICS contribute to increasing functionality and adding values in various materials used in industrial fields, including reinforcing materials for sports equipment such as gloves, shoes, and fins; cushioning materials for vibration control and soundproofing; filament materials for 3D printers; rubber products for outdoor use (rubber mats, rubber tiles, rubber boots, etc.); rubber rollers; rubber crawlers; rubber pipes and piping; rubber packing; rubber sealing; and nichrome wire.

Glass Cord

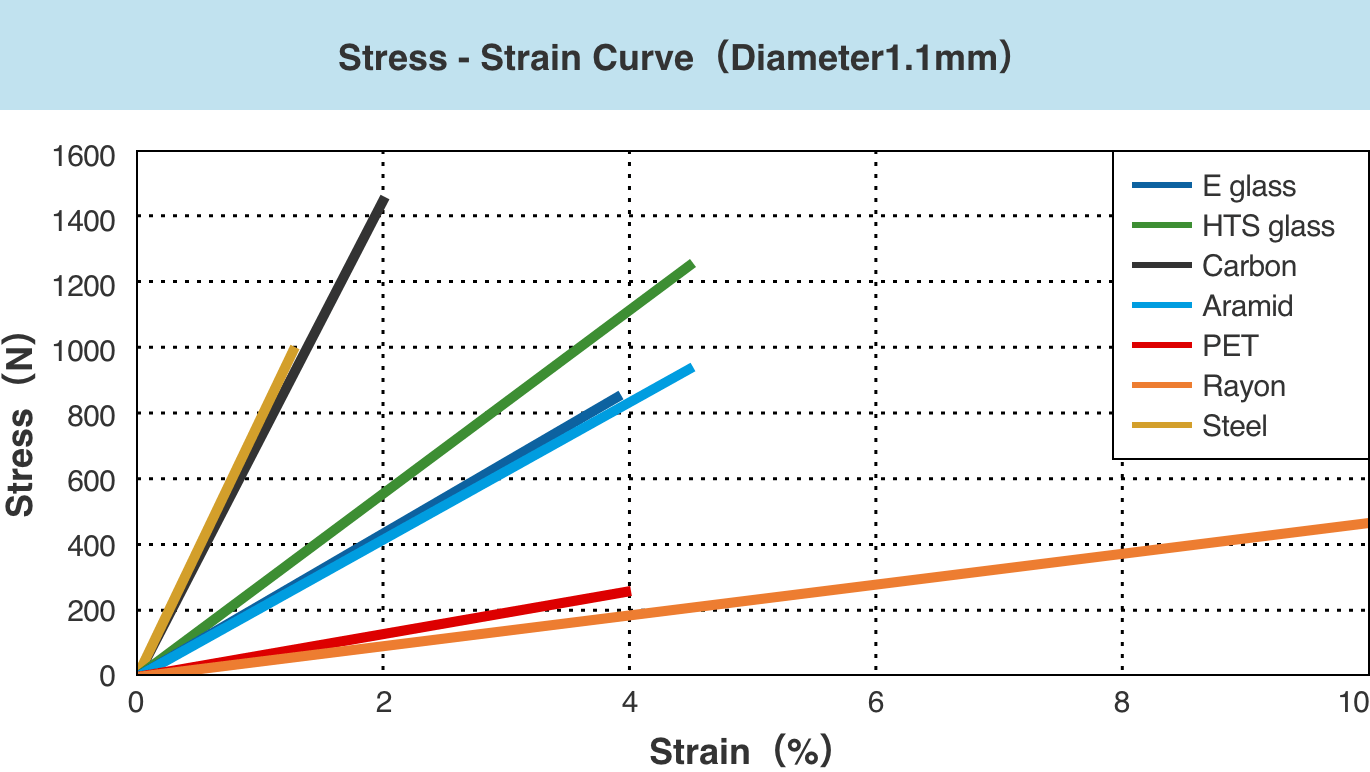

Glass Cord is a long fiber product made of glass fiber (E-glass, high-strength glass) and other high-performance fibers (carbon and aramid) treated with a special adhesive to enhance adhesion to rubber and resin.

Glass has a modulus of elasticity equivalent to that of aramid, and has excellent dimensional stability and flexural fatigue resistance.

Carbon fiber has a modulus of elasticity similar to that of steel fiber and offers the advantages of dimensional stability, excellent flexural fatigue resistance, and light weight.

By changing the fiber thickness, twist direction, and number of twists, it can be used in various applications.

RICS

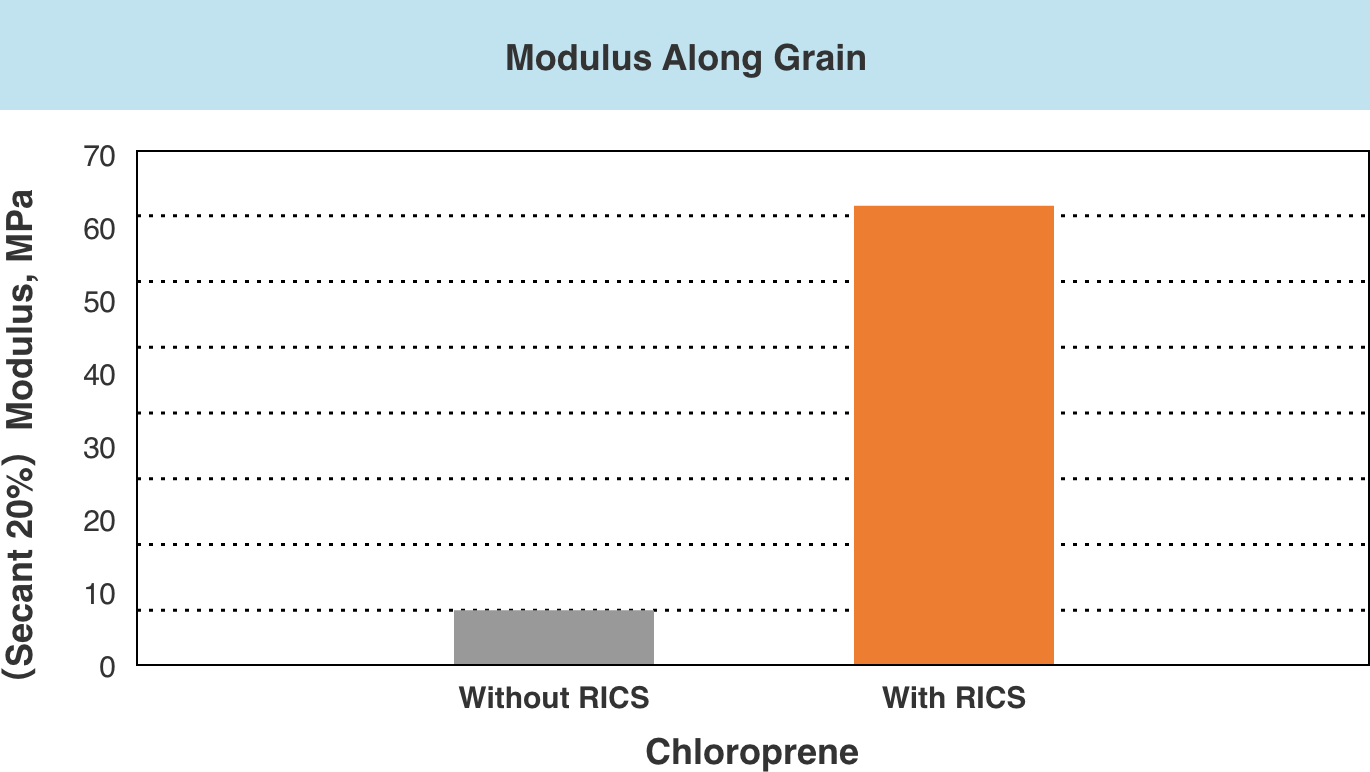

RICS stands for Rubber Impregnated Chopped Strands and is a fiber product in the form of chopped strands with adhesive impregnated into the fibers. It can strengthen composite materials such as rubber and resin.

Fibers can be selected from glass fiber, carbon fiber, and aramid fiber.

Like Glass Cord, it is treated with a special adhesive, making it easier to handle than untreated chopped strands and providing superior adhesion to rubber and resin.

Glossary

Glass Cord

Long fiber products made of glass, carbon, and aramid fibers as well as other high-performance fibers are treated with a special adhesive to enhance adhesion to rubber and resin.

RICS

Rubber Impregnated Chopped Strands. Products in the form of chopped strands that can strengthen rubber and plastic composite materials.

Chopped Strand

Chopped strands are made by cutting fibers to a specific length.

High Strength Glass

This glass is made by improving the composition of the glass normally used (E-glass), thereby increasing its strength. K-glass, U-glass, and other types of glass are available.

FAQ

How thick is the cord?

It varies from product to product, but its diameter is approximately 0.2–5.0 mm.

Can we discuss the possibility of using the product for the application we are considering?

We can accommodate your needs regarding the cord diameter, type of rubber to be reinforced, desired strength, etc. Please make an inquiry to discuss your needs.

Contact usCan you provide samples?

Yes, we can provide you some samples. However, you need to sign a non-disclosure agreement (NDA) before receiving the samples. Please contact us for details.

Contact usWhat is the price and delivery time?

Please contact us for details.

Contact usCan you offer products other than cord or chopped strand shapes?

Please inquire separately for other shapes.

Contact usCompany Profile

NGF is a global business with manufacturing units in Japan, China, UK, Poland and Canada and is a member of the NSG Group of companies. The group is a world-leader in the manufacture of glass products for building, automotive and information electronics applications.

NGF is at the forefront of the design, manufacture and marketing of specialised glass cord products used in synchronous drive applications. Carbon Fibre, Aramid and Hybrid cords are also part of the company’s portfolio.

Primarily used in the automotive industry, NGF cord is also used in belts for domestic appliances as well as industrial machinery, office equipment and power tools.

By far the best example of a synchronous drive belt is the automotive timing belt. Recent developments in high tensile strength glass cord technology from NGF have revolutionised the way today’s automotive engineers design vehicles.

NGF is the only glass cord manufacturer that can produce high tensile strength glass cord from fibre forming to finished product. This can be done in both the Japanese and UK facilities.

The new generation of small filament diameter glass cords are uniquely oil-resistant and so capable of reinforcing timing belts which run in oil, leading to greener, quieter more fuel-efficient vehicles.

NGF Europe, based in the United Kingdom, received the Queen's Award for Enterprise: Innovation during 2014 in recognition of its patented technology.

The company also holds the Queen's Award for Enterprise: International Trade which it gained in 2001.

Thanks to its unparalleled global reach, NGF is able to supply products to markets in all the major car-manufacturing countries world-wide.

Global Reach

NGF is a member of the Functional Products Division of the Technical Glass Strategic Business Unit within the NSG Group.

This global organisation is strategically well placed to service all the major regions of the World.

Document download