FLEKA®

FLEKA® is granularated glass flake material with surface treatment, contributing to prevent warping and to realize dimensional stability of engineering plastic products.

Product summary

FLEKA® is a granulated glass flake which, using proprietary development and manufacturing, has a mean thickness of 5µm, a high aspect ratio of 10-4000µm (thickness/particle size ratio), which has been surface-treated to improve compatibility with resins.

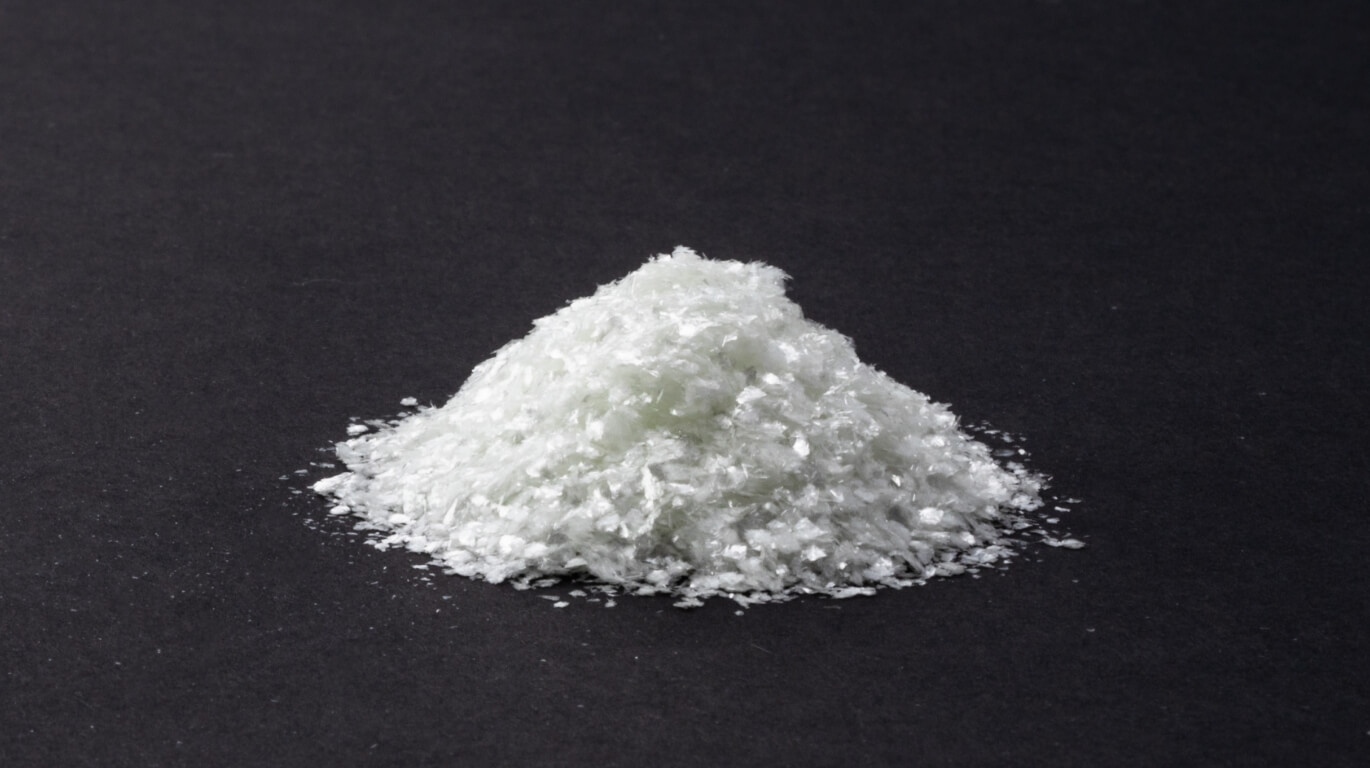

The flakes are prevented from scattering and the handling is improved using a unique surface treatment technology, and adhesion to various resins is improved. It also exhibits excellent solubility within the resin so the glass flakes are oriented in a uniform manner. FLEKA® allows improvement of engineering plastic dimensional accuracy across three dimensions.

Development of 3-D dimensional stability

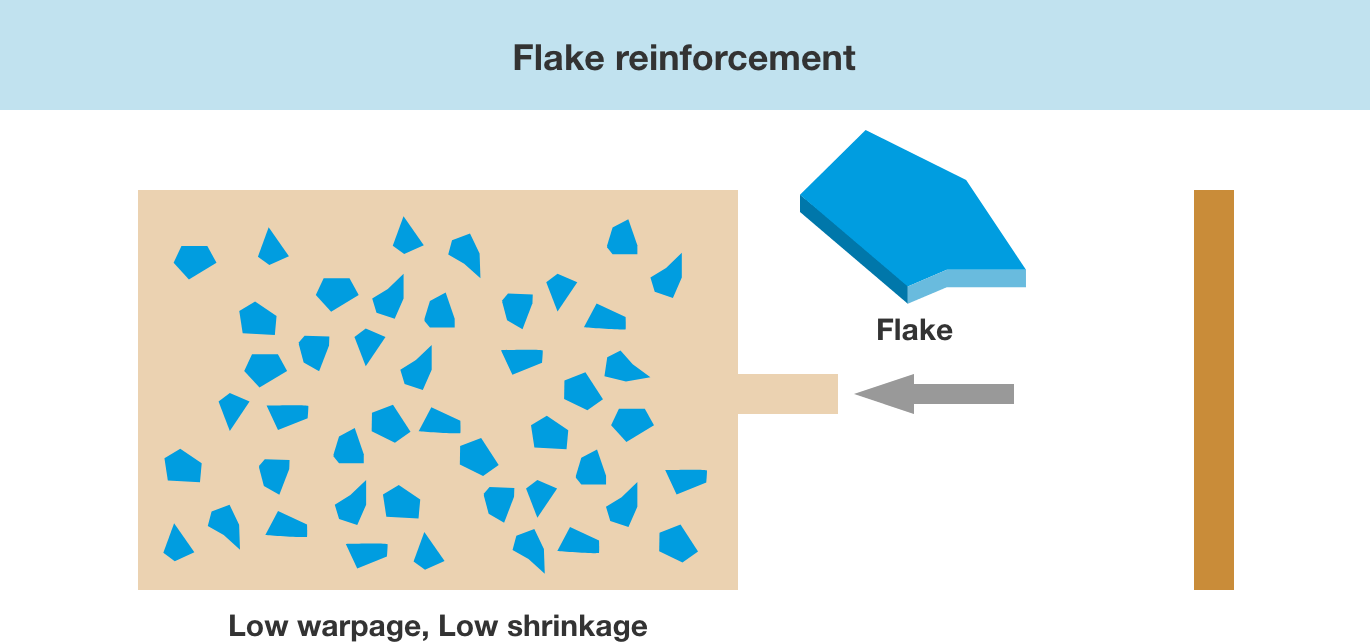

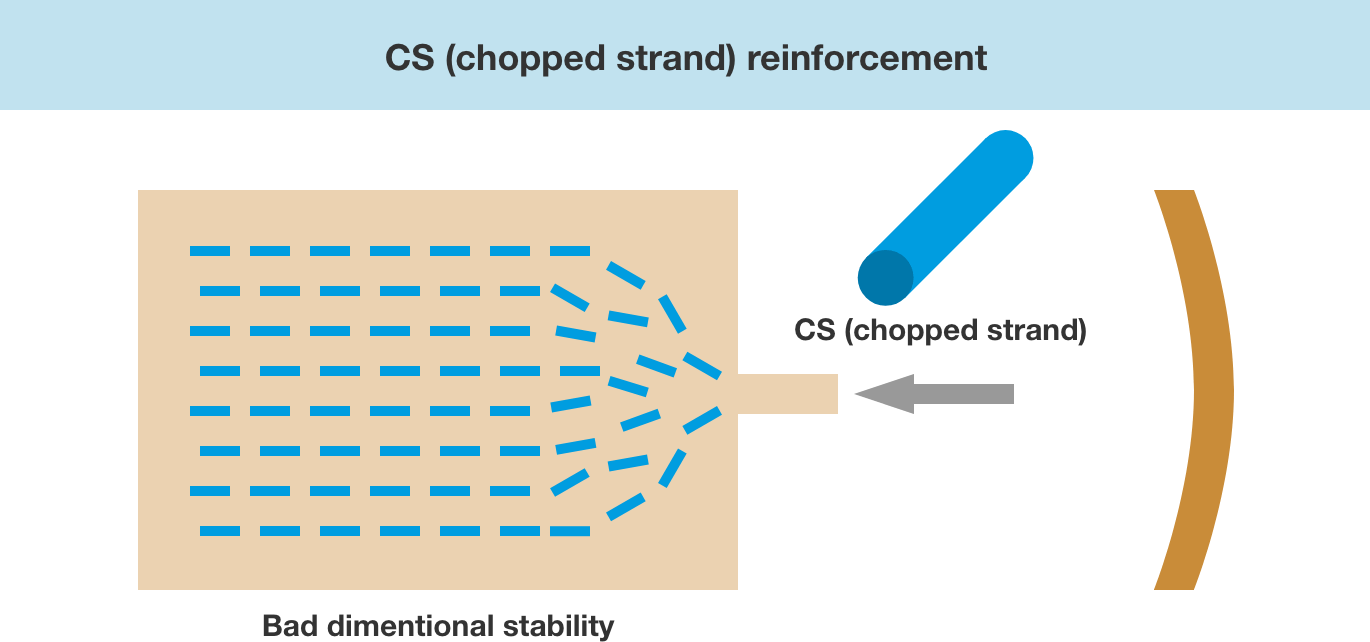

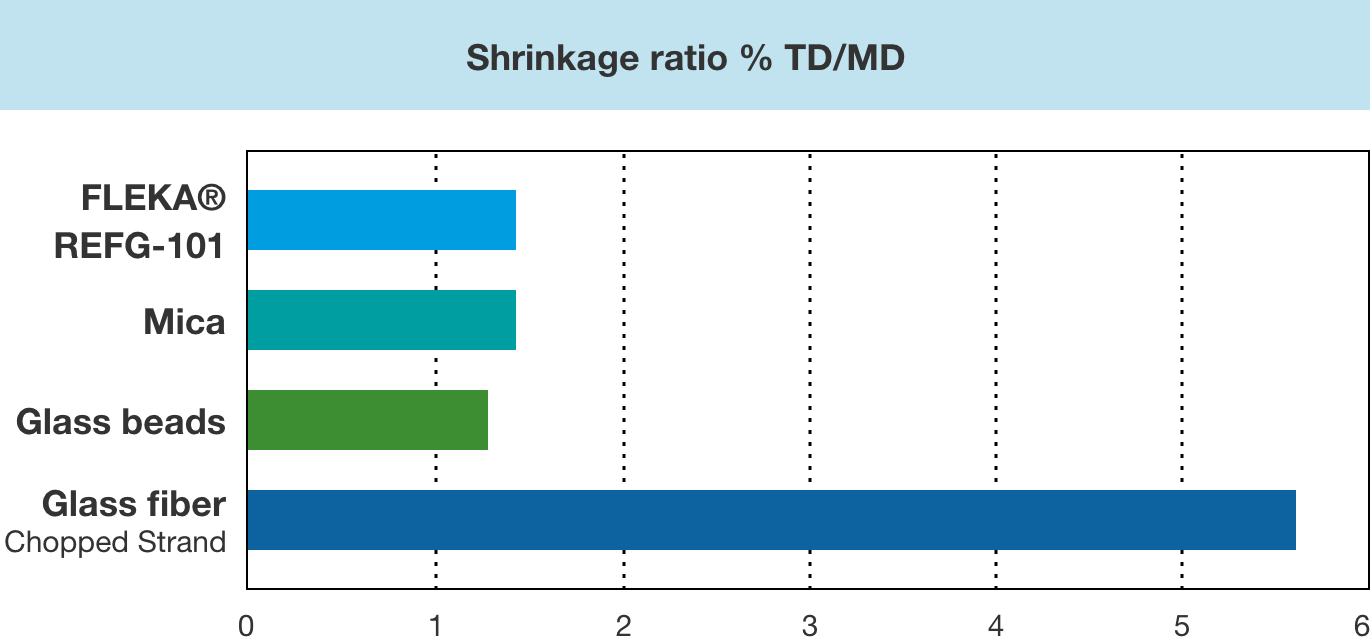

Flake shape glass particles that have a high aspect ratio (thickness/particle size ratio) are oriented parallel to the resin surface. This is effective to control dimensional changes not only in resin flow direction (MD direction) but also in vertical direction (TD direction) (MD/TD gets close to 1). This enables molded product to reduce warpage significantly.

Resinforcing resin with flake shape glass filler (glass flakes: platelet shape)

Reinforcing resin with chopped strand (glass fiber: fibrous)

Effect by surface treatment and granulation technology

(1) Adhesion improvements to various thermoplastic resins (PC, PBT, PA, PP, PPS, LCP, etc.)

(2)Using granulation to improve handling workability (improvement of product flowability = hopper bridge reduction , scattering prevention)

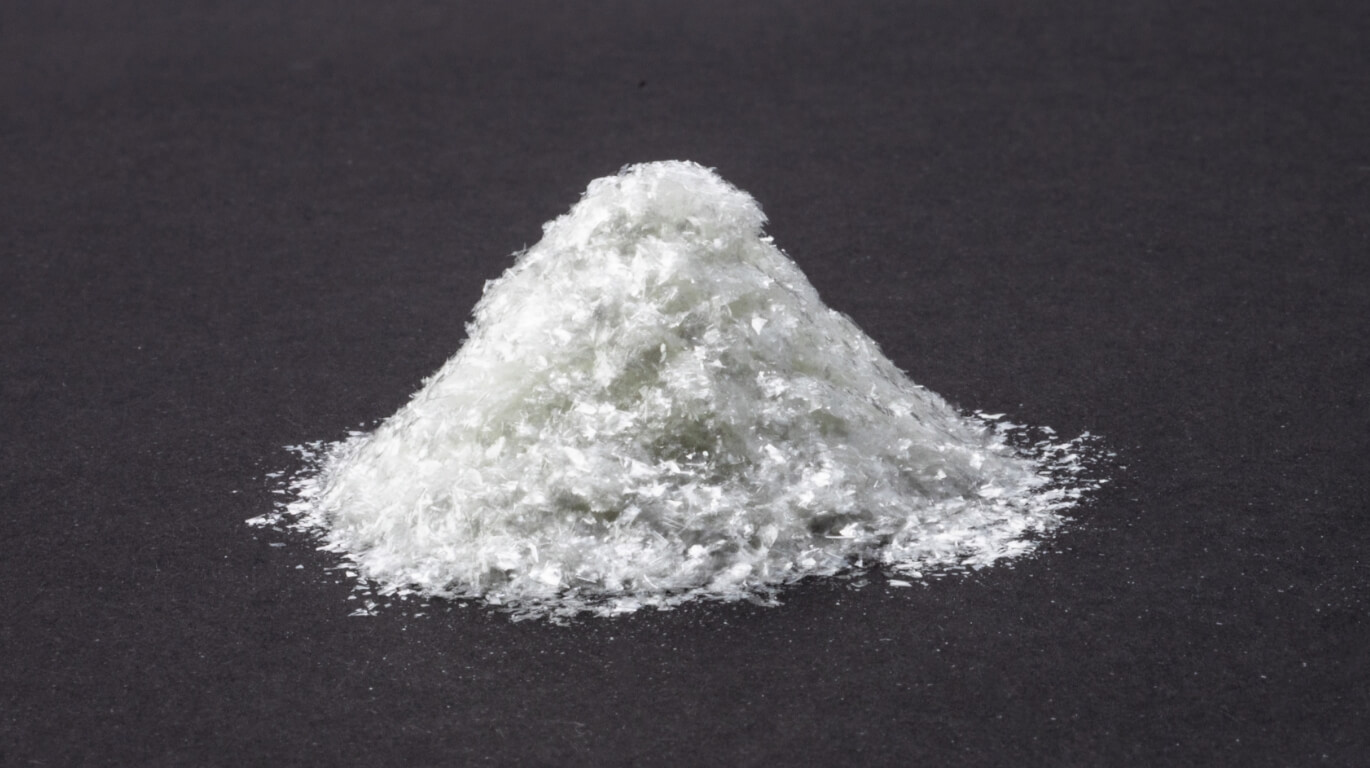

REF-600 (nontreated, nongranulated)

REFG-101 (with surface treatment, REF-600 granulated version)

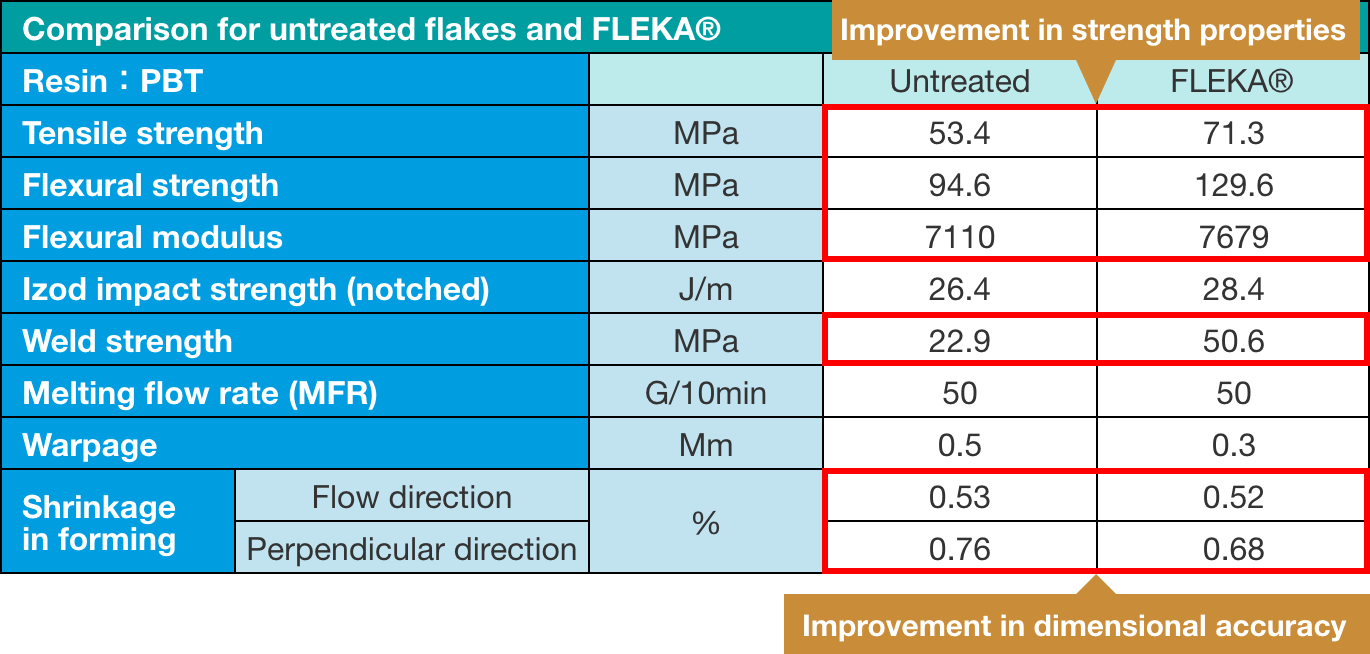

Improvements in dimensional stability during injection molding

High dimensional stability during injection molding (warpage and molding shrinkage reduction)

Comparison of dimensional stability in PBT resin (FLEKA®, mica, glass beads, glass fiber)

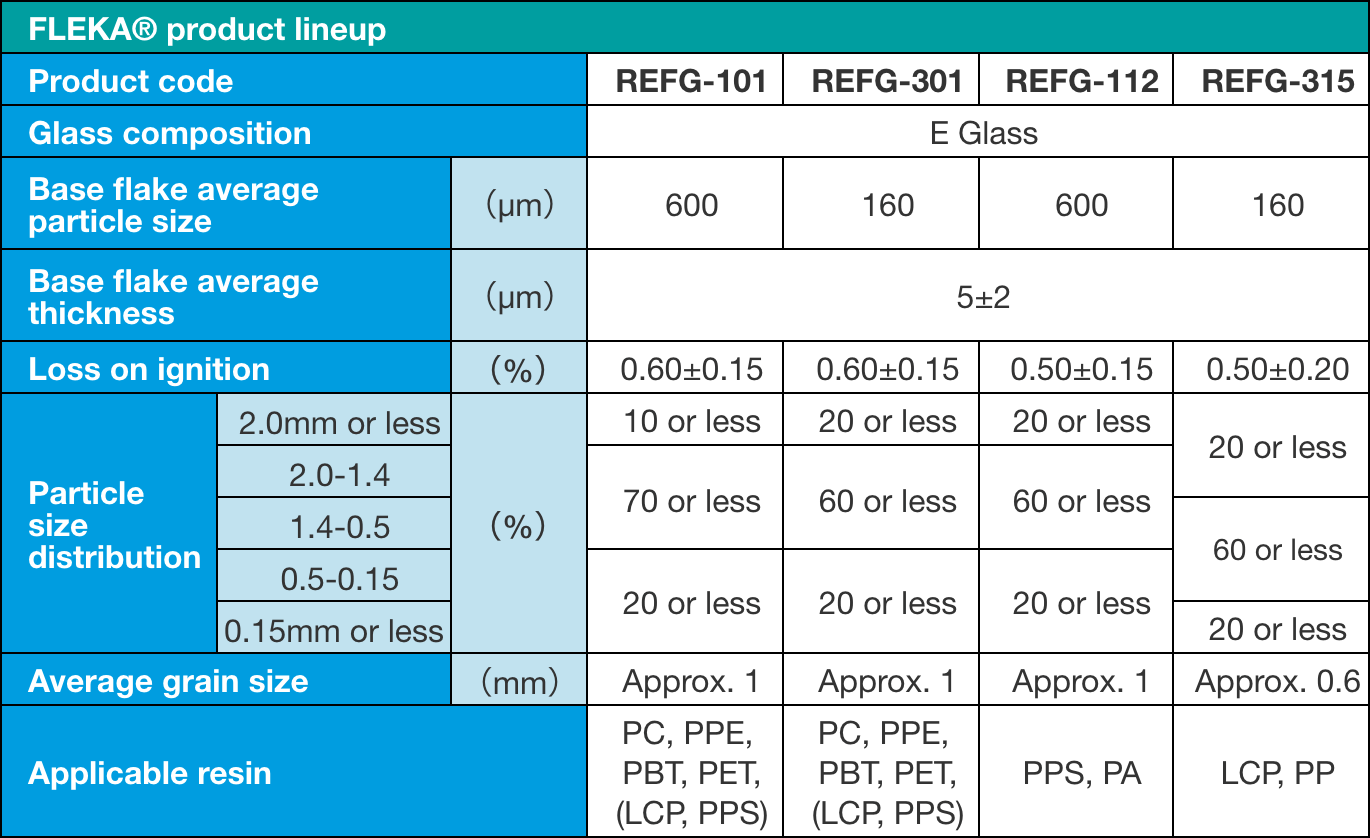

FLEKA® product lineup and the effect of surface treatment

Raw glass flakes have average thickness of 5µm, two types with two mean particle size of 160µm and 600µm are available. Both glass flakes are granulated with a surface treatment customized to the resin.

Surface treatment is expected to improve adhesion to resin and physical properties of the molded products such as tensile strength and bending strength. Granulation provides good handling (workability) for glass flake.

FLEKA® product lineup

Change in physical properties with and without surface treatment

Glossary

Bulk density

This is a value obtained from the weight of a fixed volume and is expressed in units such as g/cm3. A value of 1 is the same as water, and the smaller the value, the greater the bulk.

Granule

This refers to the state of granulation after applying a surface treatment agent to glass flakes.

Adhesion

This shows the level of sticking status between glass flakes and resin or paint to be filled by the flake.

FAQ

How much is the bulk?

This depends on the product, but is approximately 0.2-0.5g/cm3.

How is it packaged?

Basically, 20kg of flake is packed by paper bag.

Depending on the quantity, NSG can also prepare a flexible container, so please feel free to inquire.

Could you send us a sample?

Yes, we can. Please use the inquiry form on our website or request it by phone.

Contact usFlake shape glass filler products list

NSG offers a variety of flake shape (scale-shaped) glass fillers to suit different granular sizes and applications.

For details on each product, please see the links in the table below.

| Products | Mean particle thickness [um] | Mean particle size [um] | Product use |

| GLASFLAKE® | 2~5 | 15~600 | Anticorrosion / corrosion resistant paint |

| FLEKA® | 5 | 160~600 | High-performance resins |

| FINEFLAKE™ | 0.7 | 160 | High-performance resins |

| DURAFLAKE® | 0.35 | 140 | High-performance resins |

| Low-dielectric glass flakes | 0.3~0.8 | 1~160 | Printed circuit boards / Interlayer insulation |