GLASFLAKE®

GLASFLAKE® creates a highly tortuous barrier function and is used as an additive in protective coatings application for offshore coastal facilities and bridges. It is also effective in preventing warping of precision plastic or composite parts and improving dimensional accuracy.

Product summary

GLASFLAKE® is a scale-like glass particle having average thicknesses of between 1 to 7µm. Average diameter ranges between 10 to 4,000µm. Because it mainly used in the industrial applications, GLASFLAKE® with C glass composition is used in the protective coating and lining areas as a highly-effective anticorrosion additive material. GLASFLAKE® with E glass composition is effective in preventing warpage and improving dimensional accuracy for precision engineered plastic parts.

C glass contains alkaline components, equipped to resist highly-acidic environments. E glass contains very little alkaline component, providing a stable additive having a high level of electrical insulation in the finished compound.

GLASFLAKE® additives

C GLASFLAKE® is used in the anticorrosion paint with taking advantage of excellent acid resistance. E GLASFLAKE® is used as reinforcing additive to resin due to little alkali content and electrical insulation.

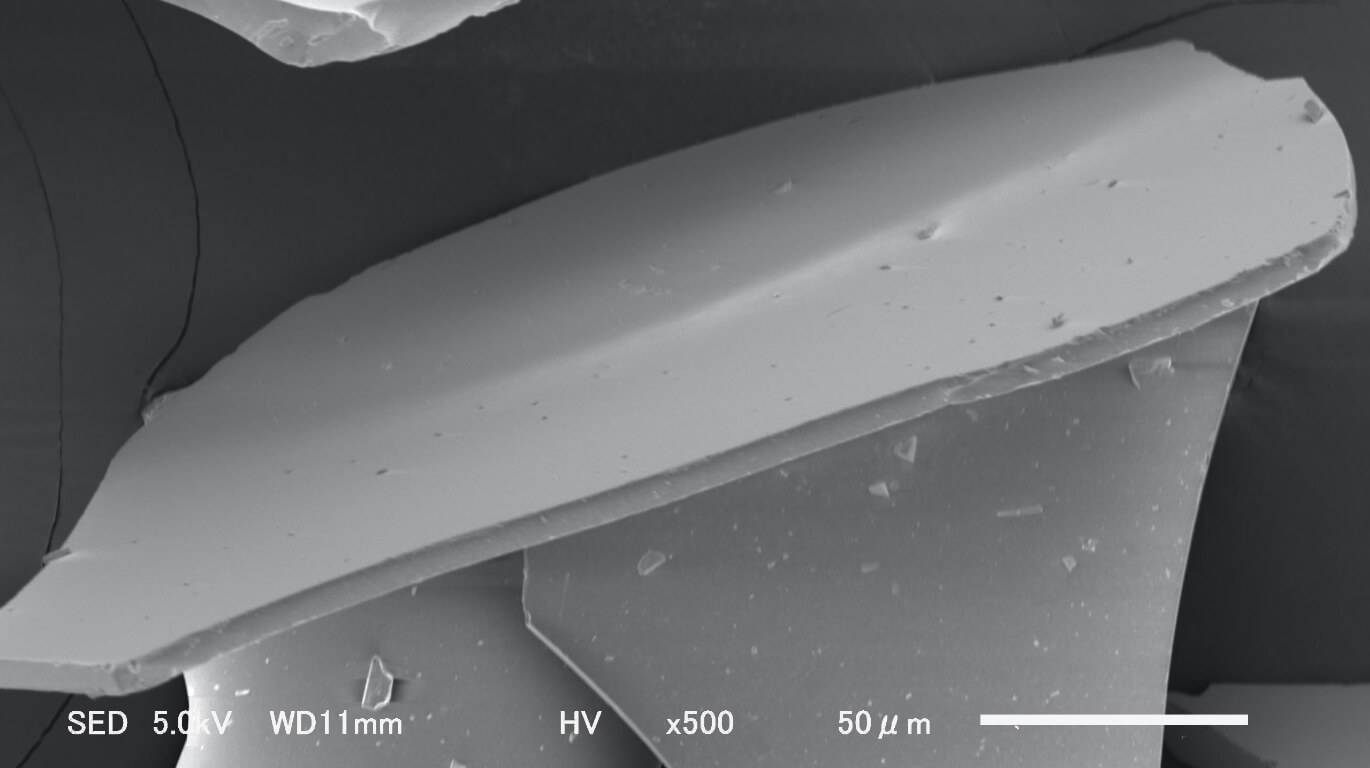

SEM images below represent REF-160 (ave thickness : approx 5µm, ave diameter approx 160µm)

* photo shows typical example, showing thickness and diameter have certain distribution.

SEM image of REF-160 (average thickness: ca. 5µm, average particle size: ca. 160µm).

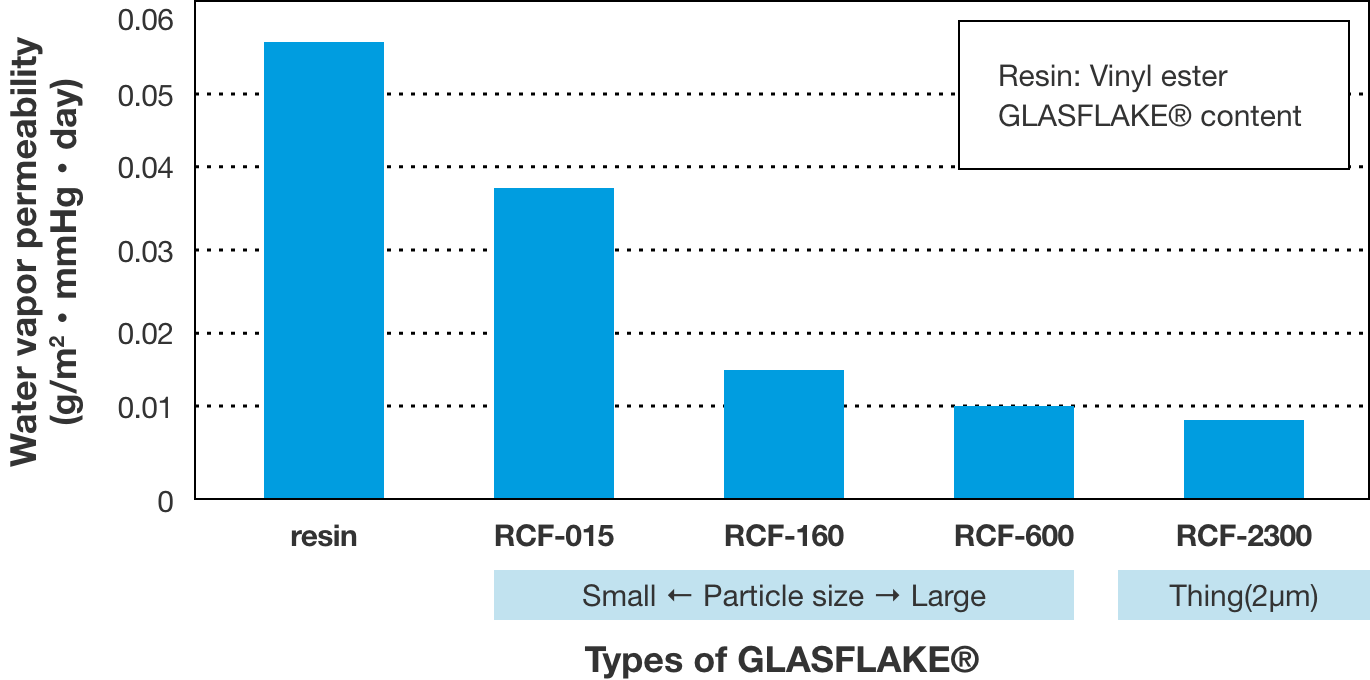

Effects of GLASFLAKE® (on water vapor permeability)

If water vapor permeability is measured when 30% GLASFLAKE® is added to vinyl ester resin, barrier effect is stronger with larger grain sizes (higher aspect ratio).

Products with the thickness of 2µm have a higher aspect ratio and a higher number of GLASFLAKE® sheets added; thus, its effect is stronger.

Influence from particle size of GLASFLAKE®

Longer service life of lining coating

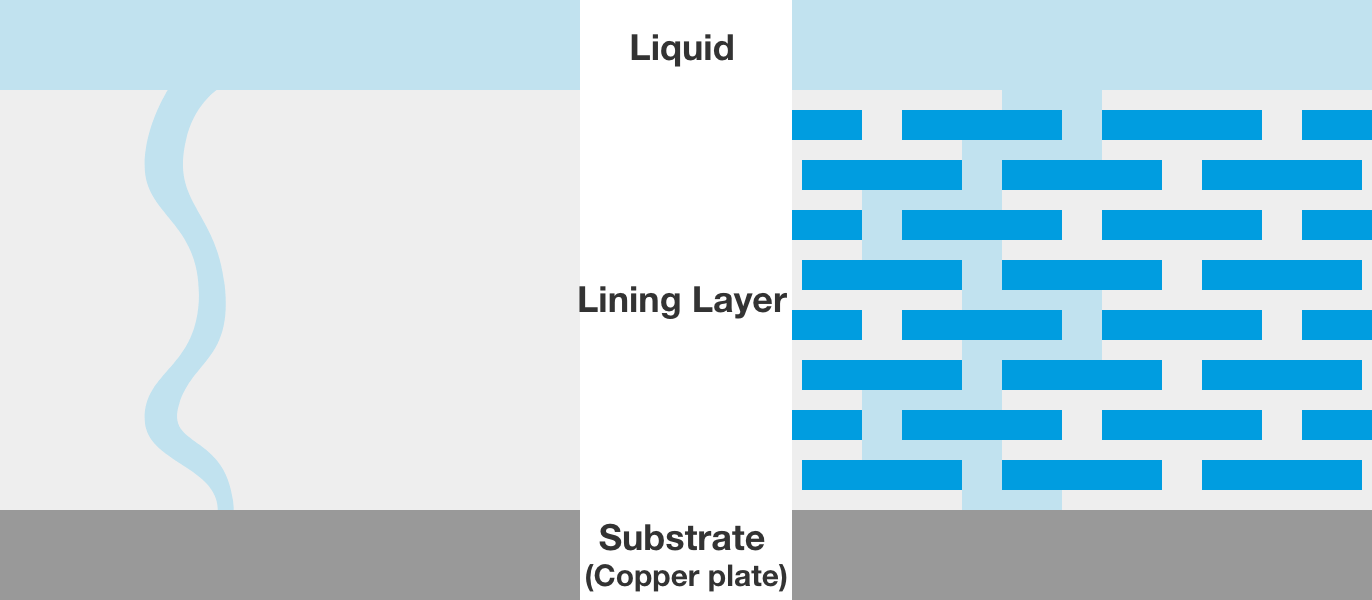

Oriented GLASFLAKE® forms a barrier, preventing infiltration of water vapor and chemical substances. During the infiltration process, GLASFLAKE® creates an obstacle to increase the length of the infiltration path, delaying their reach to the substrate. It contributes to longer service life of the lining layer.

GLASFLAKE® prevents cracking and peeling of the lining layer and improves abrasion resistance.

Image of liquid permeation (with or without GLASFLAKE®)

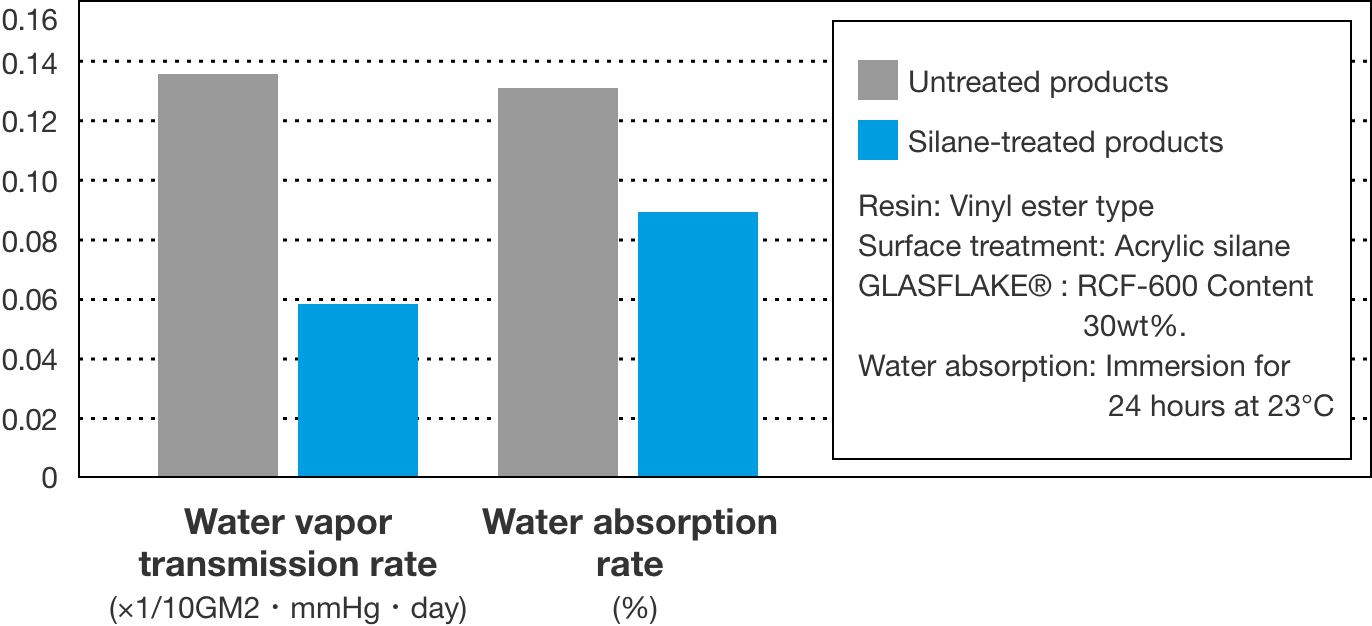

Effect of GLASFLAKE® surface treatment

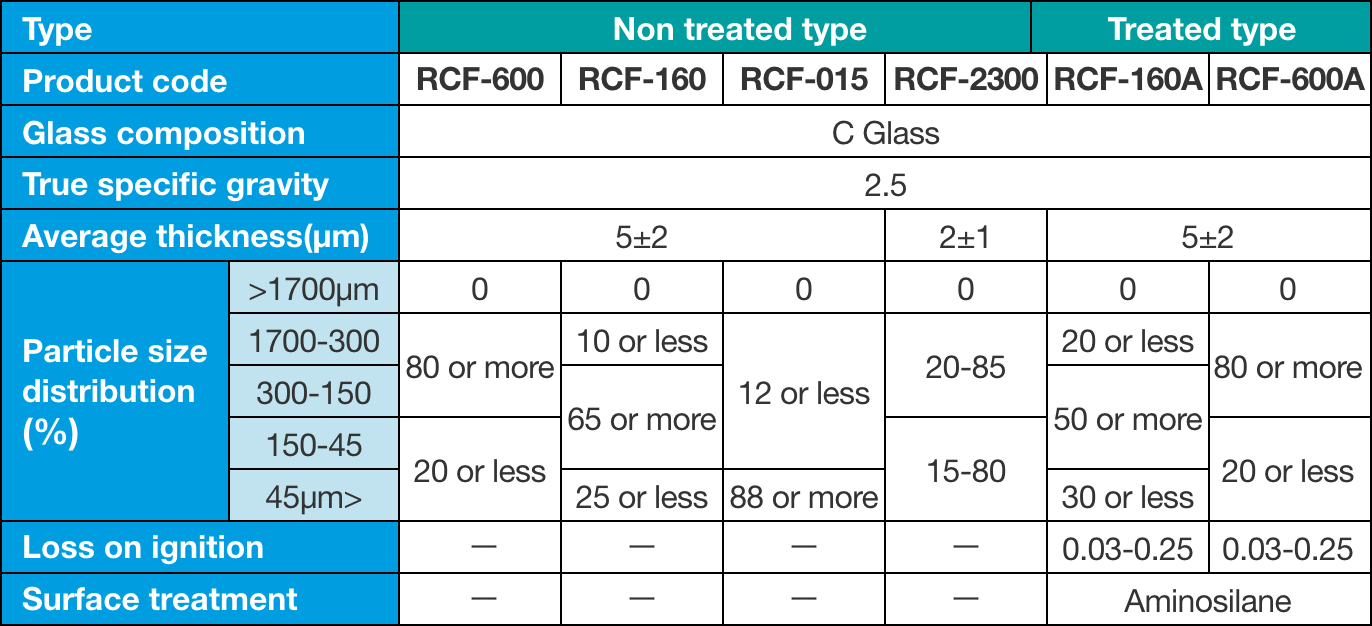

C GLASFLAKE® product line up

C GLASFLAKE® products are produced with average thickness 2µm and 5µm. For products with thickness 2µm, average particle size is 300µm. For thickness 5µm, average partcle size 15µm, 160µm, and 600µm are available.

Surface treatment improves adhesion to resin, contributing to longer service life of paints and lining.

C GLASFLAKE® Product lineup

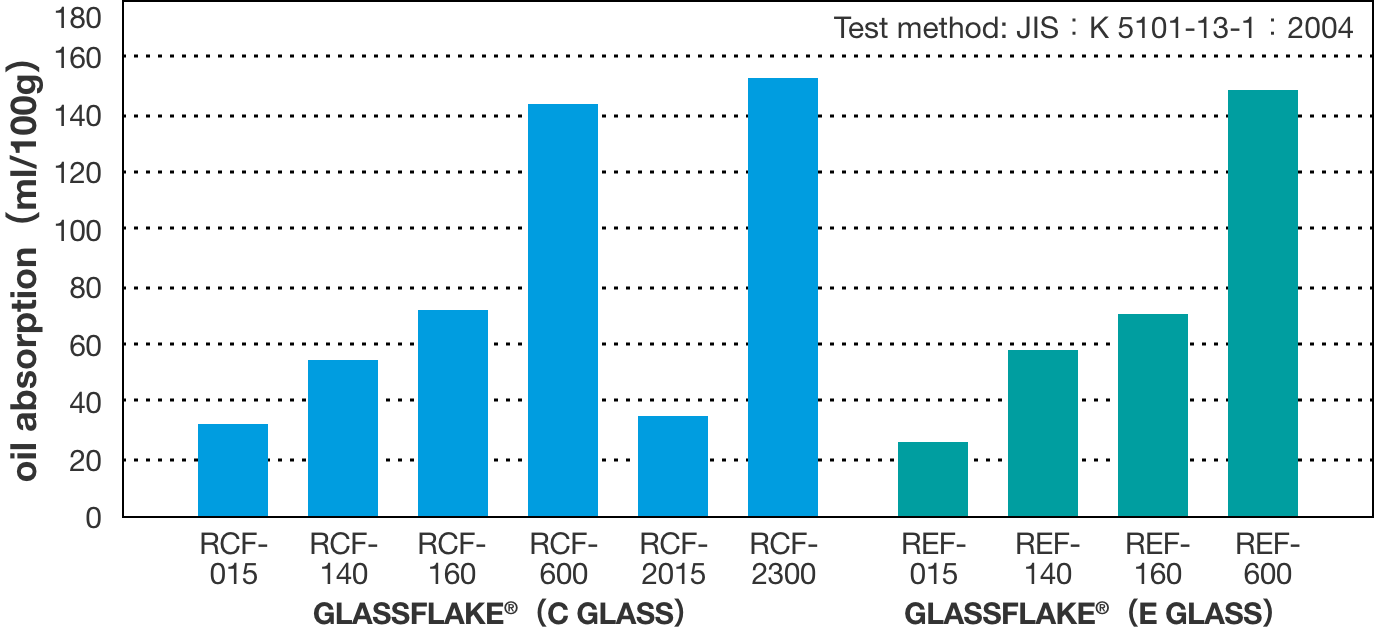

Oil absorption of GLASFLAKE®

Results of oil absorption measurement using linseed oil

Test Method : JIS : K 5101-13-1 : 2004

Oil absorption of GLASFLAKE®

Glossary

Particle diameter

In the case of glass flakes, the particle size is defined as the long side of the glass in plate form.

Aspect ratio

The ratio is obtained by dividing particle size by the thickness of the glass flakes, and so this refers to the particle size/thickness.

Barrier properties

The property is related to prevent or delay ingression of substances (such as water and water vapor) from coating surface to substrate.

Lining

Thick coating/treatment covers outside or inside surface of object with substance which can settle on the object.

Flake shape glass filler products list

NSG offers a variety of flake shape (scale-shaped) glass fillers to suit different granular sizes and applications.

For details on each product, please see the links in the table below.

| Products | Mean particle thickness [um] | Mean particle size [um] | Product use |

| GLASFLAKE® | 2~5 | 15~600 | Anticorrosion / corrosion resistant paint |

| FLEKA® | 5 | 160~600 | High-performance resins |

| FINEFLAKE™ | 0.7 | 160 | High-performance resins |

| DURAFLAKE® | 0.35 | 140 | High-performance resins |

| Low-dielectric glass flakes | 0.3~0.8 | 1~160 | Printed circuit boards / Interlayer insulation |