Our miGIO™ micro optical elements are products achieved by combining Nippon Sheet Glass's strengths in material development, imprint manufacturing technology, and optical design capabilities.

These products feature high durability, high precision, and excellent mass production capabilities.

At Nippon Sheet Glass, we can provide comprehensive support from optical design to mass product production.

NSG's Strengths

Point 1

Materials with excellent durability

- Internally developed proprietary sol-gel glass and organic-inorganic hybrid materials

- Feature high heat resistance, chemical resistance, weather resistance, and low thermal expansion. Compatible with Telcordia standards and reflow at 330°C.

Point 2

Mass production support

- Excellent quality stability and mass productivity ensured by mold-based printing.

- Optical element formation on large surface area of up to 8 inches at once

- Optical elements on wafer alignment with high degree of accuracy of ±1μm or less. Optical element formation in necessary areas of wafer only.

Point 3

High optical design capabilities

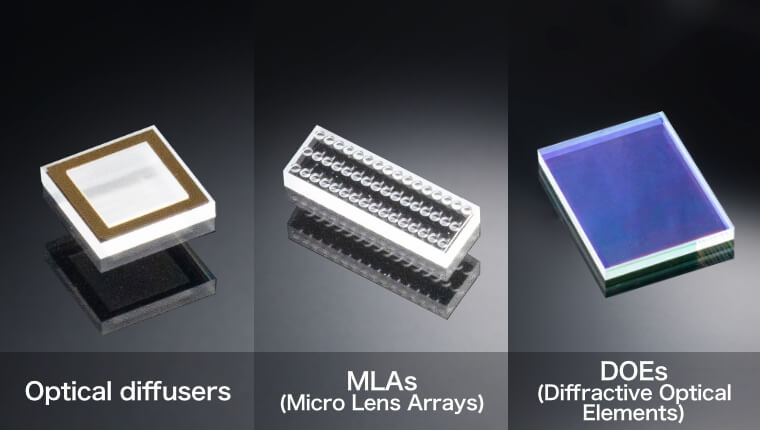

- Design and manufacture of a variety of optical elements, including Optical diffusers, DOEs (Diffractive Optical Elements), MLAs, and moth-eye structures

- Optical element design to suit your needs by Nippon Sheet Glass's optical design engineers

01

Manufacturing of individual optical elements

Features

Excellent component properties

ur micro optical elements feature high heat resistance, chemical resistance, weather resistance, and low thermal expansion. The elements are highly valued, particularly in applications requiring high heat resistance such as high-power lasers, as well as in applications demanding strict durability and reliability like medical equipment and industrial machinery.

High-precision components

With the use of molds in manufacturing, Nippon Sheet Glass mass produces high-precision components with consistent quality.

Various shapes possible

As optical components, our moldable products include MLAs, Optical diffusers, DOEs (Diffractive Optical Elements), and moth-eye structures as well as high-precision structures such as V-grooves and rectangular shapes. As inorganic imprint products, our moldable products include those with challenging features such as structures with heights of several micrometers and structures having high aspect ratios of around five. (We can achieve heights of hundreds micrometers using hybrid material.)

Product Image

Core technologies

Imprinting is a technology that uses a mold to transfer the shape of the mold onto components.

By using our uniquely developed sol-gel glass, we can form fine glass structures on substrate surfaces.

Imprint manufacturing process

Example of component specifications

The basic specifications are shown in the table below. If you have any requests regarding other structures or specifications, please don't hesitate to contact us.

| Inorganic material | |||

|---|---|---|---|

| Refractive index standard |

Refractive index high |

Silica-glass-like | |

| Purpose | Diffraction grating, DOE, Structural AR (e.g. moth-eye) etc. | ||

| Shape | Rectangle, V-groove, Blazed, Moth-eye etc. | ||

| Shape height | ~7μm | ~2μm | ~500nm |

| Aspect ratio | ~(10) | ~2 | ~1 |

| Substrate thickness | 0.1mm〜 | ||

| Substrate size | Max.120mm x 120mm | ||

| Substrate type | Fused silica/BK7/D263Teco etc. | Fused silica | |

| Refractive index | 1.4 | 1.4〜1.5 | 1.45 |

02

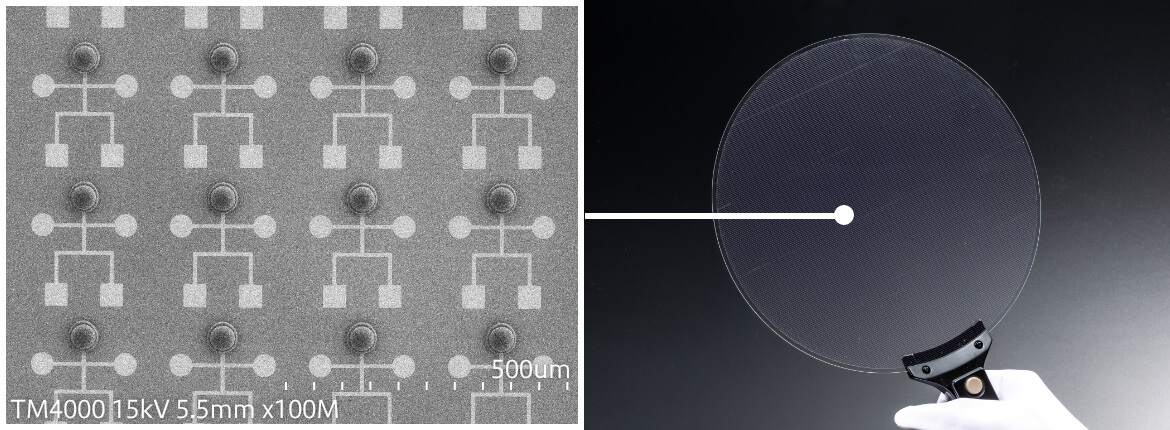

LoW (Lens-on-Wafer)

Nippon Sheet Glass's Lens on Wafer (LoW) is a type of Wafer-Level Optics (WLO) technology that forms precision, microscopic optical elements only in the targeted areas of wafer-level wiring substrates.

This technology is often used in situations where lenses and other items are directly molded onto wafer-level wiring substrates.

Features

High heat resistance

Through the development of organic-inorganic hybrid materials, our products offer high heat resistance.

Our products are compliant with Telcordia standards and accommodate reflow temperatures of 330℃ or higher.

High-precision molding only on required areas of wafer

t Nippon Sheet Glass, we can form optical elements on wafers up to 8 inches in a single process.

Optical elements on wafer alignment can be performed with a high degree of accuracy of ±1 μm or less.

We can also form optical elements in necessary areas only, avoiding regions such as wiring sections of the substrate.

Product images

Core technologies

Imprinting is a technology that uses a mold to transfer the shape of the mold onto components.

Imprint manufacturing process

Example of component specifications

The basic specifications are shown in the table below.

If you have any requests regarding other structures or specifications, please don't hesitate to contact us.

| Item | Technical capability range | Example/Remarks |

|---|---|---|

| Substrate type | Optical glass, silicon, etc. | D263, BF33, etc. |

| Substrate size | ≦Φ8" (Φ200mm) | Φ8" x t0.50mm |

| Chip size | By design | Dicing |

| Lens arrangement | By design | 12ch, 16ch, tight-lattice, etc. |

| Lens shape | Spherical, aspherical, vortex, etc. | Φ0.24, Φ0.06mm, etc. |

| Lens height | ≦0.2mm | Usually less than 0.1mm |

| Alignment accuracy | ±0.002mm | For alignment marks |

| Localized molding | Island lenses, dicing line formation, etc. | Φ0.055 x t0.03mm, pitch 0.25mm |

| Molding pitch | ≧0.09mm | Less than 0.09mm must be confirmed |

| Heat-resisting property | Reflow support | 330℃ 3min, under N2 atmosphere |

| Reliability | Telcordia GR-1211 | Passed |

03

Service

Main applications

Our technology is effective in applications that use high-power lasers and require high weather resistance and excellent reliability.

It is expected to be used in a variety of fields, including 3D sensing , LiDAR, projectors ,laser TVs, and optical communications.

Image of LoW mass production flow

We can accept work-in-progress wafers from customers, form optical elements on the wafers at Nippon Sheet Glass, and return the wafers to you.

After optical element formation, we can perform shape and property evaluations on all products using automated inspection equipment.

We can also provide inspection certificates.

Step1

Inquiry

- Application

- Shape

- Wafer size

- Quantity

- Other consultation

Step2

Interview

- NDA

- Data consultation

Step3

Order

- Specification determination

- Estimate issuance

- Order

Step4

Manufacturing

- Data creation

- Wafer receipt

- Wafer processing

Step5

Delivery

- Evaluation data

- Wafer delivery

One-stop service from design to mass production

At Nippon Sheet Glass, we can provide comprehensive support from optical design to mass production.

In addition to element manufacturing, we can also handle additional processing such as AR coating on element surfaces.

Design

Optical design

Structural design

Mold

Machining

Laser patterning

EB patterning

Proprietary materials

High precision

High durability

Large mold capabilities

Lens

High form accuracy

High intimacy

Low residual stress

High reliability

Reflow resistance

Low water absorption

Chemical resistance

Molding

Alignment accuracy

Thickness control

On target

lithography

Double-side molding

Handling

Functional wafer

Substrate with wiring pattern

Thin substrate

Weak substrate

8 inch wafer

Incidental processing

Film deposition

Cutting

Spin cleaning

Examination

Optical properties

Positional accuracy

Thickness

Appearance

Auto inspection

Mapping

Design

NSG can provide services from optical design and structural design according to various required specifications.

Mold

NSG manufacture molds using the most suitable method for your specifications. High-precision molds are suitable for mass production because they can be made in large sizes and have excellent durability.

Lens

NSG proprietary organic-inorganic hybrid materials can be transferred with high shape accuracy and have excellent durability, including reflow heat resistance exceeding 330℃.

Molding

Lenses and other optical elements are formed on various substrates such as glass and semiconductors. It is possible to form lenses with controlled alignment or on-target, and also to freely set locations where resin is not placed.

Handling

Even patterned functional wafers and thin, easily broken substrates can be protected and processed.

Incidental processing

NSG also perform incidental processing such as film deposition, cutting, and cleaning upon request.

Examination

Key inspection items such as optical properties, positional accuracy, thickness, and appearance can be evaluated and results mapped using automated inspection equipment.

Contact NSG for consultation

NSG's micro-optical elements have evolved through market needs and customer requests.

No matter how challenging the requirements, we will find solutions through technology and provide the best solutions to benefit humanity and society.

Please don't hesitate to contact NSG to discuss your needs.